5901 Botham Jean Blvd, Dallas, TX 75215

Understanding the Importance of Recycling Rare Earth Magnets

February 3, 2025Have you ever wondered what happens to your old smartphone or that electric car battery when it reaches the end of its life? These high-tech marvels, along with countless other gadgets we rely on daily, contain a hidden treasure: rare earth magnets. But why should we care about recycling these tiny powerhouses?

Rare earth magnets, despite their name, aren’t actually rare in the Earth’s crust. However, extracting them is a different story. Mining these elements often leaves behind a trail of environmental destruction, from toxic waste to radioactive byproducts. It’s a hefty price for our modern conveniences, isn’t it?

This is where recycling becomes essential. By giving these magnets a second life, we’re not just reducing the need for environmentally damaging mining practices. We’re also securing a sustainable future for the technologies that shape our world. From MRI machines saving lives to wind turbines powering our homes, rare earth magnets are the unsung heroes of the tech revolution.

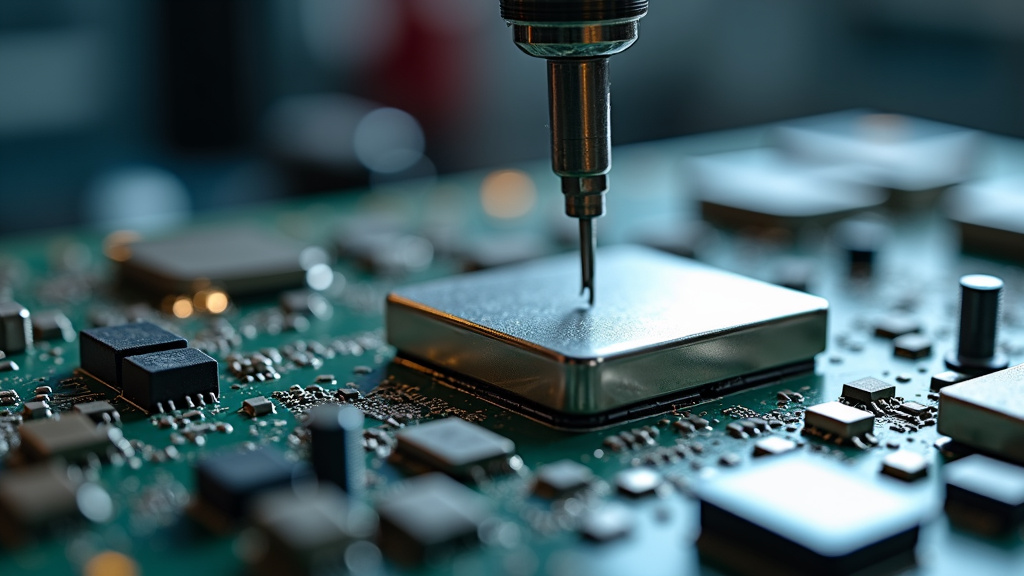

However, recycling these magnets isn’t simple. It requires specialized knowledge and advanced processes. That’s where companies like Okon Recycling come into play. As North America’s largest recycler of neodymium magnets, they’re leading the charge in transforming discarded tech into valuable resources.

Challenges and Solutions in Rare Earth Magnet Recycling

Rare earth magnets, essential components in many modern technologies, present unique challenges in recycling. These powerful magnets, found in devices ranging from hard drives to wind turbines, contain valuable elements crucial for green technologies. However, less than 1% of rare earth elements are currently recycled globally, highlighting the urgent need for efficient recycling processes.

One of the primary hurdles in recycling rare earth magnets is the complex extraction process. These magnets are often deeply embedded within devices, making their removal a labor-intensive and costly endeavor. Moreover, ensuring the purity of the recovered materials poses another significant challenge. Recent studies suggest that the demand for rare earth elements could increase by a factor of up to 7 by 2040, underscoring the importance of developing effective recycling methods.

Hydrometallurgical processes have emerged as a promising solution for recycling rare earth magnets. This method involves using aqueous solutions to dissolve and separate the valuable elements from other materials. While effective, these processes can be resource-intensive, requiring significant amounts of energy and chemicals. However, innovative companies are making strides in optimizing these techniques.

Pioneering Efficient Recycling Methods

At the forefront of rare earth magnet recycling innovation, companies like Okon Recycling are developing groundbreaking methods to streamline the recycling process. These advancements focus on improving both the efficiency of element extraction and the purity of the recovered materials. By refining existing techniques and exploring new approaches, significant progress has been made in recycling efficiency.

One notable example is the development of a novel hydrometallurgical process that significantly reduces the environmental impact of recycling. This method, designed specifically for neodymium-iron-boron (NdFeB) magnets, has shown promising results in laboratory tests. It not only recovers a higher percentage of rare earth elements but also does so with less energy consumption and fewer chemical inputs.

Another innovative approach involves the use of hydrogen decrepitation, a process that breaks down the magnet’s structure at the atomic level. This technique allows for easier separation of the rare earth elements from other materials, potentially reducing the need for intensive chemical treatments. While still in the early stages of development, this method shows great promise for large-scale application.

Overcoming Economic Barriers

Despite the technical advancements, economic factors remain a significant obstacle to widespread adoption of rare earth magnet recycling. The cost of recycling often exceeds that of mining and refining new materials, creating a disincentive for large-scale recycling operations. However, as technologies improve and economies of scale are achieved, the economic viability of recycling is expected to improve.

Companies like Okon Recycling are working to address these economic challenges by developing more cost-effective processes and exploring innovative business models. By creating partnerships across the supply chain and leveraging advanced technologies, they aim to make rare earth magnet recycling not just environmentally beneficial but also economically attractive.

The future of rare earth magnet recycling looks promising, with ongoing research and development efforts focused on overcoming current challenges. As technologies continue to evolve and awareness of the importance of recycling grows, we can expect to see significant improvements in recycling rates and efficiencies in the coming years.

| Company | Recycling Method | Key Features |

| IonicTech | Liquid-liquid extraction | Uses liquid salts and ligands, achieves purity >99.5% |

| ReElement | Continuous chromatography | Separates elements with specialized resin, processes 1,000 tonnes/year |

| Shin-Etsu | Hydrometallurgy | Uses acids and solvents, operational since 2008 |

| HyProMag | Hydrogen processing of magnetic scrap | Demagnetizes and forms alloy powder |

Innovations in Large-Scale Material Recycling

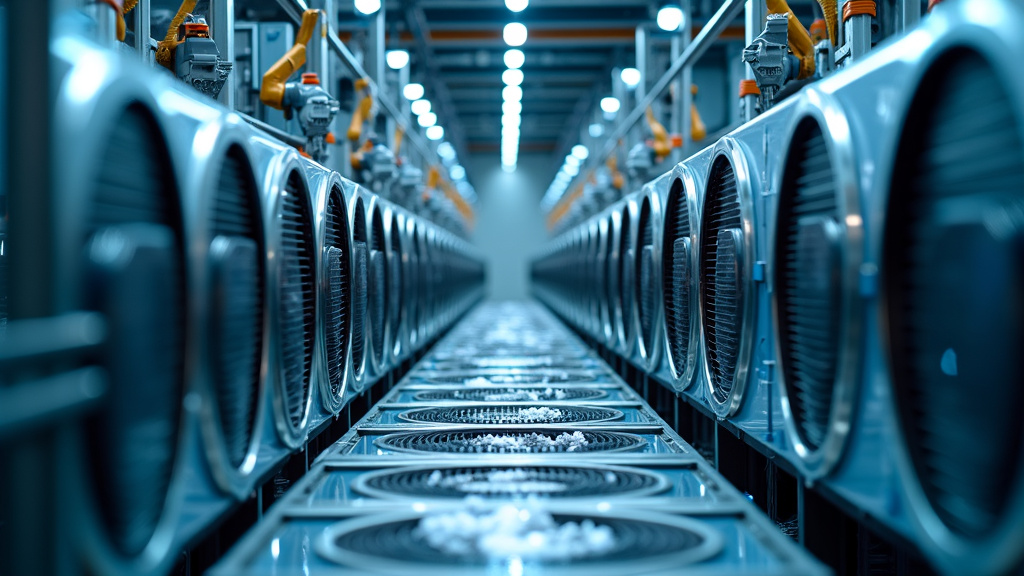

The recycling industry is undergoing a significant transformation, particularly in the realm of large-scale material processing. As our world faces growing environmental concerns, innovative techniques are emerging to tackle the challenge of recycling complex, industrial-sized materials. Construction chillers and air conditioning units, once destined for landfills, are now being revitalized through advanced recycling processes.

At the forefront of this green transformation is Okon Recycling, a company that’s redefining sustainable waste management. With over a century of experience in the metal recycling industry, Okon has consistently adapted to meet the evolving needs of our planet. Their commitment to innovation is reshaping how we approach the recycling of large, complex materials.

Consider the task of recycling industrial air conditioning units. These massive units, often weighing several tons, contain a mix of metals, plastics, and potentially harmful refrigerants. Traditional recycling methods struggled to process these efficiently, but Okon’s state-of-the-art solutions are transforming the industry.

Cutting-Edge Technologies Driving Change

One of the most exciting developments in large-scale recycling is the integration of artificial intelligence and machine learning. These technologies are transforming the sorting process, a critical step in effective recycling. Advanced AI-powered optical sorting systems can now identify and categorize materials with unprecedented accuracy and speed.

For construction chillers, which often contain a complex mix of materials, this technology is a game-changer. AI-driven systems can quickly distinguish between different types of metals, plastics, and other components, streamlining the recycling process and maximizing material recovery.

But it’s not just about sorting. Innovative demanufacturing techniques are also crucial. Robotic systems, guided by sophisticated algorithms, can now disassemble large units with precision, separating components for recycling or refurbishment. This level of automation not only increases efficiency but also improves worker safety by reducing exposure to potentially hazardous materials.

Environmental Impact and Industry Benefits

The advancements in large-scale material recycling are having a profound impact on environmental sustainability. By implementing these advanced recycling solutions, industries are significantly reducing their carbon footprint. The recycling of just one industrial air conditioning unit can save several tons of raw materials and prevent harmful substances from leaching into soil and water systems.

Moreover, this shift towards sustainable waste management is creating new economic opportunities. The recycling industry is growing, creating jobs and driving innovation. Companies like Okon Recycling are not just processing waste; they’re cultivating a circular economy where materials are reused, repurposed, and given new life.

The benefits extend beyond environmental concerns. Industries adopting these recycling practices are gaining a competitive advantage. Not only do they reduce waste management costs, but they also enhance their reputation as environmentally responsible entities, an increasingly important factor for consumers and investors alike.

Future Trends and Challenges

As we look to the future, the landscape of large-scale material recycling continues to evolve. Emerging trends point towards even more sophisticated recycling technologies. For instance, researchers are exploring the use of chemical recycling processes that can break down complex materials at the molecular level, opening up new possibilities for material recovery.

Another promising area is the development of ‘smart’ recycling facilities. These highly automated plants will use a combination of sensors, AI, and robotics to adapt in real-time to the varying composition of waste streams, maximizing efficiency and recovery rates.

However, challenges remain. The ever-changing nature of materials used in manufacturing means recycling technologies must constantly adapt. There’s also a pressing need for standardization in the industry to ensure consistent quality of recycled materials.

As we continue to innovate and push the boundaries of what’s possible in recycling, companies like Okon Recycling will play a pivotal role. Their commitment to implementing state-of-the-art solutions for complex materials is not just helping industries reduce their environmental impact; it’s paving the way for a more sustainable future.

The journey towards fully sustainable large-scale material recycling is ongoing, but the progress is undeniable. With continued innovation, collaboration, and commitment, we can look forward to a future where no material is too complex to be given a second life. The revolution in recycling is here, and it’s transforming our world, one air conditioner at a time.

| Aspect | Traditional Recycling | AI-driven Recycling |

|---|---|---|

| Sorting Method | Manual sorting, labor-intensive | Automated sorting using AI and robotics |

| Efficiency | Lower efficiency due to human error | Higher efficiency, continuous operation |

| Accuracy | Prone to errors and contamination | High accuracy with advanced image recognition |

| Operational Cost | Higher due to labor costs | Reduced due to automation |

| Scalability | Limited by human resources | Highly scalable and customizable |

| Environmental Impact | Higher carbon footprint | Reduced environmental impact |

Conclusion: Embracing Sustainable Recycling Solutions

As highlighted throughout this article, the advancement of rare earth magnet recycling and large-scale material management is not just a technological feat—it is a crucial step towards a more sustainable future. These innovations are reshaping industries and redefining our approach to resource management.

The environmental benefits of recycling rare earth magnets are significant. By reducing the need for environmentally destructive mining practices, we are preserving ecosystems and minimizing our carbon footprint. This shift towards a circular economy is not just beneficial for the planet; it is essential for the long-term sustainability of industries reliant on these critical materials.

Okon Recycling is at the forefront of this green revolution, pioneering resource-efficient solutions that are making waves globally. Their innovative approaches to recycling rare earth magnets and other critical materials are setting new standards in the industry, proving that sustainability and profitability can coexist.

Discover how Okon Recycling can help you make a difference today and be part of the solution in creating a more sustainable tomorrow.