5901 Botham Jean Blvd, Dallas, TX 75215

Recycled Copper Applications: A Sustainable Future

March 23, 2025Recycling copper can save up to 85% of the energy needed to produce copper from virgin ore. This important statistic highlights the critical role recycled copper plays in creating a more sustainable future for our planet.

Copper, a versatile reddish-brown metal used in everything from electrical wiring to plumbing fixtures, has been essential to human development for millennia. Its significance continues to grow, especially in renewable energy systems, electric vehicles, and other technologies driving the green revolution. However, the rising demand for copper presents a challenge: how can we meet this demand without depleting Earth’s finite resources?

Recycled copper applications offer a solution. Through urban mining and advanced recycling technologies, we can give new life to copper products at the end of their initial use. This circular approach not only reduces the need for environmentally harmful mining practices but also cuts carbon emissions and conserves water resources. According to the International Copper Association, recycling copper can require up to 90% less energy than primary copper production.

As we explore the world of recycled copper applications, we’ll see how this sustainable alternative is transforming industries.

Common Applications of Recycled Copper

Recycled copper plays a crucial role in numerous industries, highlighting its versatility and sustainability. From powering devices to constructing buildings, this metal finds its way into countless applications, reducing the need for virgin copper extraction. Let’s explore some common and innovative uses of recycled copper across various sectors.

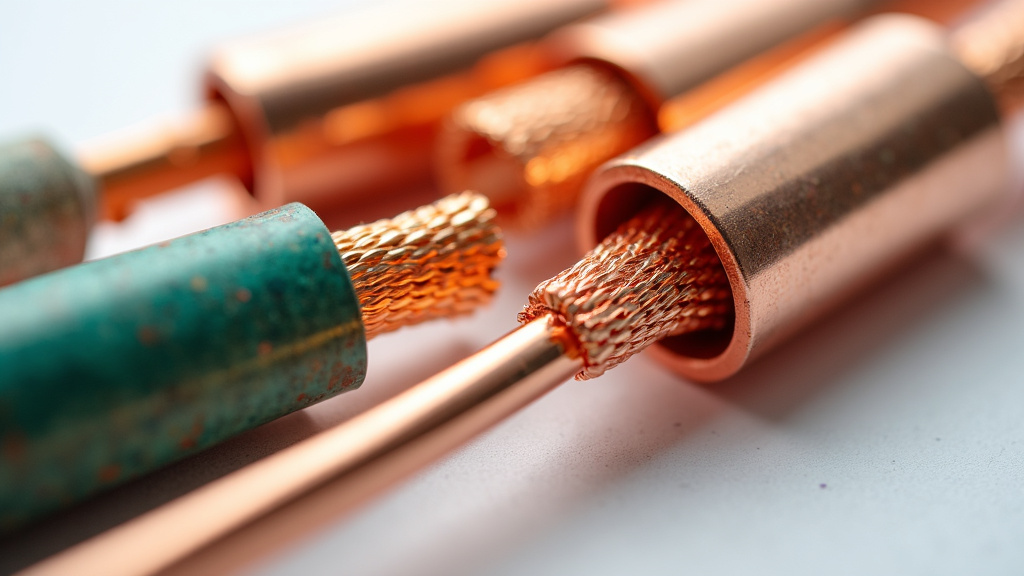

Electronics: The Heart of Our Digital World

In electronics, recycled copper is essential. Its excellent conductivity makes it a prime choice for creating efficient and reliable products. The smartphone in your pocket likely contains recycled copper in its circuitry.

Printed circuit boards (PCBs), the backbone of nearly all electronic devices, rely heavily on copper traces to connect components. Using recycled copper in PCBs significantly reduces the environmental impact of electronics production. Experts estimate that up to 50% of the copper in some PCBs comes from recycled sources.

It’s not just smartphones and computers. Kitchen appliances, from refrigerators to coffee makers, also benefit from recycled copper. The motor windings in these devices incorporate recycled copper, ensuring efficient operation while promoting sustainability.

Construction: Building a Sustainable Future

The construction industry is a major consumer of recycled copper, utilizing its durability and corrosion resistance. One visible application is in plumbing systems. Copper pipes delivering clean water may be made from recycled materials, showcasing copper’s infinite recyclability without loss of performance.

Roofing is another area where recycled copper excels. Copper roofs, known for their distinctive green patina and longevity, can last over a century. Many architects and builders opt for recycled copper, marrying aesthetic appeal with environmental responsibility.

Even in hidden parts of buildings, recycled copper plays a crucial role. Electrical wiring, HVAC systems, and energy-efficient heat exchangers benefit from recycled copper, contributing to more sustainable construction practices.

Transportation: Driving Innovation and Efficiency

The transportation sector increasingly turns to recycled copper to improve vehicle performance and reduce environmental impact. In conventional vehicles, recycled copper finds its way into components from electrical systems to radiators.

In electric vehicles (EVs), recycled copper truly takes center stage. EVs require significantly more copper than fossil-fuel vehicles—up to four times as much. This demand makes recycled copper critical in the automotive industry.

From high-powered motors to extensive wiring harnesses, recycled copper helps make EVs more sustainable from production to operation. Even the charging infrastructure relies heavily on copper, with each station containing substantial amounts of the metal.

Renewable Energy: Powering a Cleaner Future

An exciting application of recycled copper lies in the renewable energy sector. As the world transitions to cleaner energy sources, demand for copper in solar panels, wind turbines, and energy storage systems has skyrocketed.

Solar photovoltaic systems depend on copper for wiring and inverters. The efficiency of these systems in converting sunlight to electricity is partly due to copper’s superior conductivity. Using recycled copper, solar panel manufacturers can further reduce the carbon footprint of this technology.

Wind turbines are major consumers of copper. From generator windings to cabling systems, a single turbine can contain several tons of copper. Using recycled copper in these applications conserves resources and enhances the sustainability of wind energy.

As we strive for a sustainable future, recycled copper’s role in these applications becomes increasingly crucial. By choosing products and supporting industries that utilize recycled copper, we contribute to a more circular and environmentally friendly economy. The versatility of recycled copper truly makes it a hero in our quest for sustainability across multiple sectors.

| Industry | Application | Benefits |

|---|---|---|

| Electronics | Printed Circuit Boards (PCBs) | Reduces environmental impact, up to 50% recycled copper used |

| Construction | Plumbing, Roofing | Durability, corrosion resistance, infinite recyclability |

| Transportation | Electric Vehicles (EVs) | Supports sustainability, up to four times more copper than conventional vehicles |

| Renewable Energy | Solar Panels, Wind Turbines | Enhances efficiency and sustainability, uses several tons of copper |

The Copper Recycling Process

Copper recycling is a remarkable journey that transforms discarded materials into valuable resources, playing a crucial role in sustainable resource management. This process conserves our planet’s finite copper reserves and significantly reduces energy consumption and environmental impact compared to mining new copper.

Here’s an overview of the copper recycling process, highlighting how this metal gets a new lease on life:

1. Collection and Sorting

The recycling journey begins with the collection of copper-containing items from various sources, including old electrical wires, plumbing pipes, and discarded electronic devices. According to CJD E-Cycling experts, construction sites are rich sources of recyclable copper, often yielding materials like copper wire, fittings, and valves.

Once collected, the copper is meticulously sorted based on its grade and purity, a crucial step that determines the recycling method and the quality of the recycled copper produced.

2. Preprocessing and Shredding

After sorting, the copper-containing materials undergo preprocessing, often involving the removal of non-copper components, such as plastic insulation from wires. The cleaned copper is then fed into powerful shredders that break it down into small, manageable pieces.

This shredding step increases the surface area of the copper, making the subsequent melting process more efficient. It’s a noisy but essential part of the recycling journey!

3. Melting and Purification

The shredded copper is melted in large furnaces at temperatures exceeding 2,000°F (1,093°C). This intense heat transforms the solid copper into a molten state, allowing for easier purification. During this stage, any remaining impurities rise to the surface as slag and are skimmed off.

Research from the World Resources Institute shows that recycling copper uses up to 85% less energy than mining and refining new copper. That’s a significant energy saving!

4. Casting and Shaping

Once purified, the molten copper is cast into various forms, depending on its intended use. Common shapes include ingots, bars, or rolls, which are then cooled and solidified, ready for the next stage of manufacturing.

At this point, the recycled copper is indistinguishable from newly mined copper in terms of quality and performance. It’s a testament to the efficiency of the recycling process!

5. Quality Control and Distribution

Before leaving the recycling facility, the recycled copper undergoes rigorous quality control checks to ensure it meets industry standards for purity and performance. Once approved, it’s distributed to manufacturers who will transform it into new products, completing the recycling loop.

From start to finish, the copper recycling process showcases human ingenuity and our commitment to sustainability. By giving copper a second (or third, or hundredth) life, we are not just conserving resources but building a more circular and sustainable future for generations to come.

Innovations in Recycled Copper Applications

The realm of recycled copper is experiencing significant advancements, with innovations driving more sustainable and efficient uses of this adaptable metal. As industries face the challenge of increasing copper demand while minimizing environmental impact, recycling has become a key solution. Here are some of the most exciting developments in this evolving field.

Advanced Alloy Development

One promising area of innovation is the creation of new copper alloys using recycled materials. Researchers are expanding the boundaries of metallurgy to develop alloys with enhanced properties while maximizing recycled copper use. For example, scientists at the Copper Development Association are working on alloys that combine recycled copper with other metals to improve strength, conductivity, and corrosion resistance.

These advanced alloys are applied in various sectors, from electronics to automotive manufacturing. By refining composition and processing techniques, engineers can tailor recycled copper alloys to meet specific performance requirements, often matching or exceeding the capabilities of alloys made from virgin materials.

The implications of this research are extensive. As more industries adopt these innovative alloys, the demand for recycled copper is likely to increase, further encouraging recycling efforts and reducing reliance on primary copper production.

Nano-technologies and Recycled Copper

Another promising frontier in recycled copper applications is the integration of nanotechnology. Scientists are exploring how to leverage the unique properties of materials at the nanoscale to enhance recycled copper’s performance. One particularly promising area is the development of copper nanoparticles and nanocomposites.

Researchers at leading institutions are studying how copper nanoparticles from recycled sources can be used to create advanced materials with superior electrical and thermal conductivity. These materials have potential applications in next-generation electronics, energy storage devices, and medical technologies.

Moreover, nanotechnology is also being applied to improve the recycling process itself. Advanced separation techniques using nanomaterials are being developed to extract copper more efficiently from complex waste streams, potentially increasing the yield and quality of recycled copper.

Future Trends in Recycled Copper Applications

Several trends are likely to shape the future of recycled copper applications:

- Increased focus on ‘urban mining’: As the world’s stock of copper-containing products grows, there will be a greater emphasis on recovering copper from end-of-life electronics, buildings, and infrastructure. This trend aligns with circular economy principles and could significantly reduce the need for primary copper production.

- Integration with renewable energy systems: Recycled copper is expected to play a crucial role in developing more efficient solar panels, wind turbines, and energy storage solutions. As the World Resources Institute notes, copper is essential for the clean energy transition, and recycled sources will be vital in meeting this demand sustainably.

- Advancements in 3D printing: The ability to 3D print complex components using recycled copper alloys is an area of active research. This technology could revolutionize manufacturing processes, allowing for more efficient use of materials and customized production of copper-based parts.

As these innovations continue to unfold, the future of recycled copper looks promising. By harnessing advanced alloys, nanotechnology, and emerging manufacturing techniques, we are discovering new ways to use this ancient metal while contributing to a more sustainable and resource-efficient world.

The ongoing research and development in recycled copper applications highlight human ingenuity and our capacity to adapt to environmental challenges. These innovations will undoubtedly play a crucial role in shaping a more sustainable and technologically advanced future.

How Okon Recycling Can Help with Recycled Copper Applications

With over a century of experience in metal recycling, Okon Recycling leads in sustainable copper recycling practices. Their expertise in procuring, processing, and distributing recycled copper makes them vital in supporting innovative applications across industries. Explore how Okon’s commitment to sustainability shapes the future of copper recycling.

Expertise in Copper Procurement

Okon Recycling’s long-standing presence in the industry has enabled them to develop a robust network for sourcing recycled copper. Their procurement strategies extend beyond collecting scrap; they engage with industries to recover copper from end-of-life products, contributing to urban mining. This approach ensures a steady supply of recyclable copper and significantly reduces the environmental impact of primary copper production.

By sourcing from construction debris, electronic waste, and industrial byproducts, Okon maximizes copper recovery. Their proactive procurement methods help divert copper from landfills, aligning with global sustainability goals and circular economy principles.

Okon’s expertise includes identifying and segregating different grades of copper scrap, ensuring each type is directed to the most suitable recycling process. This meticulous approach maximizes the value and quality of recycled copper for various applications.

Advanced Processing Techniques

The core of Okon Recycling’s operations lies in their state-of-the-art processing facilities. Utilizing cutting-edge technologies, they refine copper recycling processes to achieve high purity and efficiency. Their advanced sorting systems, including optical and electromagnetic separation techniques, ensure effective isolation of copper from other materials.

Okon’s commitment to innovation is evident in their continuous investment in upgrading recycling infrastructure. They employ sophisticated smelting and refining processes that produce high-quality recycled copper while minimizing energy consumption and emissions. This dedication to sustainable practices sets a benchmark for the industry, showing that environmental responsibility and economic viability can coexist.

Moreover, Okon’s processing capabilities extend to handling complex copper alloys and composite materials. Their expertise opens new possibilities for recycling copper from sources previously considered challenging or uneconomical to process.

Strategic Distribution and Market Integration

Okon Recycling’s role extends beyond processing; they are pivotal in distributing recycled copper to various sectors. Their understanding of market demands and quality requirements allows them to supply recycled copper that meets specific industry needs. From construction and electronics to renewable energy systems, Okon ensures recycled copper is integrated into diverse applications.

Their strategic partnerships with manufacturers and industry leaders facilitate the integration of recycled copper into new products. By working closely with end-users, Okon helps close the loop of the copper lifecycle, promoting a circular economy model that reduces reliance on primary copper resources.

Okon’s distribution network also stabilizes the supply of recycled copper. This stability is essential for industries incorporating sustainable materials into their production processes, providing confidence in relying on recycled copper for long-term needs.

Contributions to Sustainable Industry Practices

Okon Recycling’s century-long commitment to metal recycling positions them as a leader in promoting sustainable industry practices. By facilitating the use of recycled copper, they help industries reduce their carbon footprint and conserve natural resources. The energy savings from copper recycling are substantial, with recycled copper requiring up to 85% less energy than primary copper extraction.

Moreover, Okon’s advocacy for recycled copper usage goes beyond supply. They actively educate industries on the benefits and applications of recycled copper, fostering a culture of sustainability across the supply chain. This educational initiative helps break down barriers and misconceptions about recycled materials, encouraging more businesses to embrace sustainable practices.

Through their efforts, Okon Recycling is not just supplying recycled copper; they are catalyzing a shift towards more sustainable and responsible resource utilization globally. Their expertise and commitment to quality ensure that recycled copper is seen not as a compromise but as a preferable choice for innovative and environmentally conscious applications.

| Application | Role of Recycled Copper | Benefits |

|---|---|---|

| Electronics | Used in printed circuit boards and motor windings | Reduces environmental impact, maintains efficiency |

| Construction | Utilized in plumbing, roofing, and electrical wiring | Durable, corrosion-resistant, sustainable |

| Transportation | Incorporated in electric vehicles and conventional vehicles | Improves performance, reduces environmental impact |

| Renewable Energy | Used in solar panels and wind turbines | Enhances efficiency, reduces carbon footprint |

Embracing a Sustainable Future with Recycled Copper

Recycled copper is not merely a trend; it is a transformative element in our sustainability efforts. By choosing recycled copper, we conserve valuable natural resources, reduce energy consumption by up to 85%, and significantly lower carbon emissions. This ‘urban mining’ approach not only protects ecosystems from the impact of traditional copper extraction but also revitalizes materials that might otherwise end up in landfills.

The influence of recycled copper goes beyond environmental advantages. It plays a crucial role in promoting a circular economy, creating jobs in the recycling sector, and ensuring a stable supply of this essential metal for future generations. As the demand for copper in renewable energy technologies, electric vehicles, and smart infrastructure grows, recycled copper provides a sustainable solution to meet these needs without compromising our planet’s health.

Now is the time for action. Whether you are a homeowner planning a renovation, a business owner aiming to enhance sustainability practices, or an industry leader seeking innovative solutions, consider the powerful impact of incorporating recycled copper into your projects. Every choice to use recycled copper is a step towards a cleaner, more efficient world.

Ready to make a difference? Okon Recycling leads this sustainable movement, offering expertise and solutions to help you leverage the power of recycled copper.

Contact Okon Recycling at 214-717-4083 to learn how you can contribute to a more sustainable future while benefiting from the exceptional quality and versatility of recycled copper. Together, we can build a world where sustainability and innovation coexist, powered by the enduring strength of recycled copper.