5901 Botham Jean Blvd, Dallas, TX 75215

Understanding the Rare Metal Recycling Market: Key Insights and Trends

March 12, 2025The rare metal recycling market insights reveal a sector poised for significant growth, with the global market size projected to reach USD 882 million by 2031, expanding at a compound annual growth rate (CAGR) of 7.0% from 2023 to 2031. This increase highlights the critical role of rare metal recycling in our increasingly electronic world, where the demand for these resources continues to rise.

As environmental concerns grow and natural resources dwindle, the rare metal recycling industry has become a vital component of sustainable resource management and the circular economy. Recycling just one ton of rare earth elements can prevent up to 2,000 tons of toxic waste from being produced through mining, emphasizing the significant environmental impact of this practice. This shift towards recycling is not just a trend, but a necessary evolution in managing our planet’s finite resources.

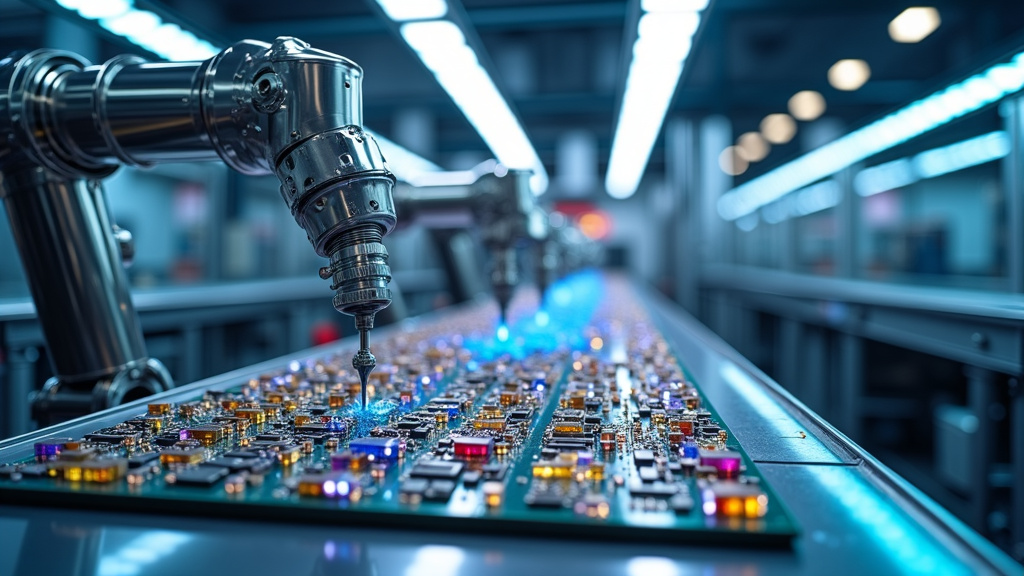

The growing importance of rare metal recycling is driven by several factors. Firstly, the increasing adoption of clean energy technologies such as electric vehicles and wind turbines has greatly increased the demand for rare earth magnets. Secondly, geopolitical concerns over the concentration of rare earth element production in certain regions have spurred efforts to diversify supply chains through recycling. Lastly, advancements in recycling technologies, including innovative processes like flash joule heating and AI-driven sorting systems, are making rare metal recovery more efficient and economically viable than ever before.

Drivers of Growth in the Rare Metal Recycling Market

The rare metal recycling market is growing significantly, driven by key factors reshaping industry dynamics. As demand for these critical materials rises, recycling is essential for sustainable supply chains and reducing environmental impacts. Here are the primary drivers propelling this market forward:

Stricter Environmental Regulations

Governments worldwide are implementing stricter regulations to address the environmental challenges of rare metal mining and processing. These regulations are pushing industries to seek sustainable alternatives, with recycling emerging as a viable solution. For example:

- The European Union’s Waste Electrical and Electronic Equipment (WEEE) Directive mandates the recycling of electronic waste, including rare metals.

- China, the world’s largest producer of rare earth elements, has tightened environmental standards for mining, indirectly boosting the recycling sector.

- The United States has identified rare earth elements as critical materials, prompting initiatives to increase domestic recycling capabilities.

Push for Sustainable Manufacturing Practices

Corporations face increasing pressure to reduce their environmental footprint, leading many to use recycled materials in their sustainability strategies. This trend is evident in industries heavily reliant on rare metals:

- Major tech companies like Apple are using recycled rare earth elements in their products, setting new industry standards.

- Automotive manufacturers are exploring ways to include recycled rare metals in electric vehicle components, especially in battery and motor production.

- The renewable energy sector, particularly wind turbine manufacturers, is investigating recycling solutions for rare earth magnets to create a more circular supply chain.

Increasing Demand in High-Tech Industries

The rapid growth of high-tech industries is fueling unprecedented demand for rare metals, making recycling not just environmentally beneficial but also economically attractive. Key sectors driving this demand include:

- Consumer electronics: Smartphones, laptops, and other devices require significant amounts of rare metals for their production.

- Clean energy technologies: Wind turbines and solar panels rely heavily on rare earth elements for efficiency and performance.

- Electric vehicles: The shift to electric mobility is dramatically increasing the need for rare metals in batteries and motors.

As these industries expand, pressure on primary rare metal sources intensifies, making recycling an increasingly vital component of the supply chain.

Geopolitical Factors and Supply Chain Security

The concentration of rare metal production in a few countries has raised concerns about supply chain vulnerability and geopolitical risks. Recycling offers a way to diversify sources and enhance resource security:

- Countries are investing in domestic recycling capabilities to reduce dependence on foreign suppliers.

- The COVID-19 pandemic has highlighted the importance of resilient supply chains, emphasizing the role of recycling in ensuring material availability.

These drivers collectively contribute to the growth of the rare metal recycling market, fostering innovation in recycling technologies and reshaping the global landscape of rare metal supply and demand. As the industry evolves, it presents challenges and opportunities for stakeholders across the value chain.

Challenges Facing the Rare Metal Recycling Industry

The rare metal recycling industry has experienced significant growth due to rising demand for critical materials in high-tech applications. However, this sector faces major hurdles that require innovative solutions. Let’s examine the key challenges and the emerging technologies addressing them.

Complex Extraction Processes

A primary challenge in rare metal recycling is the complexity of extraction. Unlike common metals, rare earths are often mixed with other materials, making separation difficult. Traditional methods depend on harsh chemicals and energy-intensive processes, raising environmental and economic concerns.

Researchers are developing more sustainable approaches to address this. For example, scientists at Iowa State University are exploring the use of a protein called Lanmodulin (LanM) to selectively bind rare earth metals, potentially reducing the need for toxic chemicals.

Another promising development comes from Kyoto University, where a novel Selective Extraction-Evaporation-Electrolysis (SEEE) process has achieved recovery rates of 96% for neodymium and 91% for dysprosium, with purities exceeding 90%. This method offers a more efficient and environmentally friendly alternative to conventional recycling techniques.

High Recycling Costs

The economic viability of rare metal recycling remains a significant challenge. Currently, only about 1% of rare earth elements in old products are recycled, largely due to the high costs of collection, dismantling, and processing.

To address this, companies are investing in automation and scale. Apple, for instance, has developed robots named Taz and Dave specifically designed to recover rare earth magnets from electronic devices, aiming to streamline the recycling process and improve cost-effectiveness.

Additionally, some firms are exploring new business models. Noveon Magnetics, for example, has pioneered a method to directly recycle magnets without complete rare earth separation, reducing costs and slashing energy consumption by about 90% compared to traditional magnet manufacturing.

Need for Advanced Technologies

The complexity of rare metal recycling necessitates cutting-edge technological solutions. From precision sorting to molecular-level separation, the industry constantly needs innovation to improve efficiency and reduce environmental impact.

One focus area is the development of advanced sensors and sorting technologies. These systems can rapidly identify and segregate different types of rare earth-containing materials, improving the overall recycling process.

Another frontier is the application of artificial intelligence and machine learning to optimize recycling processes. These technologies can help predict the most efficient extraction methods based on the composition of recycled materials, potentially reducing costs and improving yields.

Emerging Solutions and Industry Resilience

Despite these challenges, the rare metal recycling industry is demonstrating remarkable resilience and innovation. Collaborative efforts between academia, industry, and government bodies are driving progress in addressing these obstacles.

For example, the Critical Materials Institute, led by Ames National Laboratory, is spearheading research into new recycling technologies and supply chain solutions. Their work on data-driven design and dynamic simulation is paving the way for more efficient and selective extraction processes.

As the industry evolves, it’s clear that overcoming these challenges will require a multifaceted approach. By combining technological innovation, economic incentives, and sustainable practices, the rare metal recycling sector is poised to play a crucial role in securing the supply of these critical materials for future generations.

Recycling Technologies and Recovery Rates

The effectiveness of different recycling methods can vary greatly. Presenting this information in a tabular format helps in understanding and comparison.

| Recycling Technology | Recovery Rate | Notes |

|---|---|---|

| Mechanical Recycling | 9% – 73% | Best economic and environmental performance |

| PET Glycolysis | 9% – 73% | Best economic and environmental performance |

| Lithium-ion Battery Recycling | 40% – 60% | Limited recovery of lithium and graphite |

Future Outlook and Market Projections

The rare metal recycling market is set for substantial growth in the coming years, driven by technological advancements, increased sustainability awareness, and a rising demand for critical materials. Experts project the global market to reach $1.0 billion by 2030, expanding at a compound annual growth rate (CAGR) of 5.3% from 2024 to 2030.

This growth is supported by several key factors. The rapid adoption of electric vehicles and renewable energy technologies is increasing demand for rare earth metals like neodymium, praseodymium, and dysprosium. As these industries expand, the need for sustainable sourcing of these materials becomes crucial. Recycling offers a promising solution to meet this demand while reducing environmental impact.

Technological innovations are also transforming the rare metal recycling landscape. Advanced separation techniques, hydrometallurgical processes, and AI-driven sorting systems are significantly improving the efficiency and economic viability of recycling operations. For example, flash joule heating, a novel technique developed by researchers at Rice University, shows promise in extracting rare earth elements from electronic waste with unprecedented efficiency.

Emerging Opportunities

As the industry evolves, several promising opportunities are emerging:

1. Urban Mining: Treating discarded electronics as a valuable resource for rare metals is gaining traction. With increasing e-waste, urban mining could become a significant source of recycled materials.

2. Circular Economy Integration: Leading companies are embracing circular economy principles, emphasizing the reuse and recycling of rare metals. This trend is expected to drive further investment in recycling infrastructure and technologies.

3. New Applications: As technologies like quantum computing and advanced energy storage systems develop, new applications for rare metals are likely to emerge, potentially expanding the recycling market.

Challenges and Considerations

Despite the positive outlook, the industry faces several challenges. The complex nature of rare earth element recycling, particularly from end-of-life products, remains a technical hurdle. Additionally, fluctuating market prices for rare metals can impact the economic feasibility of recycling operations.

Regulatory frameworks will play a crucial role in shaping the industry’s future. Governments worldwide increasingly recognize the strategic importance of rare metal recycling, with some implementing policies to encourage recycling initiatives and develop domestic supply chains.

Looking ahead, the rare metal recycling industry stands at the cusp of a transformative period. By addressing current challenges and capitalizing on emerging opportunities, the sector is well-positioned to secure a sustainable supply of critical materials for future technologies.

For businesses and investors considering entering this space, the time to act may be now. As Okon Recycling at 214-717-4083 can attest, early movers in this rapidly evolving market stand to gain significant advantages as the industry matures and demand continues to grow.

| Year | Market Size (USD Million) | CAGR (%) |

|---|---|---|

| 2024 | 356.91 | 11.1 |

| 2025 | 396.55 | 11.1 |

| 2026 | 440.42 | 11.1 |

| 2027 | 489.46 | 11.1 |

| 2028 | 544.05 | 11.1 |

| 2029 | 604.51 | 11.1 |

| 2030 | 692.39 | 11.1 |

Embracing Sustainable Practices in Rare Metal Recycling

The rare metal recycling industry is at a critical point, ready to significantly contribute to a sustainable future. This sector offers an appealing mix of environmental responsibility and economic opportunity. By diverting valuable materials from landfills and reducing the need for harmful mining practices, rare metal recycling helps close the loop in our resource-heavy electronics industry.

The evolution of recycling technologies, such as flash joule heating and AI-driven sorting systems, shows the sector’s rapid progress. These advanced methods are enhancing the efficiency and cost-effectiveness of rare metal recovery, creating new opportunities for recycling materials once deemed too difficult to process.

As the market matures, businesses across industries have a chance to support a more circular economy. Partnering with experienced recyclers like Okon Recycling offers invaluable expertise in navigating the complexities of rare metal recycling. Their specialized knowledge and advanced techniques can help companies maximize the value of their electronic waste while minimizing their environmental impact.

The time for action is now. We encourage readers to consider the significant impact that rare metal recycling can have on sustainability efforts and to explore partnerships with industry leaders. By adopting these sustainable practices, businesses can contribute to environmental conservation and position themselves at the forefront of a growing and crucial sector.

To learn more about how your organization can benefit from rare metal recycling solutions, contact Okon Recycling at 214-717-4083. Together, we can transform today’s electronic waste into tomorrow’s valuable resources, paving the way for a more sustainable and prosperous future.