5901 Botham Jean Blvd, Dallas, TX 75215

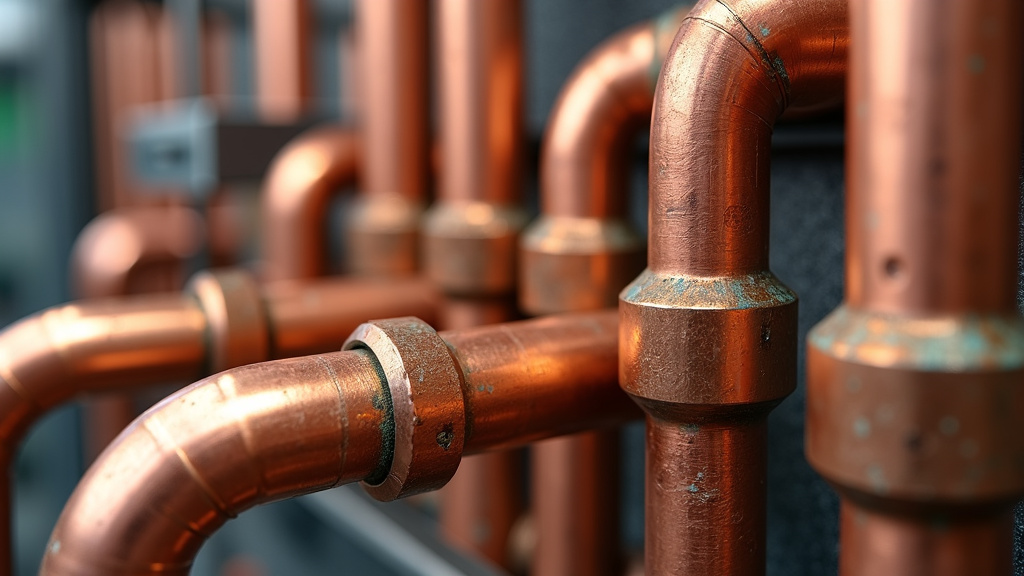

Understanding the Corrosion Resistance of Copper

March 21, 2025Did you know that copper roofing corrodes at rates of less than 0.015 inches (0.4mm) over 200 years? This remarkable longevity highlights copper’s exceptional corrosion resistance, making it invaluable across diverse industries. From towering skyscrapers to intricate electronic components, copper’s ability to withstand environmental degradation offers a sustainable solution for our modern world.

Copper’s corrosion resistance is due to its unique chemical properties. When exposed to the atmosphere, copper forms a protective layer called patina – a complex film of copper oxides, sulfides, and carbonates. This natural shield preserves the underlying metal and imparts the iconic blue-green hue seen on landmarks like the Statue of Liberty. Unlike iron oxide (rust), which accelerates corrosion, copper’s patina acts as a barrier, slowing further oxidation and extending the material’s lifespan.

The implications of copper’s corrosion resistance go beyond aesthetics. In the construction industry, copper roofing, flashing, and architectural elements withstand decades of harsh weather with minimal maintenance. For the electronics sector, copper’s durability ensures the longevity of critical components in circuit boards and wiring systems. Even in marine environments, where corrosion is a constant threat, copper-nickel alloys demonstrate remarkable resilience against saltwater degradation.

The Science Behind Copper’s Corrosion Resistance

Copper’s ability to withstand corrosion is rooted in its unique chemical composition. Imagine copper as a self-healing superhero among metals.

When copper encounters air or moisture, it forms a protective shield called a patina, safeguarding the copper beneath from further damage.

How does this work? When copper is exposed to oxygen, it undergoes a chemical reaction, forming a thin layer of copper oxide on the surface, akin to a coat of armor.

The Formation of Copper’s Protective Layer

Over time, this initial layer reacts with carbon dioxide and sulfur compounds in the air, upgrading its defenses layer by layer. The result is a stable green-blue coating known as patina.

This patina is a highly effective barrier against corrosion. Unlike rust on iron, which flakes off, copper’s patina remains intact, protecting the metal underneath.

The beauty of this process is its self-sustaining nature. Copper’s corrosion resistance is particularly strong in non-oxidizing environments, meaning that once the patina forms, it continues to shield the copper.

The Long-Term Benefits of Copper’s Corrosion Resistance

This property translates into impressive durability. Copper roofs can last for centuries. The Statue of Liberty, with its iconic green patina, is a testament to copper’s longevity.

Copper’s corrosion resistance also has practical implications. In plumbing, copper pipes resist mineral buildup and bacterial growth, ensuring clean water flow for decades.

In marine environments, where salt water quickly corrodes many metals, copper and its alloys stand strong, making it invaluable in shipbuilding and coastal construction.

Copper: Nature’s Corrosion-Fighting Champion

Understanding copper’s corrosion resistance highlights why it’s been a go-to metal for thousands of years. From ancient Egyptian water carriers to modern electrical wiring, copper’s durability has made it indispensable.

Next time you see a green copper roof or handle an old penny, remember you’re witnessing a sophisticated chemical defense system. It’s not just a metal; it’s nature’s corrosion-fighting champion.

This property ensures that copper-based products, from decorative items to infrastructure components, stand the test of time. In a world where sustainability is crucial, copper’s durability makes it a smart choice for long-lasting, low-maintenance applications.

Environmental Benefits of Copper’s Corrosion Resistance

Copper’s remarkable corrosion resistance is not just a testament to its durability—it’s a key factor in promoting a sustainable future. This property plays a crucial role in reducing waste and minimizing environmental impact, aligning with circular economy principles.

Consider the numbers: According to the International Copper Association, about two-thirds of the 550 million tonnes of copper produced since 1900 are still in use today. This statistic highlights copper’s longevity and its potential to significantly reduce the need for replacements.

What does this mean for our environment? It’s transformative. The extended lifespan of copper products results in less waste. Fewer replacements mean fewer resources extracted, less energy consumed in manufacturing, and a significant reduction in landfill material.

Copper’s Role in the Circular Economy

Copper’s corrosion resistance aligns perfectly with circular economy goals of eliminating waste and maximizing resource efficiency. Copper supports these goals through its longevity and recyclability.

Copper’s contribution extends beyond its lifespan. It’s 100% recyclable without performance loss, making it exemplary for sustainable material use. When copper products reach the end of their lives, they can be fully recycled and reintroduced into production.

The environmental benefits are substantial. Recycling copper requires up to 85% less energy than primary production, significantly reducing the carbon footprint. It’s a win-win: we continue using this versatile metal while reducing environmental impact.

Quantifying the Environmental Impact

The waste reduction from copper’s corrosion resistance is remarkable. In construction, copper plumbing can last over 50 years, and copper roofing can endure over a century, translating into significant waste reduction.

Moreover, copper’s durability contributes to energy savings throughout its lifecycle. Electrical systems with copper emit between 100 and 7,500 fewer tonnes of CO2 over their lifetimes compared to less efficient materials. This emission reduction results from copper’s superior conductivity and corrosion resistance, minimizing energy losses and replacement needs.

The environmental benefits extend beyond waste reduction and energy savings. By reducing the need for frequent replacements, copper helps conserve resources such as water used in mining and manufacturing, and fuel consumed in transportation and installation.

Sustainable Development and Copper

Copper’s corrosion resistance benefits not only individual products or industries but also broader sustainable development goals. By reducing waste, conserving resources, and minimizing environmental impact, copper plays a crucial role in creating a sustainable future.

Copper’s longevity and recyclability support the United Nations Sustainable Development Goal 12, which aims for sustainable consumption and production patterns. Choosing corrosion-resistant copper promotes responsible resource use and reduces our ecological footprint.

In conclusion, copper’s corrosion resistance is more than just a material property—it’s a vital tool in our sustainability efforts. As we face environmental challenges, copper’s durability offers a clear example of how smart material choices can lead to significant environmental benefits. It reminds us that impactful solutions often stand the test of time.

How Okon Recycling Can Help with Corrosion Resistance of Copper

Copper’s exceptional corrosion resistance makes it a prized material across numerous industries. Okon Recycling, a leader in metal recycling, plays a vital role in harnessing this valuable property through its advanced copper recycling processes. By effectively collecting, processing, and reintegrating copper into the supply chain, Okon Recycling not only supports a sustainable circular economy but also helps businesses maximize the benefits of this durable metal.

The corrosion resistance of copper is due to its unique ability to form a protective patina when exposed to the environment. This natural barrier shields the underlying metal from further degradation, extending its lifespan and reducing maintenance costs. Okon’s specialty metal processing plants are designed to preserve these beneficial properties during the recycling process, ensuring that the reclaimed copper retains its full corrosion-resistant potential.

One of the key ways Okon Recycling supports the optimization of corrosion-resistant copper is through its state-of-the-art sorting and purification techniques. These methods allow for the separation of copper from other metals and contaminants, resulting in high-quality recycled copper that meets or exceeds industry standards. This purity is crucial for maintaining the metal’s corrosion resistance in demanding applications such as marine environments, chemical processing facilities, and architectural uses.

Sustainable Practices in Copper Recycling

Okon Recycling’s commitment to sustainability goes beyond simply reclaiming copper. The company’s processes are designed to minimize energy consumption and reduce environmental impact. Recycling copper requires up to 85% less energy than primary production, significantly lowering carbon emissions associated with copper use. This energy efficiency not only benefits the environment but also translates to cost savings for businesses that choose recycled copper for their corrosion-resistant applications.

Moreover, Okon’s expertise in copper recycling supports the broader goals of the circular economy. By keeping copper in use for longer periods and reducing the need for virgin material extraction, Okon helps conserve natural resources and reduce the environmental footprint of copper-based products. This aligns with the growing emphasis on sustainability in industries ranging from construction to electronics manufacturing.

The company’s advanced recycling technologies also allow for the recovery of copper from complex end-of-life products, such as electronic waste. This capability is increasingly important as the demand for copper in high-tech applications continues to grow. By efficiently extracting copper from these sources, Okon ensures that valuable corrosion-resistant material is not lost to landfills but remains available for future use.

Optimizing Corrosion Resistance for Industries

Okon Recycling’s services extend beyond mere material recovery. The company works closely with businesses to understand their specific needs for corrosion-resistant copper. This collaboration allows Okon to tailor its recycling processes to produce copper that meets exact specifications, whether for electrical conductivity, thermal performance, or aesthetic requirements in architectural applications.

For industries such as shipbuilding and offshore energy, where corrosion resistance is paramount, Okon’s recycled copper offers a reliable and sustainable solution. The company’s ability to consistently deliver high-quality recycled copper helps these industries maintain the integrity of their equipment and structures in harsh marine environments, reducing maintenance costs and extending operational lifespans.

In the construction sector, Okon’s recycled copper supports the creation of durable, low-maintenance building materials. From roofing and cladding to plumbing systems, recycled copper’s corrosion resistance ensures longevity and reduces the need for frequent replacements. This durability contributes to more sustainable building practices and lower lifetime costs for property owners.

Supporting Innovation in Corrosion-Resistant Applications

Okon Recycling’s commitment to quality and innovation positions it as a valuable partner for businesses developing new corrosion-resistant applications. As industries seek to push the boundaries of material performance, Okon’s expertise in producing high-grade recycled copper enables the creation of advanced alloys and composites that offer enhanced corrosion protection.

Furthermore, Okon’s involvement in the circular economy for copper encourages a more holistic approach to product design. By demonstrating the viability and benefits of recycled copper, Okon inspires manufacturers to consider end-of-life recyclability in their product development processes. This forward-thinking approach not only improves the sustainability of copper-based products but also ensures a steady supply of high-quality, corrosion-resistant material for future applications.

In conclusion, Okon Recycling’s sophisticated copper recycling services play a crucial role in maximizing the benefits of copper’s corrosion resistance. By ensuring the efficient collection, processing, and reintegration of copper into the supply chain, Okon not only contributes to a more sustainable circular economy but also empowers industries to fully leverage the durability and longevity of this remarkable metal. As businesses increasingly prioritize sustainability and material performance, Okon Recycling stands ready to support their needs with high-quality, corrosion-resistant recycled copper.

Embracing Copper’s Corrosion Resistance for a Sustainable Future

Copper’s remarkable corrosion resistance is more than a scientific curiosity—it’s a crucial ally in sustainability. This enduring metal exemplifies nature’s ingenuity and human innovation, offering paths to durable, resource-efficient solutions across industries.

From construction to electronics, copper’s longevity leads to reduced waste and lower replacement rates. Every copper pipe that doesn’t need replacing, every electrical component that outlasts alternatives—these are victories against resource depletion and environmental harm.

The benefits extend beyond durability. Copper’s recyclability is extraordinary. According to the Copper Alliance, about 80% of all copper ever mined is still in use today, highlighting the metal’s role in a circular economy.

In building a sustainable future, partnering with recycling experts is crucial. This is where Okon Recycling steps in, offering businesses a chance to close the loop on copper usage. By leveraging Okon’s century of experience and advanced recycling technologies, companies can ensure their copper scrap finds new life, enhancing their sustainability credentials.

The choice is clear: by embracing copper’s corrosion resistance and partnering with recycling leaders like Okon Recycling, businesses aren’t just making a smart material choice—they’re investing in a sustainable, resource-efficient future. Ready to make an impact? Contact Okon Recycling at 214-717-4083 to discover how your copper waste can become a cornerstone of your sustainability strategy.