5901 Botham Jean Blvd, Dallas, TX 75215

SmCo Magnets: A Revolutionary Force in Technology

February 27, 2025Imagine a world where your smartphone never loses its magnetic sensors, even in scorching heat. Picture wind turbines that keep spinning efficiently in harsh climates. This isn’t science fiction—it’s the remarkable reality of SmCo magnets. What exactly makes these magnets so special?

SmCo magnets, short for samarium cobalt, are the unsung heroes powering countless devices we rely on daily. These mighty magnets pack a powerful punch in a small package, outperforming many of their counterparts in extreme conditions. Their true superpower lies in their unwavering stability.

Unlike some magnets that weaken when temperatures rise, SmCo magnets stand strong. They maintain their magnetic might even when things heat up, making them invaluable in high-tech applications where reliability is essential. From the depths of the ocean to the edges of space, SmCo magnets keep our technology running.

It’s not just about withstanding heat. SmCo magnets are champions of consistency, resisting demagnetization like seasoned warriors. This means they maintain their magnetic properties even when exposed to strong opposing magnetic fields—a crucial feature in many precision instruments and industrial applications.

Applications of SmCo Magnets in Various Industries

Samarium cobalt (SmCo) magnets have established a significant presence in various high-tech industries due to their exceptional magnetic properties and resilience in demanding environments. These rare earth magnets excel where conventional magnets falter, particularly in applications requiring strong magnetic fields at elevated temperatures.

Aerospace: Pushing Performance Boundaries

In the aerospace sector, SmCo magnets are essential components in critical systems. Their ability to maintain magnetic strength at high temperatures makes them ideal for jet engine sensors and actuators. For instance, SmCo magnets were utilized in NASA’s Deep Space 1 mission, powering the ion-propulsion engine that enabled the spacecraft to encounter comet Borrelly.

These magnets also find applications in radar systems, where their stability ensures reliable performance in the extreme conditions encountered during flight. Additionally, SmCo magnets are crucial in aircraft generators and motors, contributing to more efficient and lightweight propulsion systems.

The aerospace industry’s reliance on SmCo magnets stems from their unparalleled combination of high magnetic strength and resistance to demagnetization at temperatures up to 350°C. This unique property set allows for the design of compact, powerful, and reliable aerospace components.

Automotive: Innovating Electric Vehicles

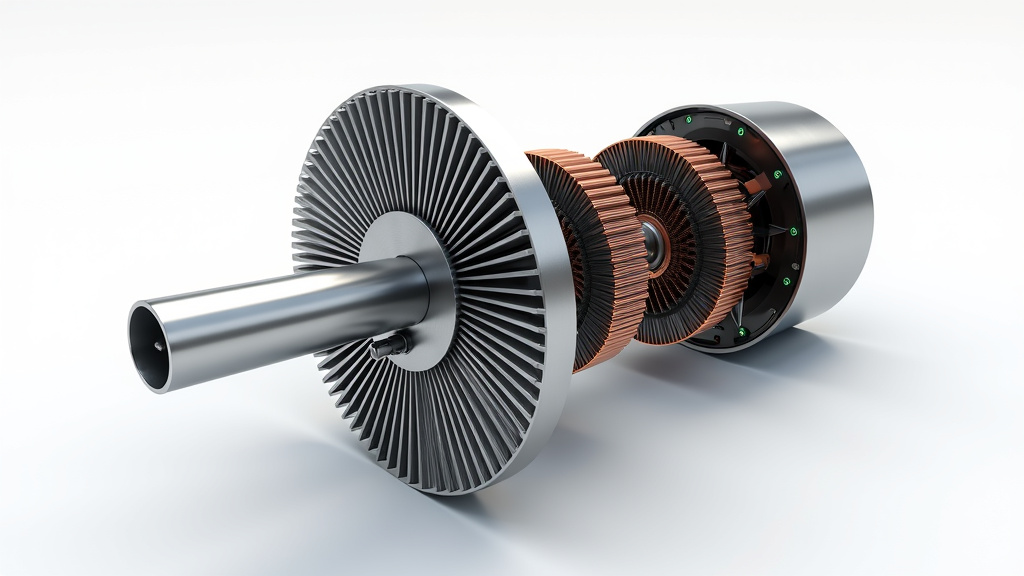

The automotive industry, particularly in the realm of electric vehicles (EVs), has embraced SmCo magnets for their exceptional performance characteristics. These magnets are vital components in EV motors, where they help create the powerful magnetic fields necessary for efficient energy conversion.

SmCo magnets’ high temperature resistance is particularly valuable in the demanding environment of an electric motor, where heat generation is a constant challenge. Their use allows for the design of more compact and powerful motors, contributing to the overall efficiency and range of electric vehicles.

Beyond motors, SmCo magnets are also utilized in various automotive sensors and actuators. Their stability and resistance to corrosion make them ideal for applications such as ABS sensors and power steering systems, where reliability is paramount.

Medical Technology: Enhancing Diagnostics

In the medical field, SmCo magnets play a crucial role in advanced diagnostic equipment. Perhaps their most notable application is in Magnetic Resonance Imaging (MRI) machines. The powerful, stable magnetic fields generated by SmCo magnets contribute to the high-resolution images that make MRI an invaluable diagnostic tool.

SmCo magnets are also used in other medical devices such as hearing aids and surgical tools. Their small size and strong magnetic properties allow for the creation of compact, efficient devices that improve patient care and surgical precision.

The biocompatibility and corrosion resistance of SmCo magnets make them particularly suitable for use in implantable medical devices. From pacemakers to cochlear implants, these magnets help create reliable, long-lasting medical solutions.

Industrial Applications: Powering Manufacturing and Energy

The industrial sector leverages SmCo magnets in a variety of applications, capitalizing on their durability and performance in harsh conditions. In the oil and gas industry, these magnets are used in downhole sensors and drilling equipment, where their resistance to high temperatures and corrosive environments is invaluable.

SmCo magnets also find use in wind turbines, where their stability and strong magnetic properties contribute to more efficient energy generation. In industrial motors and generators, these magnets enable the design of more compact and powerful machines, improving overall system efficiency.

The semiconductor industry utilizes SmCo magnets in ion implanters and other manufacturing equipment, where precise magnetic fields are crucial for producing high-quality electronic components.

Conclusion: A Magnetic Force in Technological Progress

From the depths of space to the intricacies of medical diagnostics, SmCo magnets have proven to be versatile and powerful tools across various industries. Their unique combination of high magnetic strength, temperature resistance, and corrosion resistance makes them invaluable in applications where performance cannot be compromised.

As technology advances, the role of SmCo magnets is likely to expand further, driving innovation in existing fields and opening up new possibilities in emerging technologies. The future of these remarkable magnets is as strong and enduring as their magnetic fields, promising continued contributions to industrial and technological progress.

The Advantages of SmCo Magnets Over Other Rare-Earth Magnets

When it comes to high-performance magnets, samarium cobalt (SmCo) excels in demanding environments. While neodymium magnets are often highlighted for many applications, SmCo magnets offer unique advantages that are crucial in certain industries. Let’s explore why these magnets deserve more recognition.

Superior Thermal Stability: Keeping Cool Under Pressure

One of the key benefits of SmCo magnets is their exceptional thermal stability. Unlike neodymium magnets, SmCo magnets maintain their magnetic properties at much higher temperatures. This is a significant advantage for many applications.

Consider this: while neodymium magnets start losing their effectiveness around 80°C, SmCo magnets continue to perform up to 350°C. That’s not just hot—it’s jet engine hot. It’s no wonder aerospace engineers favor these heat-resistant magnets.

It’s not just about withstanding extreme heat. SmCo magnets also have a flatter temperature coefficient curve, meaning their magnetic strength remains more consistent across a wide temperature range. For precision applications where stability is essential, SmCo magnets are the clear choice.

Corrosion Resistance: Toughing It Out in Harsh Environments

If SmCo magnets were action heroes, they’d be the ones walking away unscathed from explosions. Their corrosion resistance is remarkable, especially compared to neodymium magnets. This durability comes from their high cobalt content—the same element that makes stainless steel resistant to rust.

Here’s an interesting fact: SmCo magnets often don’t need protective coatings in corrosive environments. They can be used in saltwater applications or acidic industrial settings without issue. Neodymium magnets, however, require protective coatings to survive.

This corrosion resistance is about reliability as much as longevity. In critical applications where failure isn’t an option, SmCo magnets provide assurance that they won’t degrade due to environmental factors.

Magnetic Stability: Steady as She Goes

SmCo magnets excel in maintaining magnetic properties under challenging conditions. They have higher coercivity than neodymium magnets, meaning they’re harder to demagnetize.

Think of it like this: if magnets were arm wrestlers, SmCo would be the champion that refuses to budge. This stability makes them ideal for applications with strong demagnetizing fields or where long-term reliability is crucial. Medical equipment, anyone?

The Trade-offs: Nothing’s Perfect

SmCo magnets do have drawbacks. They’re generally more expensive than neodymium magnets and don’t reach the same magnetic strength at room temperature. They’re also more brittle, which can make manufacturing and handling challenging.

However, for applications requiring thermal stability, corrosion resistance, and long-term reliability, these trade-offs are often worthwhile. It’s not about being the strongest—it’s about being the most dependable when the going gets tough.

Applications: Where SmCo Magnets Shine

Given their unique properties, SmCo magnets are used in several high-tech and demanding fields:

- Aerospace: From actuators to sensors in aircraft and spacecraft

- Military: In guidance systems and radar equipment

- Medical devices: MRI machines and other precision instruments

- Industrial motors: Especially in high-temperature or corrosive environments

- Underwater equipment: Thanks to their excellent corrosion resistance

In these applications, the stability and reliability of SmCo magnets often outweigh cost considerations. When sending something into space or implanting it in a human body, you want materials you can trust.

As we push technological boundaries and explore more extreme environments, the unique properties of SmCo magnets are likely to become even more valuable. While they might not be the first choice for every application, in high heat, corrosive environments, and unwavering magnetic stability, SmCo magnets reign supreme.

So next time you hear about a satellite orbiting Earth or a breakthrough in medical imaging, consider the unsung heroes—those sturdy, reliable SmCo magnets working tirelessly behind the scenes, proving that sometimes, it’s not about being the strongest, but about being the toughest.

Innovations Enhancing the Functionality of SmCo Magnets

The field of magnetic technology is undergoing a significant transformation, with samarium cobalt (SmCo) magnets leading this shift. Recent breakthroughs have enhanced the efficiency of these powerful magnets, paving the way for their use in cutting-edge applications across various industries.

Enhancing Efficiency

One major advancement in SmCo magnet technology is the improved strength-to-weight ratio. Engineers have achieved this through innovative manufacturing processes that refine the magnet’s microstructure. As a result, today’s SmCo magnets deliver more magnetic power in smaller, lighter packages.

This efficiency boost is not just about power; it’s about precision too. New techniques allow for precise control over the magnetic field distribution within SmCo magnets. This level of fine-tuning opens up possibilities for applications requiring exact magnetic field shapes, such as in advanced medical imaging equipment or sensitive scientific instruments.

Researchers have also enhanced the temperature stability of SmCo magnets. While known for high-temperature performance, recent innovations have extended their operational range. Some cutting-edge SmCo magnets can now maintain their magnetic properties at temperatures approaching 500°C, making them ideal for extreme environments like aerospace and deep-sea exploration.

Exploring New Technological Frontiers

The improved capabilities of SmCo magnets have attracted attention across various industries. In renewable energy, these magnets are being used in advanced wind turbine generators. Their efficiency at high temperatures allows for more compact and powerful generator designs, potentially increasing wind farm energy output.

The automotive sector is also benefiting from SmCo magnets. As electric vehicles become more prevalent, manufacturers use these magnets to create more efficient and powerful electric motors. The high coercivity of SmCo magnets makes them resistant to demagnetization, crucial in the harsh conditions of electric powertrains.

An exciting application is in magnetic refrigeration. This emerging technology promises to revolutionize cooling systems by using the magnetocaloric effect, potentially offering a more environmentally friendly alternative to traditional refrigeration. SmCo magnets, with their high magnetic strength and temperature stability, are ideal for this innovative method.

The Future is Magnetic

Looking ahead, the potential applications for enhanced SmCo magnets seem limitless. From miniaturized magnetic components in consumer electronics to advanced magnetic levitation systems for transportation, these magnets are set to play a crucial role in future technologies.

The story of SmCo magnets continues. With ongoing research into new manufacturing techniques and applications, we can expect even more groundbreaking developments. As these magnets evolve, they’ll unlock new possibilities, driving technological progress across industries and expanding the boundaries of magnetic technology.

The future is indeed magnetic, and SmCo magnets are leading the charge into a new era of innovation and efficiency.

Envisioning a Sustainable Future with SmCo Magnets

As technology advances, SmCo magnets are proving essential in renewable energy, advanced electronics, and energy-efficient devices—pushing the boundaries of what’s possible. Their unique properties enable compact, high-performance solutions, making them crucial for a sustainable future.

Beyond their applications, SmCo magnets drive global sustainability, reducing energy consumption and optimizing resource use. Their role in efficient technologies has a ripple effect, minimizing environmental impact across industries.

Okon Recycling plays a vital role in this progress, ensuring valuable materials from advanced technologies are recovered and reused. As leaders in sustainable metal recycling, they help industries access critical resources while reducing waste.

The synergy between cutting-edge magnetic technology and responsible recycling demonstrates that innovation and sustainability can go hand in hand. By embracing sustainable practices, we can drive both technological progress and environmental stewardship.

Be part of the change! Call Okon Recycling at 214-717-4083 to learn how you can support sustainable metal recycling and contribute to a cleaner, more efficient future.