5901 Botham Jean Blvd, Dallas, TX 75215

Rare Metal Recycling: Sustainable Recovery & Reuse

February 21, 2025Recycling just one ton of rare earth elements can prevent up to 2,000 tons of toxic waste from being produced through mining. This statistic highlights the critical importance of rare metal recycling in our increasingly electronic world. As devices become more advanced, the demand for these materials continues to rise, placing pressure on limited natural resources.

Rare metal recycling has become a vital solution for managing the growing mountain of electronic waste we generate each year. By reclaiming valuable elements from discarded devices, we’re not just clearing out our junk drawers – we’re contributing to a more sustainable future.

This practice conserves irreplaceable resources while significantly reducing the environmental damage caused by traditional mining operations.

Why is Rare Metal Recycling Essential?

Imagine if your old smartphone could power the next breakthrough in renewable energy technology. That’s the promise of rare metal recycling. These recovered materials find new life in everything from electric vehicle batteries to wind turbines, fueling the green technologies needed to combat climate change. It’s a powerful example of how innovative waste management can drive progress toward a cleaner, more sustainable world.

Companies like Okon Recycling are at the forefront of this industry, developing specialized solutions to tackle the unique challenges of rare metal recovery. Their advanced techniques go beyond simply shredding old electronics. Using cutting-edge processes, they can extract tiny amounts of valuable elements with precision, turning what was once considered trash into essential materials.

The impact of these efforts extends beyond keeping electronics out of landfills. Effective rare metal recycling reduces the need for environmentally destructive mining practices, conserves energy, and helps stabilize the supply chain for these critical resources. It creates a model for truly sustainable industrial practices, aligning environmental protection with economic benefits.

As consumers, we all have a role to play in this recycling effort. The next time you upgrade your device, consider its journey beyond your hands. By choosing responsible recycling options, you’re not just decluttering – you’re providing the raw materials for the next generation of green technology. In the world of rare metal recycling, even the smallest contribution can significantly impact our planet’s future.

Innovative Techniques in Rare Metal Recovery

The field of e-waste recycling is undergoing significant transformation. As discarded electronics accumulate, scientists and engineers are developing advanced methods to extract valuable rare metals from this urban mine. These innovations are not only about reclaiming resources; they are reshaping our approach to sustainability and waste management.

Two standout techniques in this evolving field are flash joule heating and AI-driven sorting. These processes are revolutionizing electronic waste handling, promising more efficient recovery of precious materials while reducing environmental impact. Let us explore these technologies and their implications for the future of recycling.

Flash Joule Heating: A Bright Spark in Metal Recovery

Flash joule heating is gaining attention in the recycling world. This innovative process uses rapid bursts of electricity to heat materials to extremely high temperatures in seconds. The result is a more efficient and environmentally friendly way to extract rare metals from e-waste.

Imagine a glass tube filled with electronic waste, suddenly illuminated by an intense flash of light. That is flash joule heating in action. This method can reach temperatures of up to 3,000 degrees Celsius, breaking down complex electronics into their constituent elements almost instantaneously.

The beauty of flash joule heating lies in its precision and speed. Unlike traditional recycling methods that often involve harsh chemicals or energy-intensive processes, this technique can separate valuable metals like gold, silver, and rare earth elements with minimal environmental impact. It offers hope for more sustainable recycling practices.

Researchers at Rice University have led the development of this technology. In a groundbreaking study, they demonstrated how flash joule heating could recover rare earth elements from electronic waste with unprecedented efficiency. The process not only extracts these precious metals but does so while consuming significantly less energy than conventional methods.

One of the most exciting aspects of flash joule heating is its versatility. This technique is not limited to just one type of electronic waste. From old smartphones to discarded circuit boards, flash joule heating offers a universal solution for recovering a wide range of valuable materials that would otherwise end up in landfills.

AI-Driven Sorting: Smart Solutions for Complex Waste

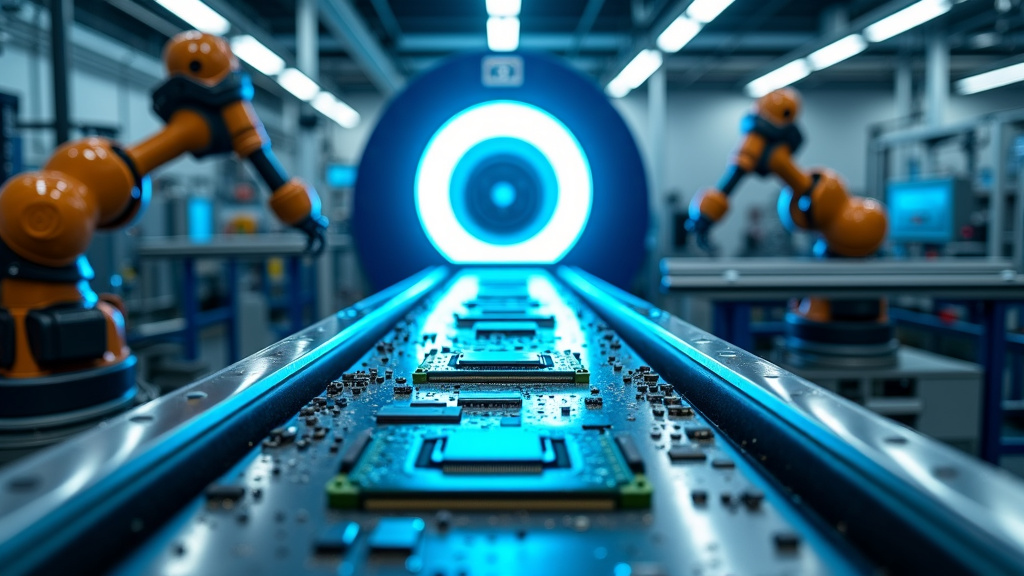

As we embrace artificial intelligence, even our trash is getting a high-tech makeover. AI-driven sorting systems are revolutionizing how we process and recycle electronic waste. These intelligent systems can identify, categorize, and separate different types of e-waste with remarkable accuracy and speed.

Picture a conveyor belt filled with a jumble of discarded electronics. To the human eye, it might look like an overwhelming mess. But to an AI-powered sorting system, it is a treasure trove of data and opportunities. Using advanced image recognition and machine learning algorithms, these systems can distinguish between various components and materials in real-time.

The impact of AI sorting on rare metal recovery is profound. By accurately identifying and separating different types of electronic waste, these systems ensure that each component reaches the most appropriate recycling process. This precision not only increases the efficiency of metal recovery but also significantly reduces contamination and waste in the recycling stream.

One of the key advantages of AI-driven sorting is its ability to learn and adapt. As new electronic devices enter the waste stream, these intelligent systems can be updated to recognize and categorize them accurately. This flexibility is crucial in keeping pace with the rapidly evolving world of consumer electronics.

Moreover, AI sorting systems help address one of the biggest challenges in e-waste recycling: the complex mix of materials in modern electronics. By accurately identifying different components, these systems enable more targeted and efficient recycling processes, maximizing the recovery of rare and valuable metals.

The Synergy of Innovation: Combining Technologies for Maximum Impact

While flash joule heating and AI-driven sorting are impressive on their own, their true potential is realized when combined. This synergy of technologies is creating a new paradigm in e-waste recycling, one that promises to be more efficient, environmentally friendly, and economically viable than ever before.

Imagine an AI system sorting through a batch of electronic waste, identifying components rich in rare metals. These selected items are then processed using flash joule heating, extracting valuable materials with pinpoint accuracy. This integrated approach not only maximizes the recovery of rare metals but also minimizes energy consumption and waste generation.

The impact of these combined technologies extends beyond just efficiency. They open up new possibilities for recycling materials that were previously considered too difficult or expensive to process. For instance, the recovery of rare earth elements, crucial for many modern technologies, is becoming increasingly viable thanks to these innovative techniques.

Furthermore, these advanced recycling methods are helping to close the loop in the electronics lifecycle. By more effectively recovering rare metals from e-waste, we reduce the need for new mining operations, which often come with significant environmental and social costs. It is a step towards a more circular and sustainable electronics industry.

As these technologies continue to evolve and improve, we can expect even more dramatic changes in how we handle electronic waste. From reducing the environmental impact of recycling to creating new economic opportunities in the recycling sector, the future of rare metal recovery looks bright indeed.

The advent of flash joule heating and AI-driven sorting marks a significant leap forward in our ability to recover rare metals from electronic waste. These innovative techniques are not just technological marvels; they represent a shift towards more sustainable and efficient resource management. As we continue to grapple with the growing challenge of e-waste, these technologies offer a promising path forward, turning what was once considered trash into valuable treasure.

The Future Implications of Rare Metal Recycling

Imagine a future where your old smartphone doesn’t just gather dust in a drawer but actively contributes to creating the next generation of devices. This isn’t science fiction—it’s the potential of advancements in rare metal recycling. By adopting more advanced and efficient recycling methods, we can unlock both economic and ecological benefits that could transform industries.

Economically, the advantages are evident. As Okon Recycling highlights, recycling rare earth metals can significantly lower production costs while creating new revenue streams in the recycling sector. This could result in more affordable electronics, a surge in green jobs, and reduced reliance on unstable international markets for raw materials.

Ecologically, the impact could be even more significant. By diverting electronic waste from landfills and minimizing the need for harmful mining practices, we can greatly reduce carbon emissions and protect delicate ecosystems. The recycling industry is rapidly innovating, with breakthroughs in chemical recycling and AI-powered sorting technologies making the process more efficient and effective than ever before.

However, realizing this future requires more than technological advancement—it demands a change in how we perceive our devices and their lifecycles. As consumers, we play a vital role in driving this change. By choosing products designed for recyclability and participating in responsible e-waste disposal, we can support the transition to a more circular economy.

A Call to Action for a Sustainable Tech Future

The path forward requires collective action. Policymakers must implement legislation that drives recycling innovation, tech companies must design products for easier end-of-life recycling, and consumers must adopt mindful purchasing and disposal habits.

Rare metal recycling is more than an environmental necessity—it’s an opportunity to reshape the tech industry. By embracing sustainable practices, we can reduce waste, conserve resources, and build a greener future.

The time to act is now. Partner with Okon Recycling to be part of the solution. Contact us at 214-717-4083 to explore innovative recycling strategies that turn e-waste into a valuable resource. Together, we can transform waste into opportunity.