5901 Botham Jean Blvd, Dallas, TX 75215

What is Driving Growth in the Rare Earth Metals Market?

April 16, 2025The global rare earth metals market is on an impressive growth trajectory. Current projections indicate the market will reach USD 16.26 billion by 2032, expanding at a compound annual growth rate (CAGR) of 8.75% from 2024 to 2032. These critical materials—with their unique magnetic, luminescent, and electrochemical properties—have become indispensable to modern technology.

While relatively unknown to the average consumer, rare earth metals like neodymium, dysprosium, and praseodymium form the backbone of numerous technologies we rely on daily. Their rising importance comes amid the global push toward sustainability and energy efficiency, creating unprecedented demand across multiple sectors.

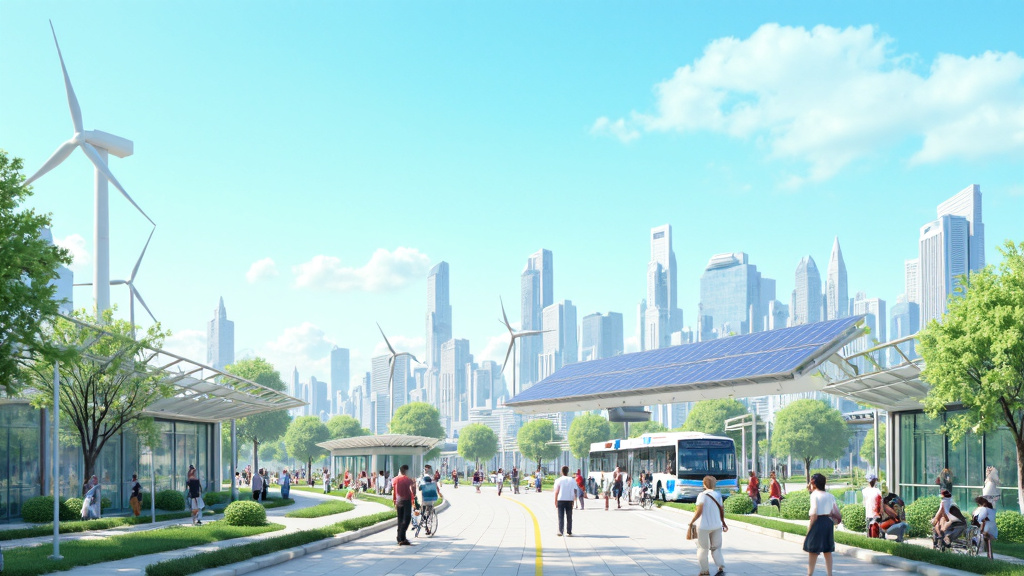

This surge in market value isn’t happening in isolation. It reflects profound shifts in how industries are evolving to meet environmental challenges and technological needs. From the streets of major cities now filled with electric vehicles to the massive wind turbines dotting rural landscapes, rare earth metals quietly enable the clean energy transition reshaping our world.

Which Applications are Fueling Demand for Rare Earth Metals?

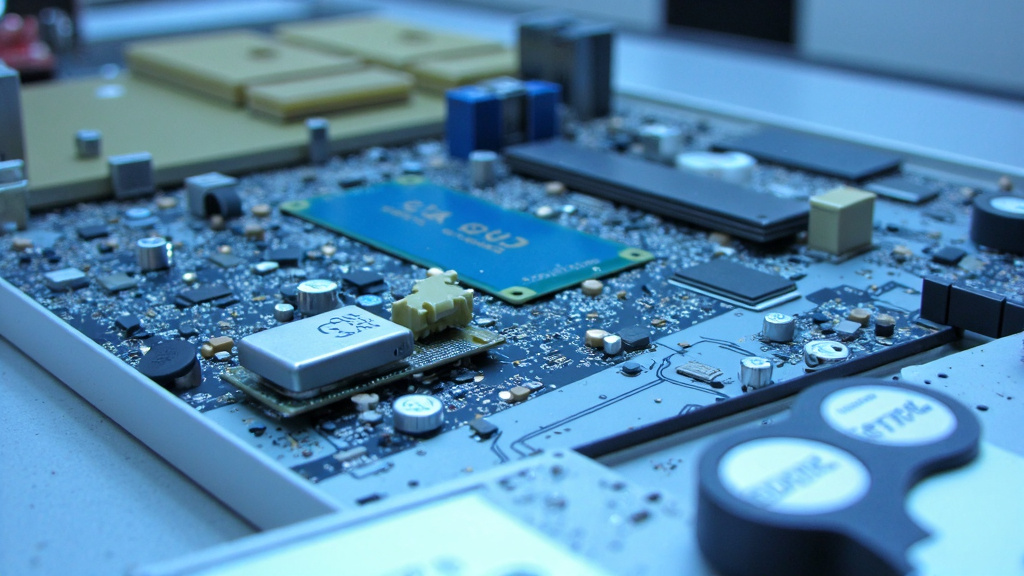

Rare earth magnets have emerged as the dominant force driving rare earth metal demand, representing approximately 29% of global consumption by weight in 2023. These specialized permanent magnets, primarily neodymium-iron-boron (NdFeB) and samarium-cobalt varieties, serve as critical components for converting electrical energy to kinetic energy and vice versa.

The clean energy sector has become the largest consumer of rare earth elements, requiring an estimated 16 kilotons in 2023 alone. Within this sector, two applications stand out as primary growth drivers: electric vehicle motors and wind turbine generators.

Electric Vehicles: Powering the Mobility Revolution

Electric vehicle motors represent one of the most significant applications fueling rare earth demand. NdFeB magnets, containing approximately 31% neodymium by weight, deliver superior power density, torque, and efficiency compared to alternative motor technologies. These performance advantages have helped rare earth magnet motors maintain over 77% market share in electric vehicles for nearly a decade.

The accelerating global transition to electric mobility is creating a substantial demand surge. Industry forecasts indicate the number of electric motors deployed will double by 2035, significantly increasing pressure on rare earth supply chains. This growth trajectory is further intensified by the fact that China—the largest EV market globally—heavily favors rare earth permanent magnet motors in its vehicle fleet.

A single electric vehicle can contain up to a kilogram of rare earth elements, primarily neodymium and praseodymium, with smaller amounts of dysprosium and terbium added to maintain magnetic properties at higher temperatures. As automakers ramp up EV production to meet ambitious climate targets and government mandates, the demand for these critical minerals continues to climb.

Wind Energy: Capturing Renewable Power

Wind turbine generators represent another major application driving rare earth metal consumption, particularly in direct-drive turbine designs. These systems eliminate the need for gearboxes by using large-diameter generators with permanent magnets, significantly improving reliability while reducing maintenance requirements—critical factors for offshore installations.

Modern wind turbines, especially larger offshore models, can contain several hundred kilograms of rare earth magnets. As countries worldwide expand renewable energy capacity to meet decarbonization goals, the wind energy sector’s demand for neodymium, praseodymium, and other rare earth elements continues to grow substantially.

The International Energy Agency and other organizations have highlighted that achieving global renewable energy targets will require massive scaling of wind power capacity, which translates directly to increased rare earth metal demand. This growth creates both opportunities and challenges for the renewable energy transition.

Additional High-Growth Applications

Beyond electric vehicles and wind turbines, several other applications contribute significantly to rare earth demand. Consumer electronics utilize small but critical amounts of rare earth magnets in speakers, vibration motors, and hard disk drive actuators. Medical equipment such as MRI machines requires substantial quantities of rare earth materials for their powerful magnets.

Industrial motors and robotics represent growing sectors where the superior performance of rare earth magnets justifies their use despite higher costs. As automation expands across manufacturing and other industries, this demand segment continues to increase steadily.

The aerospace and defense sectors also rely on rare earth elements for various specialized applications, from guidance systems to communications equipment. These applications typically demand the highest-grade materials with stringent reliability requirements.

Supply Chain Challenges

The concentration of rare earth processing capacity presents significant challenges for meeting growing demand. China currently processes over 90% of global rare earth elements and controls approximately 92% of high-value magnet alloy production. This market concentration has contributed to price volatility, with neodymium prices experiencing severe fluctuations—including a sevenfold increase in 2011 and prices in 2022 reaching four times the average of the previous eight years.

These supply challenges have prompted numerous countries to classify rare earth elements as critical materials. The United States, European Union, Japan, and most recently New Zealand have all established policies aimed at developing more diverse and resilient supply chains for these essential resources.

As demand continues to grow, particularly from the clean energy transition, securing stable supplies of rare earth metals has become a strategic priority for governments and industries worldwide. This focus has accelerated interest in alternative sourcing strategies, including recycling and reprocessing of end-of-life products containing rare earth magnets.

What are the Key Regional Market Trends?

Asia-Pacific dominates the rare earth metals market, capturing around 65% of the global market share as of 2023. This regional powerhouse has established an unrivaled position in both production and consumption of these critical resources, with several countries playing distinct roles in the ecosystem.

China stands as the undisputed leader in the rare earth metals landscape, controlling over 60% of the world’s supply. The country’s strategic investment in mining infrastructure and processing facilities has created a near-monopoly that gives it significant leverage in global supply chains. Chinese dominance stems not only from its abundant natural reserves but also from decades of focused government policies that prioritized rare earth development while many Western nations overlooked these resources.

Beyond China, other Asia-Pacific nations have recognized the strategic importance of rare earth metals and are actively working to secure their positions in the market. Japan, despite lacking substantial natural reserves, has emerged as a key player through innovative approaches to supply security.

Diversification Efforts Across Asia

Japan and South Korea have implemented sophisticated strategies to reduce their dependence on any single source of rare earth metals. Rather than competing directly with China’s production dominance, these countries are fostering strategic partnerships throughout the region and beyond. Japanese corporations, backed by government support, have invested in rare earth mining and processing ventures in countries like Vietnam, Australia, and India.

South Korea has similarly pursued supply diversification through both diplomatic and commercial channels. The country has established research initiatives focused on rare earth recycling technologies while simultaneously securing access to international supplies through long-term agreements with emerging producers.

These diversification efforts reflect growing concerns about supply chain vulnerability in a market dominated by a single nation. The 2010 diplomatic incident when China temporarily restricted rare earth exports to Japan served as a watershed moment, highlighting the risks of overreliance on a single source for these critical materials.

North American Market Developments

North America is showing promising growth potential in the rare earth metals market as both the United States and Canada intensify efforts to reduce dependence on foreign supplies. This shift comes amid growing recognition of rare earths as strategically vital resources for advanced manufacturing, defense applications, and the green energy transition.

The United States has designated rare earth elements as critical minerals and implemented policies to rebuild domestic supply chains. Mining operations at Mountain Pass in California have been revitalized, while new processing facilities are being developed to handle rare earth separation and refinement – capabilities that had largely disappeared from North America.

Canada is leveraging its substantial geological resources to position itself as a reliable alternative supplier. Canadian mining companies are advancing several rare earth projects with support from government initiatives aimed at establishing complete supply chains within North American borders.

These North American developments are directly tied to broader geopolitical tensions and concerns about economic security. The region’s growth trajectory in the rare earth market reflects not just commercial considerations but strategic imperatives to secure access to materials essential for technological leadership.

European nations, while representing a smaller share of the global rare earth metals market, are implementing coordinated policies to address supply vulnerabilities. The European Union has established a raw materials alliance specifically targeting rare earths and other critical minerals, with ambitious plans to develop more sustainable and secure supply chains.

As global competition for rare earth resources intensifies, regional market trends increasingly reflect broader geopolitical and economic strategies rather than purely commercial considerations. The dynamic nature of these regional differences underscores the strategic importance these elements have assumed in the global technology landscape.

What Challenges and Opportunities Exist in the Rare Earth Metals Market?

The rare earth metals market presents a complex landscape of challenges and opportunities as it continues to evolve in response to growing demand and changing global dynamics. Despite projections indicating substantial growth from $6.0 billion in 2024 to $10.9 billion by 2029, several significant hurdles threaten the stability and sustainability of this critical industry.

Supply Chain Vulnerabilities

One of the most pressing challenges facing the rare earth metals market is the fragility of its supply chain. China’s dominance, accounting for approximately 70% of global production, creates a precarious situation for industries reliant on these materials. This concentration of supply makes the market particularly susceptible to disruptions when geopolitical tensions arise or when China implements policy changes related to mining quotas or export restrictions.

The vulnerability became starkly apparent during recent global events, with manufacturers experiencing delayed deliveries, increased costs, and in some cases, complete inability to source necessary materials. For companies producing electric vehicles, wind turbines, and advanced electronics, these disruptions can halt production lines and trigger cascading effects throughout the manufacturing sector.

Geopolitical Tensions

Rare earth metals have increasingly become pawns in broader geopolitical conflicts. Trade disputes between major economies, particularly between the United States and China, have heightened concerns about access to these critical materials. In 2023, neodymium oxide prices dropped to $56 per kilogram from $78 in the previous year, while terbium oxide fell 38% to $810 per kilogram—fluctuations largely attributed to these geopolitical factors.

The strategic importance of rare earth elements has prompted countries to reevaluate their dependencies and seek greater self-sufficiency. The United States has increased its domestic output to 45,000 metric tons of rare-earth-oxide equivalent in 2024, up from 41,600 metric tons in 2023. However, these efforts still fall short of achieving supply chain independence, as the U.S. continues to rely heavily on imports for refined compounds, metals, and permanent magnets.

Environmental Concerns

The extraction and processing of rare earth elements present significant environmental challenges. Traditional mining practices can lead to habitat destruction, soil erosion, and groundwater contamination. The refining process is particularly concerning, often involving toxic chemicals that produce hazardous waste and radioactive byproducts.

As global environmental awareness grows, the industry faces increasing pressure to address these issues. Stricter regulations on mining practices, particularly in China, have already affected production outputs and contributed to price volatility. The environmental impact of rare earth mining poses both a moral and practical challenge for an industry whose products ironically enable many green technologies.

Emerging Opportunities in Alternative Sourcing

Despite these challenges, the rare earth metals market offers substantial opportunities for innovation and growth. Companies and countries are actively pursuing alternative sourcing strategies to mitigate supply chain risks. Australia has emerged as the second-largest producer, while countries like Canada and Brazil are developing projects to join the market.

The Mountain Pass mine in California represents a significant step toward diversifying supply, though further investment in refining capabilities is needed for true independence. Companies like MP Materials have made strategic expansions to strengthen domestic supply chains, while partnerships between established players and emerging producers show promise for creating more resilient supply networks.

Recycling Innovations

Recycling technologies present perhaps the most promising opportunity within the rare earth metals sector. Current recycling rates for rare earth metals stand below 5%, highlighting an enormous untapped potential. Innovative approaches to recovering these valuable materials from electronic waste, spent batteries, and other sources could significantly reduce reliance on primary mining while addressing environmental concerns.

Research conducted by Oak Ridge National Laboratory has demonstrated that membrane extraction systems can recover over 90% of elements like neodymium, praseodymium, and dysprosium from scrap magnets, with expectations to achieve recovery rates closer to 97%. These recycled materials can reach purity levels of 99.6%, making them suitable for high-performance applications.

Sustainable Practices and Alternative Technologies

The industry is witnessing increased focus on developing sustainable mining and processing methods. Green smelting projects, like the one completed by China Northern Rare Earth, represent steps toward reducing the environmental impact of rare earth production. These initiatives not only address environmental concerns but can also improve public perception and regulatory compliance.

Simultaneously, researchers are exploring alternative materials that could reduce dependence on rare earth elements. While complete substitution remains challenging due to the unique properties of these metals, advancements in material science offer promising alternatives for specific applications. The development of rare earth-free permanent magnets, for instance, could revolutionize multiple industries while alleviating supply pressures.

Strategic Investments and Policy Support

Governments worldwide recognize the strategic importance of rare earth metals and are implementing policies to support domestic production and processing capabilities. The United States has increased employment in its rare earth sector to 570 workers, up from 450 in 2023, though this represents just the beginning of building a resilient domestic industry.

Investment opportunities abound in this sector, particularly in technologies that improve extraction efficiency, reduce environmental impact, or enable effective recycling. Companies developing these solutions stand to benefit from increasing government support and growing market demand for sustainable rare earth sources.

The future of the rare earth metals market will depend on how effectively stakeholders navigate these challenges and capitalize on emerging opportunities. As industries increasingly rely on these critical materials for advanced technologies, the development of diversified, environmentally responsible supply chains will be essential for sustainable growth.

Conclusion: Future Outlook for Rare Earth Metals Market

The future of the rare earth metals market appears exceptionally bright, with projections indicating growth from approximately $8.15 billion in 2025 to $9.57 billion by 2029, representing a steady compound annual growth rate (CAGR) of 4.1%. This growth trajectory is primarily fueled by increasing demand across strategic industries, particularly in electronics manufacturing and the expanding electric vehicle sector. As technological advancements continue to evolve, the application scope for these critical materials will only widen, creating robust market dynamics.

The industry’s sustainability focus is becoming increasingly prominent, with recycling initiatives and circular economy practices gaining traction. Major market players are forming strategic partnerships to secure consistent supply chains while developing innovative recovery methods for these valuable resources. For organizations navigating the complexities of metals recycling and recovery, specialized expertise is essential. For professional guidance on rare earth metal recycling solutions for your business, contact Okon Recycling at 214-717-4083.