5901 Botham Jean Blvd, Dallas, TX 75215

Harnessing Electromagnetism: Efficiency in Motors

February 12, 2025Did you know the same magnetic force that holds a refrigerator magnet in place also powers entire cities? Electromagnetism, the invisible link between electricity and magnetism, is the driving force behind everything from electric motors to massive power generators. Without it, modern life—computers, electric cars, industrial machinery—would simply not exist.

At its core, electromagnetism enables energy conversion. When electricity flows through a wire, it generates a magnetic field. Conversely, moving a magnet near a wire induces electric current. This simple yet powerful principle is what powers motors, spins turbines, and drives innovation in energy efficiency.

At Okon Recycling, we recognize the crucial role electromagnetism plays in sustainable technology. By recovering and repurposing essential materials like copper, aluminum, and rare-earth magnets from decommissioned motors and generators, we help keep these valuable resources in circulation—reducing waste and supporting the next generation of efficient energy solutions.

In this article, we’ll explore how electromagnetism shapes our world, from the mechanics of electric motors to the cutting-edge advancements improving their efficiency.

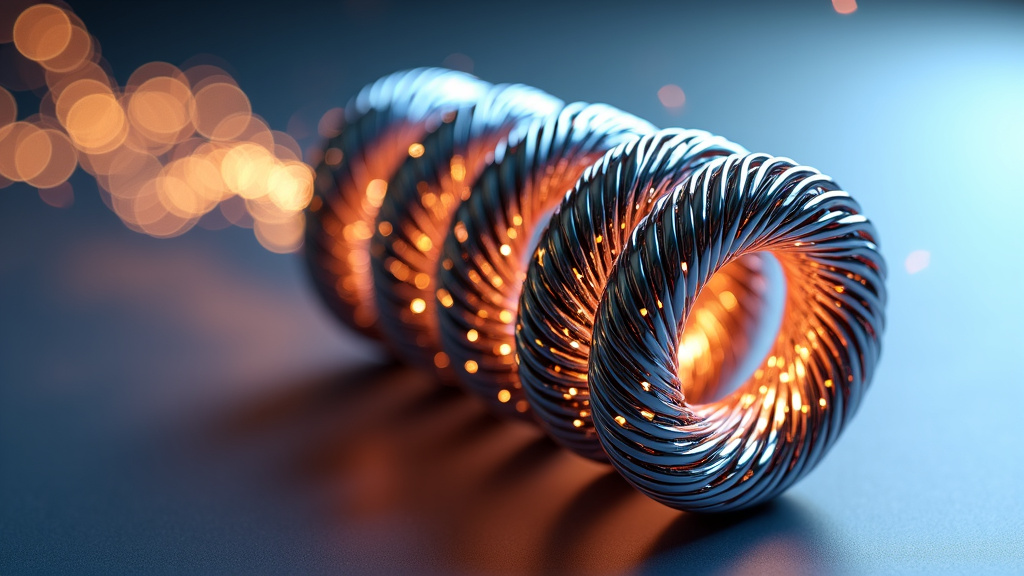

Innovations in Magnetic Coil Designs for Enhanced Efficiency

Magnetic coil designs are at the forefront of advancements in energy conversion systems. As the world shifts towards sustainable energy solutions, engineers and researchers are enhancing magnetic coil efficiency to maximize power output in motors, generators, and other electromagnetic devices.

Let’s explore some of the cutting-edge innovations transforming this field.

Advanced Materials: The Foundation of Modern Coils

The quest for higher efficiency begins at the molecular level with the development of advanced magnetic materials. Traditional copper windings are being supplemented or replaced by exotic alloys and composites with superior magnetic and electrical properties. For instance, researchers have created a novel iron-nickel-cobalt-tantalum multicomponent alloy that exhibits remarkable magnetic characteristics and high mechanical strength. This material allows for the construction of coils that can withstand extreme conditions while maintaining optimal energy conversion rates.

Nanocrystalline and amorphous metals are also making waves in coil design. These materials offer significantly reduced core losses compared to traditional silicon steel, especially at high frequencies. The result is magnetic coils that operate more efficiently across a broader range of power outputs and frequencies.

Innovative Coil Configurations

Beyond materials, the physical arrangement of coils has undergone a transformation. Engineers are now employing advanced computer modeling techniques to design coil configurations that maximize magnetic flux interaction. These optimized geometries ensure that every turn of the coil contributes effectively to the overall magnetic field, minimizing wasted energy and materials.

One particularly promising innovation is the development of fractal-inspired coil designs. These intricate patterns allow for a more uniform distribution of magnetic fields, reducing hotspots and improving overall efficiency. Moreover, 3D printing technologies have opened up new possibilities for creating complex coil shapes that were previously impossible to manufacture using traditional methods.

Superconducting Coils: The Future of High-Efficiency Magnetics

Perhaps the most exciting development in magnetic coil technology is the advancement of superconducting materials. These materials, when cooled to extremely low temperatures, exhibit zero electrical resistance, allowing for the creation of incredibly powerful and efficient magnetic fields.

While currently limited by the need for cryogenic cooling systems, ongoing research aims to develop room-temperature superconductors that could revolutionize energy conversion systems across all industries.

| Material | Inductance (H) | Energy Storage (J) |

|---|---|---|

| Bi2223 | 1 | 5000 |

| YBCO | 1.8 | 9000 |

Real-World Applications and Impact

The impact of these innovations extends far beyond the laboratory. In the automotive industry, more efficient magnetic coils are enabling the development of smaller, lighter, and more powerful electric motors. This translates to electric vehicles with extended range and improved performance. In renewable energy, advanced magnetic coils are boosting the efficiency of wind turbines and improving the reliability of power grid infrastructure.

As we continue to push the boundaries of magnetic coil design, we move closer to a future where energy conversion systems operate at near-theoretical levels of efficiency. This not only reduces energy waste but also opens up new possibilities for clean energy technologies that were once thought impractical due to efficiency limitations.

The journey towards perfect energy conversion is far from over, but with each innovation in magnetic coil design, we take another step towards a more sustainable and energy-efficient world.

Magnet Technology: Core to Sustainable Electric Power Solutions

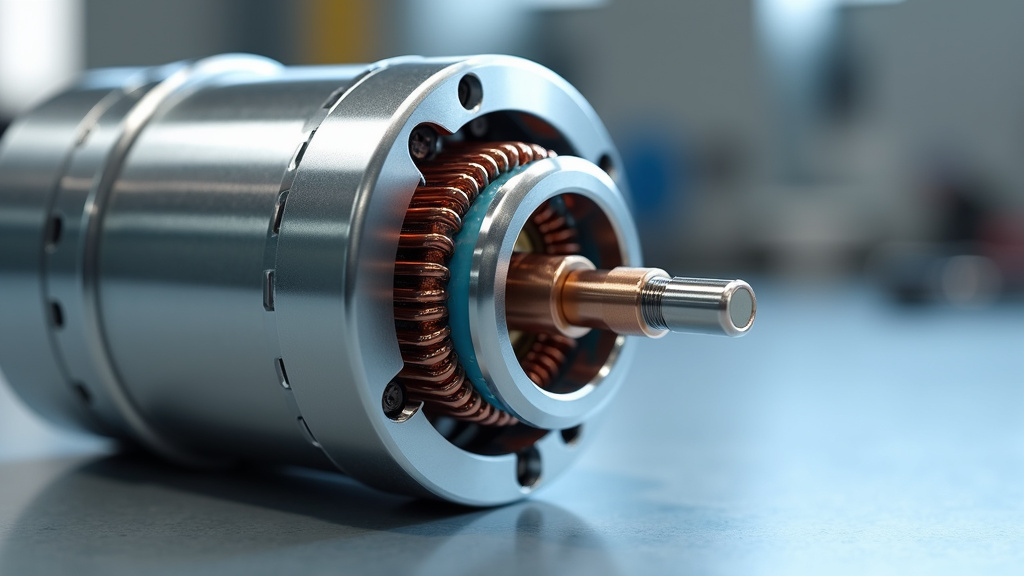

The quest for sustainable energy solutions has placed permanent magnets at the forefront of innovation. These components, particularly those made from high-energy-density materials, have become essential in enhancing the efficiency of modern electric motors and generators. Their ability to create powerful magnetic fields without continuous energy input makes them crucial for a greener future.

Central to this advancement is energy density. High-energy permanent magnets, such as neodymium-iron-boron (NdFeB) alloys, offer significant magnetic strength in a compact form. This allows engineers to design powerful yet compact electric motors and generators. Bulky, inefficient machines are replaced by sleek, lightweight, and highly effective devices.

The impact of these advanced magnets on sustainable technology is significant. In renewable energy, they have enabled more efficient wind turbines. By using permanent magnets, wind farms can generate more electricity from the same wind, maximizing this clean energy source. According to the U.S. Department of Energy, modern wind turbines are taller, more powerful, and efficient, largely due to advancements in magnet technology.

Transforming Transportation

The automotive industry has also embraced high-energy permanent magnets. Electric vehicles (EVs) depend on these components for compact, high-performance motors. Compared to traditional engines, EV motors are smaller but deliver impressive power and torque, enhancing range and performance, making them attractive to eco-conscious consumers.

The benefits extend to public transit systems, where magnetically-driven linear motors power advanced trains. These systems offer smoother, faster, and more energy-efficient travel, suggesting a future of high-speed, low-emission transport.

Enhancing the Grid

High-energy permanent magnets are critical in power generation and distribution. As we move towards a distributed energy grid with more renewables, generator efficiency is vital. Permanent magnet generators offer higher efficiency and reliability, ensuring clean energy is harnessed with minimal losses.

These magnets are also vital in emerging energy storage technologies. Advanced flywheel systems use magnetic bearings to reduce friction, storing excess renewable energy and releasing it during peak demand, stabilizing the grid.

Sustainability Challenges and Solutions

While beneficial, producing high-energy permanent magnets raises sustainability concerns. Rare earth elements used in powerful magnets are often mined with environmental impacts. Researchers are developing recycling techniques to recover these materials from old electronics, promoting a circular economy.

Additionally, scientists are exploring alternative materials that offer similar performance without rare earths. Manganese-based compounds show promise as a more abundant, eco-friendly option for certain applications, highlighting a commitment to sustainable magnet technology.

Looking ahead, permanent magnets will play a growing role in sustainable technology. From efficient home appliances to medical devices and research equipment, these components drive innovation across fields. By enabling compact, efficient, and powerful devices, permanent magnets accelerate our transition to a sustainable future.

The integration of high-energy permanent magnets with sustainable technology offers a promising path to a cleaner, more efficient world. As research progresses and new applications arise, these materials will increasingly shape sustainable solutions. For more on magnet technology and its role in sustainable energy, Okon Recycling provides valuable insights and resources.

| Motor Type | Efficiency |

| Standard Electric Motors | 90% |

| Advanced Concept from Belgium | 98% |

| DC Motors | Lower Efficiency |

| AC Motors | Higher Efficiency |

| Electric Vehicles | 85% conversion of electrical to mechanical energy |

| Gas Combustion Engines | Less than 40% |

The Circular Economy: Building a Sustainable Future with Recycling

Our exploration of recycling in motor and generator production highlights its importance as a crucial step toward sustainability. The circular economy model, emphasizing material reuse and waste reduction, offers a promising future for manufacturing.

Integrating recycling into motor and generator production is transforming resource management. Companies like GE Aerospace are leading the way, utilizing technologies like additive manufacturing and generative design to reduce waste and enhance efficiency.

This circular approach benefits more than just factories. By extending material and component lifespans, we reduce waste and reliance on new resources, driving sustainable growth and spurring innovation across supply chains.

The future of manufacturing in a circular economy is promising. Technologies like artificial intelligence and the Internet of Things are set to transform product design, production, and recycling, making waste reduction and efficiency tangible goals.

As we approach this sustainable transformation, everyone has a role. Whether you’re a manufacturer, consumer, or policymaker, you can support the circular economy by adopting sustainable practices, advocating for recycling policies, and supporting environmentally conscious companies.

We can create a future where waste is minimized, resources are conserved, and prosperity is shared. The circular economy is our guide to a more sustainable and resilient world. Let’s embrace this vision and act today for a better tomorrow.

For more information on recycling and sustainable manufacturing practices, contact Okon Recycling at 214-736-9509. As a leader in the international metal recycling industry, we’re committed to innovative, value-based recycling solutions for a better world.