5901 Botham Jean Blvd, Dallas, TX 75215

Exploring the Impact of Government Incentives for Rare Metal Recycling

February 19, 2025The global rare earth metals recycling market is projected to reach $14.4 billion by 2030, highlighting the growing importance of recycling these critical materials. As demand for rare metals increases due to their essential role in technologies from smartphones to electric vehicles, governments worldwide are introducing innovative incentives to enhance recycling efforts.

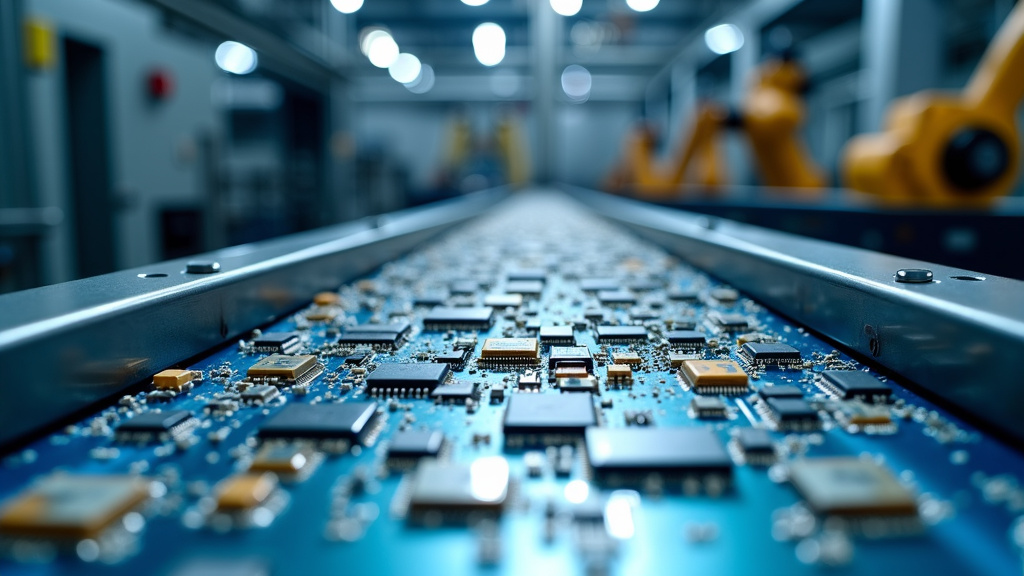

Imagine a world where discarded electronics become valuable resources instead of piling up in landfills. This vision is becoming reality thanks to strategic government initiatives aimed at revolutionizing the rare metal recycling industry. From tax credits that make investing in advanced recycling technology more appealing to grants that support research and development, these programs are reshaping the landscape of resource recovery.

Why the urgency? Recycling rare earth elements can reduce energy consumption by up to 90% compared to mining new materials. It’s not just about conserving resources; it’s about significantly reducing our carbon footprint.

As we explore government incentives for rare metal recycling, we’ll uncover how these programs are both environmentally crucial and economically transformative.

Economic and Environmental Benefits of Rare Metal Recycling

Rare metal recycling offers a practical solution to pressing environmental and economic challenges. By reclaiming valuable materials from discarded electronics and industrial waste, we can reduce the need for environmentally harmful mining and create new economic opportunities.

Environmentally, recycling rare metals provides significant benefits. Mining these elements often involves extensive land disruption, water pollution, and high energy consumption. According to industry experts, recycling can dramatically lower energy requirements compared to primary extraction, sometimes by up to 95%.

For example, recycling one ton of rare earth elements can prevent the production of up to 2,000 tons of toxic waste from traditional mining. This waste reduction not only protects ecosystems but also safeguards human health by limiting exposure to harmful byproducts.

Economic Advantages of Rare Metal Recycling

The economic benefits of rare metal recycling are equally compelling. As global demand for these elements rises, driven by technologies like smartphones and electric vehicles, recycling offers a way to secure a stable domestic supply chain. This reduces dependency on volatile international markets and enhances resource security.

Moreover, the recycling industry is a powerful economic driver. It creates jobs across various sectors, from collection and transportation to high-tech processing facilities. These positions often require specialized skills, contributing to a highly skilled workforce in the green technology sector.

Businesses engaged in recycling can also benefit from reduced raw material costs and potential tax incentives, enhancing their competitiveness in the global market. The cost savings achieved through recycling can be substantial, especially as the prices of virgin rare metals fluctuate.

Innovations Driving the Industry Forward

Technological advancements are rapidly improving the efficiency and economic viability of rare metal recycling. New techniques in hydrometallurgy and pyrometallurgy are making it possible to recover a higher percentage of rare metals from complex electronic waste.

For instance, innovative processes can now extract valuable elements like neodymium and dysprosium from discarded magnets with unprecedented efficiency. These breakthroughs increase the profitability of recycling operations and expand the range of materials that can be effectively recycled.

Looking to the future, the rare metal recycling industry stands at the intersection of environmental stewardship and economic opportunity. By supporting and investing in this sector, we can work towards a more sustainable and prosperous future for all.

Challenges and Solutions in Rare Metal Recycling

The rare metal recycling industry faces significant obstacles that hinder its growth and effectiveness. Chief among these are inconsistent regulations across different regions and the high costs associated with recycling processes. However, experts believe that with the right approach, these challenges can be overcome to support more sustainable resource management.

One of the primary hurdles is the lack of standardized regulations. Different countries and even states within countries often have varying rules regarding the collection, processing, and reuse of rare metals. This regulatory patchwork makes it difficult for recycling companies to operate efficiently across borders and can lead to confusion for consumers and businesses alike.

To address this issue, policymakers need to work towards creating more unified regulatory frameworks. According to industry experts, developing comprehensive policies that support the growth of the rare metal recycling industry is crucial. These policies should aim to harmonize regulations across regions, making it easier for recycling operations to scale up and operate more effectively.

Another significant challenge is the high cost associated with rare metal recycling. The processes required to extract and purify these metals from complex products like smartphones or electric vehicle batteries can be expensive and energy-intensive. This economic barrier often makes recycling less attractive compared to mining new materials, especially when market prices for raw materials are low.

Innovative Solutions and Incentives

To overcome the cost hurdle, a multi-faceted approach is necessary. Governments can play a crucial role by offering financial incentives to companies engaged in rare metal recycling. These could include tax breaks, subsidies for recycling infrastructure, or grants for research and development of more efficient recycling technologies.

Technological innovation is also key to reducing costs. Advances in recycling processes, such as improved separation techniques and more efficient chemical extraction methods, can significantly lower the economic barriers. Investing in research and development of these technologies should be a priority for both public and private sectors.

Another potential solution is the implementation of extended producer responsibility (EPR) programs. These initiatives make manufacturers responsible for the entire lifecycle of their products, including disposal and recycling. EPR programs can incentivize companies to design products with recycling in mind and contribute to the costs of recycling infrastructure.

Building a Circular Economy

Ultimately, the goal is to create a circular economy for rare metals, where these valuable resources are continuously recycled and reused. This approach not only conserves natural resources but also reduces the environmental impact associated with mining and processing virgin materials.

To achieve this, collaboration between governments, industries, and consumers is essential. Public awareness campaigns can educate consumers about the importance of recycling electronic waste and other products containing rare metals. Meanwhile, industries can work together to develop standardized recycling protocols and share best practices.

By addressing these challenges through a combination of regulatory solutions, economic incentives, and technological innovations, the rare metal recycling industry can overcome its current hurdles. This shift towards more sustainable resource management is crucial for ensuring a stable supply of these critical materials for future generations.

| Process | Energy Consumption | Environmental Impact |

| Recycling Copper | 85% less energy than mining | Lower greenhouse gas emissions |

| Mining Copper | High energy consumption | Significant land disruption and pollution |

| Recycling Platinum | 3 megajoules per ounce | Reduced environmental strain |

| Mining Platinum | 12 megajoules per ounce | High environmental toll |

Achieving Sustainable Resource Management through Government Incentives

By implementing targeted policies and financial support, governments can encourage investment in advanced recycling technologies. This helps address the technical challenges that often make rare metal recovery economically difficult. Innovations in hydrometallurgical and pyrometallurgical processes, supported by government funding, can greatly improve the efficiency and cost-effectiveness of extracting valuable materials from complex electronic waste.

Moreover, government-led initiatives can establish a robust regulatory framework for the rare metal recycling sector. Clear guidelines and standards ensure consistent recycling practices across regions, promote a level playing field for businesses, and enhance the quality of recycled materials. This regulatory clarity is vital for attracting long-term investments and fostering innovation within the industry.

Looking ahead, the future of sustainable resource management depends on our ability to create a circular economy for rare metals. Government incentives can play a transformative role by encouraging businesses and consumers to participate in recycling programs. For example, tax breaks for companies using recycled rare metals or deposit-refund systems for electronic devices can significantly increase recycling rates.

As we move towards a more sustainable future, it’s crucial that we support these initiatives. By advocating for stronger government support for recycling programs and participating in local e-waste collection efforts, we can contribute to a more secure and environmentally friendly supply chain for rare metals. Remember, every device recycled is a step towards a more sustainable world and a resilient technology sector.

The Path Forward: Collaboration and Innovation

The challenges of sustainable rare metal management require collaboration among policymakers, industry leaders, researchers, and consumers. Government incentives can spur innovation and cooperation across sectors to develop more efficient recycling technologies and practices.

One promising avenue is ‘urban mining,’ where rare metals are recovered from discarded electronics in urban areas. Government support for research in this field could lead to breakthroughs making urban mining a viable alternative to traditional extraction methods, reducing reliance on environmentally damaging mining practices.

Furthermore, international cooperation is crucial in addressing the global nature of the rare metals supply chain. Governments can foster partnerships between countries to share best practices, harmonize regulations, and create a global market for recycled rare metals. Such collaboration could help mitigate supply risks and reduce geopolitical tensions.

As consumers, we can drive change by supporting products and companies that prioritize recycled materials. By making informed choices and demanding transparency in supply chains, we can create market pressure for more sustainable practices. Government incentives promoting consumer education and awareness can amplify this effect, creating a cycle of demand for recycled rare metals.

Conclusion: A Sustainable Future for Rare Metal Recycling

The future of rare metal recycling depends on government incentives, technological innovation, and industry collaboration. By investing in advanced recycling technologies and implementing strong regulatory frameworks, we can reduce reliance on environmentally harmful mining while securing a stable supply of these critical materials.

Businesses and consumers alike have a role to play in supporting sustainable recycling initiatives. Whether through responsible e-waste disposal, choosing recycled materials, or advocating for better policies, every effort contributes to a more resilient and eco-friendly future.

Want to make a real impact? Contact Okon Recycling at 214-717-4083 to explore cutting-edge recycling solutions that drive both sustainability and profitability. Together, we can build a cleaner, greener future for rare metal recovery.