5901 Botham Jean Blvd, Dallas, TX 75215

Understanding High-Efficiency Rare Metal Recycling

February 20, 2025What if the discarded smartphone in your drawer held the key to powering tomorrow’s clean energy future? This isn’t science fiction—it’s the reality of high-efficiency rare metal recycling. As our appetite for technology grows, so does our need for the precious rare earth elements that make our digital world possible.

Rare earth metals, despite their name, are found in everything from wind turbines to electric vehicle batteries. However, their extraction comes at a significant environmental cost. Traditional mining practices can produce up to 2,000 tons of toxic waste for every ton of rare earths recovered. Enter high-efficiency recycling, where innovation meets sustainability.

Companies like Okon Recycling are pioneering advanced technologies to recover these valuable materials from unlikely sources. Imagine transforming obsolete electronics and industrial byproducts into a source of rare metals, ready to fuel the next generation of green tech.

But how does this process work? And why is it becoming increasingly crucial for industries worldwide? As we explore high-efficiency rare metal recycling, we’ll uncover the innovative techniques, environmental benefits, and economic potential that make this field essential for a sustainable future.

Innovative Techniques in Rare Metal Recycling

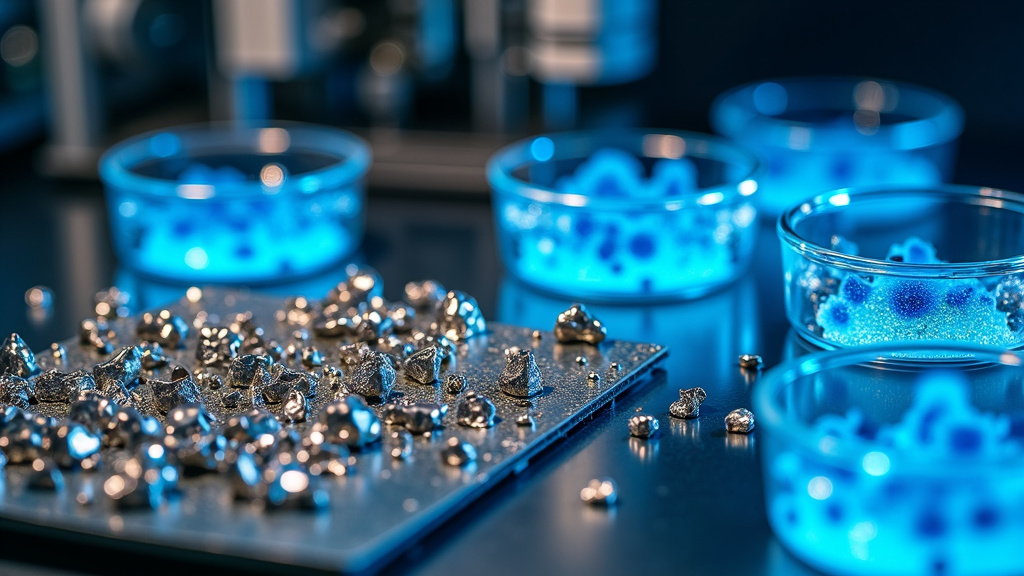

As the demand for rare metals increases due to green technologies, innovative recycling methods are emerging to address this challenge sustainably. Two cutting-edge approaches – fiber-based recovery materials and microbial bio-methods – are transforming how we reclaim these valuable resources from waste streams.

Fiber-Based Recovery Materials: A Game-Changer for Rare Earth Elements

Researchers at the Korea Institute of Science and Technology have developed a fiber-based material for recovering rare earth metals like neodymium and dysprosium. This novel approach offers significant advantages over traditional methods.

The fiber-based material, composed of metal-organic structures and polymer acryl fibers, demonstrates remarkable efficiency. It can adsorb up to 468.60 mg/g of neodymium and 435.13 mg/g of dysprosium – the highest capacities reported worldwide.

Dr. Jae-Woo Choi, lead researcher on the project, explains: “Our high-efficiency rare earth metal recovery material shows excellent results in performance, productivity, economy, and applicability. It has great potential for industrial application through resource recycling.” This innovation could play a crucial role in addressing rare earth supply challenges.

Microbial Bio-Methods: Nature’s Refineries at Work

Another frontier in sustainable rare metal recycling harnesses the unique capabilities of microorganisms. Certain bacteria have evolved mechanisms to detoxify their environment by removing metals from solution, often converting them into nanoparticles.

Researchers at the University of Edinburgh are exploring how these microbial processes can be applied to recover metals from electronic waste and discarded batteries. Their two-step bacterial treatment has achieved impressive results, with removal efficiencies of 96% for manganese and over 90% for nickel and cobalt.

This bio-based approach offers several advantages over conventional methods. As Dr. Louise Horsfall, chair of sustainable biotechnology at the university, notes: “Our disruptive innovations will lead to the development of unique and sustainable new products, derived from wastes and by-products, demonstrating cost-efficient and energy-saving production using novel biomanufacturing technologies.”

Sustainable Solutions for a Circular Economy

Both fiber-based and microbial recycling methods represent significant steps toward a more sustainable, circular economy for rare metals. These approaches not only reduce the environmental impact of metal extraction but also offer potential economic benefits.

As we continue to develop and refine these technologies, they promise to play a crucial role in securing the supply of critical materials for green technologies. By turning waste into valuable resources, innovative recycling methods are paving the way for a more sustainable future.

Challenges and Opportunities in Rare Metal Supply Chains

The global demand for rare metals is increasing rapidly due to their essential role in modern technologies and the transition to clean energy. These elements, often called the ‘vitamins’ of industry, are crucial for everything from smartphones to electric vehicles and wind turbines. However, the journey from mine to market involves complexities beyond logistics.

Geopolitical tensions heavily influence rare metal supply chains. China’s dominance, controlling up to 85-90% of global rare earth element processing, has raised concerns worldwide. This concentration of power leads to fears of potential supply disruptions and their widespread impact on global industries.

Recent events, such as China’s export controls on gallium and germanium—key components in semiconductor manufacturing—highlight the vulnerabilities in our interconnected global economy. How might future geopolitical shifts affect the availability of these essential resources?

Resource Scarcity and Environmental Concerns

Beyond geopolitical issues, resource scarcity is a major concern. While rare metals are not scarce in the Earth’s crust, economically viable deposits are limited. The U.S. Geological Survey’s latest report provides a sobering view of global reserves, particularly for elements like dysprosium and neodymium, crucial for permanent magnets in electric motors.

| Country | Reserves (Million Metric Tons) |

| China | 44 |

| Brazil | 21 |

| India | 6.9 |

| Australia | 5.7 |

| Russia | 3.8 |

| Vietnam | 3.5 |

| United States | 1.9 |

| Greenland | 1.5 |

Moreover, the environmental cost of rare metal extraction is significant. Traditional mining often results in ecological damage, from habitat destruction to toxic byproducts. As global demand rises, how do we balance technological needs with environmental care?

These challenges have spurred innovation and international cooperation. Recycling has emerged as a hopeful solution in this complex landscape. Advanced recycling technologies now recover rare metals from electronic waste with remarkable efficiency.

Innovative Solutions and International Cooperation

Consider the groundbreaking work at the Critical Materials Institute, where researchers are developing new methods to extract rare earth elements from coal ash. This not only provides a new source of these vital materials but also addresses the environmental legacy of coal power generation.

International cooperation is gaining momentum. The Minerals Security Partnership, a coalition of 13 countries including the United States, Japan, and European nations, is working to develop diverse, sustainable supply chains for critical minerals. This collaborative approach could lead to more resilient global networks.

But questions remain: Can these initiatives scale quickly enough to meet growing demand? How might emerging technologies like deep-sea or asteroid mining reshape the rare metals landscape?

At this critical juncture, it’s clear that the challenges in rare metal supply chains are complex. Yet, they also offer opportunities for innovation, cooperation, and reimagining how we source and use these vital resources. The solutions we develop today will shape our technological, economic, and environmental future for decades.

The Role of High-Efficiency Recycling in a Sustainable Future

High-efficiency recycling is more than waste management—it’s a driving force behind sustainability and economic transformation, leading us toward a circular economy.

Innovative recycling techniques, especially in rare metal recovery, minimize waste, conserve resources, and reduce environmental impact. Businesses that adopt these solutions align with sustainability goals while strengthening the global economy.

By shifting from a take-make-dispose model to a circular system, we extend material lifespans, lower energy consumption, and cut carbon emissions. This transition is critical in the fight against climate change and resource depletion.

Success requires collective action—from individuals choosing recycled products to businesses investing in sustainable solutions. Each step toward high-efficiency recycling is a step toward a greener, more resilient future.

With the right technologies and commitment, economic growth and environmental responsibility can thrive together. Let’s embrace these practices and build a cleaner, more sustainable world.

To be part of this transformation, Okon Recycling provides cutting-edge recycling solutions that maximize efficiency while minimizing waste. Contact Okon Recycling at 214-717-4083 to learn more about sustainable recycling practices and how your business can contribute to a circular economy. Together, we can shape a cleaner future.