5901 Botham Jean Blvd, Dallas, TX 75215

Discover The Solar Panel Recycling Process

February 6, 2025By 2050, the world could be dealing with 78 million metric tons of solar panel waste—equivalent to over 8,600 Eiffel Towers. This looming challenge underscores the urgent need for a sustainable approach to solar panel recycling.

Without proper disposal solutions, the very technology designed to reduce our carbon footprint could become an environmental burden. That’s where Okon Recycling steps in.

Specializing in reclaiming valuable materials from decommissioned energy infrastructure, Okon ensures that solar panels don’t just end up in landfills. Instead, they are dismantled, with key components like silicon, glass, and precious metals extracted and repurposed, feeding back into the renewable energy supply chain.

This process not only reduces waste but also lessens the demand for new raw materials, making solar energy truly sustainable.

Recycling solar panels isn’t just about managing waste—it’s about reshaping the future of renewable energy. Each panel that is properly recycled moves us closer to a circular economy, where energy solutions remain environmentally responsible from production to end-of-life.

By embracing advanced recycling technologies, industries can recover critical resources, lower costs, and reduce environmental impact—all while maintaining the momentum toward a greener future.

Join us as we explore the cutting-edge technologies, challenges, and opportunities shaping the future of solar panel recycling. The end of a solar panel’s life doesn’t have to be the end of its value—it can be the beginning of something even brighter for our planet.

Understanding Solar Panel Components for Effective Recycling

Let’s break down the key components that make up these energy-harvesting powerhouses and explore how understanding their composition is crucial for optimizing the recycling process.

The Building Blocks of Solar Panels

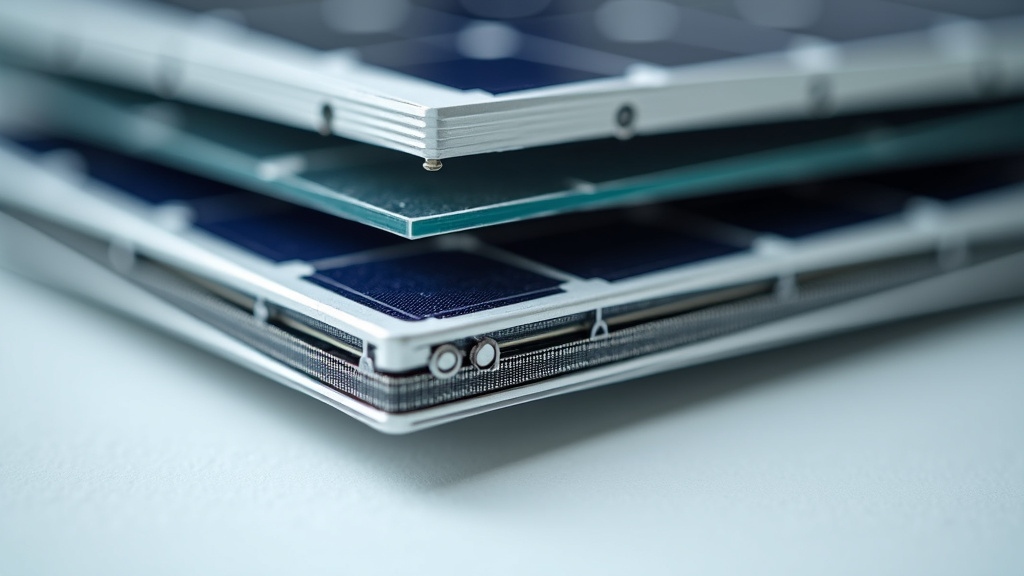

At the heart of every solar panel lies a fascinating array of materials, each serving a specific purpose. The primary components include glass, aluminum, silicon cells, and metal wiring. These elements work in harmony to capture sunlight and convert it into usable electricity.

Glass forms the protective front layer of solar panels, shielding the delicate inner workings from the elements. This isn’t your average window glass – it’s specially designed to be highly transparent and durable, allowing maximum sunlight to reach the silicon cells beneath.

Aluminum plays a crucial role in the panel’s structure, forming the frame that holds everything together. It’s lightweight yet strong, making it ideal for rooftop installations and large solar farms alike. The good news? Aluminum is highly recyclable, often recovered with relative ease during the recycling process.

Silicon cells are the workhorses of solar panels, responsible for the actual conversion of sunlight into electricity. These thin wafers of silicon are typically arranged in a grid pattern and covered with an anti-reflective coating to maximize light absorption. While incredibly efficient, silicon cells pose one of the biggest recycling challenges due to their complex composition.

The Recycling Puzzle: Dismantling for Success

Effective solar panel recycling begins with a careful dismantling process. Each component requires a specific approach to ensure maximum recovery of materials. Think of it as a high-stakes game of Operation, where precision is key to avoiding damage and contamination.

Glass, making up about 75% of a panel’s weight, is often the first target. Once separated, it can be crushed and repurposed for various applications, from new solar panels to construction materials. The aluminum frame, as mentioned earlier, is typically removed and sent directly to aluminum recycling facilities.

The real challenge lies in tackling the silicon cells and associated wiring. These components contain valuable materials like silver and copper, but they’re often fused together with polymer layers for weather protection. Advanced recycling facilities are developing innovative techniques to separate these elements, including thermal and chemical processes.

| Component | Recyclability |

| Silicon solar cells | Can be reused by melting down |

| Metal framing (Aluminum) | Highly recyclable |

| Glass sheets | Recyclable, but challenging due to lamination |

| Copper wiring | Recyclable |

| Plexiglas | Recyclable with correct process |

Why Component Knowledge Matters

Understanding the intricate makeup of solar panels isn’t just academic – it’s the key to unlocking truly effective recycling. By knowing exactly what materials are present and how they’re arranged, recycling facilities can:

- Develop more efficient separation techniques

- Maximize the recovery of valuable materials

- Reduce contamination between different components

- Design safer processes for handling potentially hazardous elements

- Create new markets for recycled solar panel materials

As the solar industry continues to grow, so does the importance of optimizing our recycling strategies. By diving deep into the components that make up these clean energy marvels, we’re paving the way for a more sustainable future – one where today’s solar panels become the raw materials for tomorrow’s clean technologies.

The Multi-Stage Approach to Recycling Solar Panels

Let’s break down this intricate dance of disassembly and reclamation.

Stage 1: Dismantling and Initial Separation

The journey begins with careful dismantling. Skilled technicians remove the aluminum frame and junction box, immediately diverting these easily recyclable components to established metal and electronics recycling streams. This step alone recovers a significant portion of the panel’s weight and value.

The real challenge lies in the panel’s core – a tightly-bonded sandwich of glass, silicon cells, and polymer layers. Innovation plays a key role here. Some facilities use advanced organic recycling methods to gently separate these layers, achieving recovery rates above 95% for valuable materials.

Stage 2: Glass Liberation and Purification

With the frame gone, attention turns to the glass – comprising up to 75% of a panel’s weight. Thermal or mechanical processes break down the laminate structure, freeing the glass from its polymer prison. The glass is then crushed, cleaned, and sorted by quality. High-grade recovered glass can find new life in fresh solar panels, while lower grades might become fiberglass or construction materials.

This stage exemplifies the circular economy in action. Every metric ton of recycled glass saves 1.2 tons of raw materials and reduces energy consumption in glass production by up to 30%.

Stage 3: Silicon Cell Recovery – The Heart of the Matter

Now we reach the most technically challenging – and potentially lucrative – stage: recovering the silicon cells and their associated metals. Cutting-edge facilities employ a combination of thermal, chemical, and electrical techniques to isolate these valuable components:

- Thermal processing vaporizes the plastic encapsulant, exposing the cells.

- Chemical baths selectively dissolve and separate metals like silver, copper, and lead.

- Specialized etching processes recover the ultra-pure silicon.

The stakes here are high. By 2030, the International Renewable Energy Agency estimates the cumulative value of recoverable materials from end-of-life panels will reach $450 million globally – equivalent to the raw material cost for 60 million new panels.

Stage 4: Refining and Material Streams

The final stage involves refining the recovered materials to meet industry specifications. Silicon undergoes purification for potential reuse in new solar cells or other electronics. Metals are smelted and returned to their respective supply chains. Even the polymer components find new purposes through chemical recycling or energy recovery.

This meticulous process ensures that nearly every component of a decommissioned solar panel can avoid the landfill and reenter the manufacturing cycle. It’s a prime example of how smart design and advanced recycling can turn potential waste into valuable resources.

As the solar industry matures, efficient recycling becomes crucial for its long-term sustainability. Understanding these recycling stages allows manufacturers, policymakers, and consumers to make informed decisions that support a truly circular solar economy. The future of clean energy depends not just on harnessing the sun’s power, but on our ability to recapture and reuse the materials that make it possible.

| Asset Type | Estimated Recovery Value | Recovery Rate |

| Cash | $10 million | 100% |

| Accounts Receivable | $15 million | 75% |

| Inventories | $16.25 million | 65% |

| Property, Plant & Equipment | $22.5 million | 50% |

| Total | $63.75 million | 63.75% |

Challenges and Innovations in Solar Panel Recycling

One major hurdle in solar panel recycling is the high-temperature processes required to break down the durable adhesives binding panel components. These energy-intensive methods not only drive up costs but also potentially negate some of the panels’ lifetime carbon savings.

However, this challenge has sparked innovative solutions that could transform solar waste into valuable resources.

Chemical Innovations: Dissolving the Problem

Researchers are making breakthroughs in chemical recycling techniques. For instance, a team at the University of New South Wales has developed a process using inexpensive chemicals to separate and recover over 90% of the materials in silicon-based panels – all without the need for extreme heat. This innovation could dramatically reduce the energy footprint of recycling while boosting material recovery rates.

Mechanical Marvels: Precision Dismantling

On the mechanical front, companies like Veolia are pioneering advanced robotic systems capable of precisely dismantling panels and sorting components with remarkable efficiency. These automated solutions not only increase throughput but also enhance worker safety by reducing exposure to potentially harmful materials.

Another promising development comes from a Japanese firm that has created a water-jet technology to cleanly separate the glass from the rest of the panel structure. This method preserves the integrity of the glass for easy recycling, addressing one of the most voluminous components of panel waste.

The Road Ahead: Challenges as Catalysts

While significant hurdles remain, the challenges in solar panel recycling are driving unprecedented innovation across the industry. Recent research highlights that integrating recycling considerations into panel design could be a game-changer. By creating panels with easier disassembly in mind, manufacturers can dramatically simplify end-of-life processing.

The push for sustainable recycling solutions is also fostering collaboration between academia, industry, and policymakers. This holistic approach is crucial for developing comprehensive recycling frameworks that address technical, economic, and regulatory barriers simultaneously.

As we confront the solar recycling challenge, it is clear that innovation and sustainability go hand in hand. The inventive spirit that revolutionized energy production through photovoltaics is now being applied to ensure those panels do not become an environmental burden at the end of their productive lives.

By viewing these challenges as opportunities for growth and technological advancement, the solar industry is paving the way for a truly circular clean energy economy.

Environmental and Economic Benefits of Solar Panel Recycling

Solar panel recycling offers numerous environmental and economic benefits, contributing to a more sustainable future for renewable energy.

Reducing Landfill Waste and Conserving Resources

Recovering valuable materials from decommissioned panels conserves raw resources and reduces the need for virgin material extraction. This process helps preserve natural habitats and lowers the carbon footprint associated with mining and refining new materials.

According to the International Renewable Energy Agency (IRENA), recycling can recover over 90% of the materials used in solar panels, including glass, aluminum, and various semiconductor materials. This high recovery rate significantly reduces the demand for new raw materials in panel production.

Creating Green Jobs and Economic Opportunities

The solar panel recycling industry has great potential for job creation and economic growth. As the sector expands, it generates employment opportunities across various skill levels, from collection and transportation to specialized recycling processes.

A report by the Solar Energy Industries Association (SEIA) suggests that the U.S. solar industry could create over 100,000 jobs in manufacturing and recycling by 2030. These green jobs not only contribute to economic development but also support the transition to a more sustainable workforce.

The recycling industry also creates new revenue streams through the recovery and resale of valuable materials. For instance, the cumulative value of recoverable materials from end-of-life panels could exceed $15 billion by 2050, according to research published in Sustainable Cities and Society.

Supporting the Circular Economy

Solar panel recycling plays a key role in fostering a circular economy within the renewable energy sector. By closing the loop on material usage, it reduces waste, conserves resources, and minimizes environmental impact throughout the product lifecycle.

This approach aligns with global sustainability goals and enhances the overall environmental performance of solar energy. It also addresses concerns about the long-term sustainability of photovoltaic technology, ensuring that the benefits of solar power are not overshadowed by end-of-life waste issues.

Implementing effective recycling programs can lead to a more resilient and sustainable solar industry. It encourages manufacturers to design panels with recyclability in mind, further improving the efficiency of the recycling process and reducing waste.

Enhancing the Sustainability of Solar Energy

By addressing the end-of-life challenges of solar panels, recycling significantly enhances the overall sustainability of solar energy. It helps mitigate potential environmental risks associated with improper disposal and reinforces solar power’s position as a truly clean energy source.

Recycling also contributes to reducing the carbon footprint of solar panel production. A life-cycle assessment by the National Renewable Energy Laboratory (NREL) found that recycling can decrease the energy payback time of solar panels by up to 30%, further improving their environmental benefits.

As we continue to harness the power of the sun, it’s crucial to recognize that the true potential of solar energy lies not just in its generation, but also in responsible end-of-life management. Solar panel recycling stands as a testament to our commitment to a sustainable energy future.

By embracing recycling practices, we not only address environmental concerns but also unlock economic opportunities, support job creation, and foster innovation in the renewable energy sector. It’s a win-win solution that propels us towards a cleaner, greener, and more prosperous future.

Moving Toward a Sustainable Solar Future

As solar power drives the transition to clean energy, sustainability must extend beyond installation—it must include end-of-life management. Without effective recycling, millions of metric tons of solar panel waste could undermine the very environmental benefits these systems provide.

That’s where Okon Recycling comes in. By reclaiming valuable materials from decommissioned solar panels, Okon helps reduce waste, conserve resources, and support a circular economy. Advanced recycling processes recover critical components like silicon, glass, and precious metals, minimizing the need for raw material extraction and further lowering the carbon footprint of solar technology.

A truly sustainable solar future requires collective action. Policymakers must implement recycling incentives, manufacturers should design panels with recyclability in mind, and consumers can choose eco-conscious solutions that prioritize long-term sustainability.

The future of solar energy isn’t just bright—it’s circular. To learn more about responsible solar panel recycling, contact Okon Recycling at 214-426-6566. Together, we can ensure that solar energy remains a force for good, powering a cleaner, greener world.