5901 Botham Jean Blvd, Dallas, TX 75215

Recycling Commercial Air Conditioning Systems: An Overview

January 31, 2025Did you know that over 9 million commercial air conditioners reach the end of their lifespan each year in the United States alone? This represents a significant amount of potential waste. But what if we could turn this challenge into an opportunity for sustainability?

Recycling commercial air conditioning systems isn’t as simple as tossing an empty soda can into a blue bin. These complex machines contain valuable metals and intricate components, each requiring specialized handling and processing. It’s a puzzle that demands expertise, innovation, and a commitment to environmental stewardship.

Why should we care about recycling these bulky systems? The answer lies in the intersection of environmental responsibility and economic opportunity. By properly recycling commercial AC units, we can:

- Conserve natural resources by recovering metals like copper, aluminum, and steel

- Reduce landfill waste and associated greenhouse gas emissions

- Create jobs in the recycling and remanufacturing sectors

- Comply with increasingly stringent environmental regulations

How do we tackle this complex challenge? This is where companies like Okon Recycling come into play. With over a century of experience in metal recycling, Okon exemplifies the industry’s evolution in handling non-traditional and large-scale materials such as air conditioning units.

As we explore the world of commercial AC recycling, we’ll examine the intricate processes involved, the environmental impact, and the innovative solutions shaping the future of sustainable waste management. Are you ready to discover how your old AC unit could be transformed into something entirely new?

Challenges in Recycling Commercial HVAC Scrap

Commercial HVAC systems, the unsung heroes of climate control in our offices and shopping centers, present unique recycling challenges. These giants of temperature regulation are not your average household appliances, and their end-of-life journey is complex.

The sheer size and complexity of commercial HVAC units make them difficult to recycle. Picture a system that could easily dwarf your car, composed of an intricate maze of metals, plastics, and electronic components. It’s not something you can simply toss into a recycling bin.

But size isn’t the only hurdle. The real issue is the refrigerant these systems contain. These chemical coolants, while essential for the HVAC’s function, are environmental hazards if not handled properly. According to the Environmental Protection Agency, some refrigerants can have a global warming potential thousands of times greater than carbon dioxide.

The Environmental Impact

Improper disposal of HVAC systems isn’t just a matter of wasted resources; it’s a significant environmental hazard. When these systems end up in landfills, they leak harmful substances into the soil and groundwater, creating a toxic legacy that can last for generations.

The refrigerants, if released into the atmosphere, contribute to ozone depletion and accelerate global warming. It’s sobering that a single poorly handled HVAC unit could undo years of environmental conservation efforts.

But it’s not all negative. Responsible recycling practices can turn this potential environmental disaster into a sustainability success story. This is where companies like Okon Recycling come into play, pioneering innovative techniques to tackle these recycling challenges.

Innovative Solutions

Okon Recycling, for instance, has developed a multi-step process to dismantle and recycle commercial HVAC systems safely. Their approach begins with a careful assessment of each unit, identifying hazardous components and planning the most efficient recycling route.

One of the most critical steps is the safe extraction and containment of refrigerants. Specialized equipment is used to capture these gases, preventing their escape into the atmosphere. The recovered refrigerants can then be purified and reused, or safely destroyed if they’re obsolete or contaminated.

But the innovation doesn’t stop there. Advanced sorting technologies are employed to separate the various metals, plastics, and electronic components. This meticulous sorting ensures that each material can be recycled to its highest potential, maximizing resource recovery and minimizing waste.

Every ton of recycled HVAC material represents not just recovered resources but a significant reduction in greenhouse gas emissions and energy consumption compared to producing new materials.

Environmental Protection Agency

The recycling process itself is a marvel of modern engineering. Powerful shredders reduce bulky components to manageable sizes, while magnetic separators and eddy current systems sort ferrous and non-ferrous metals with incredible precision. Even the plastics are given new life, transformed into raw materials for various industries.

The Road Ahead

As impressive as these recycling techniques are, the challenge of HVAC recycling is far from solved. The industry continues to evolve, with new refrigerants and materials constantly entering the market. This means recycling methods must adapt and improve continuously.

Education and awareness also play a crucial role. Many building owners and facilities managers are unaware of the importance of proper HVAC disposal. Spreading knowledge about the environmental impact of improper disposal and the benefits of recycling is vital for increasing participation in responsible recycling programs.

The future of HVAC recycling lies in collaboration between manufacturers, recyclers, and policymakers. By working together, we can design systems that are not only efficient in operation but also in their end-of-life recycling. This ‘circular economy’ approach could revolutionize the industry, turning today’s cooling towers into tomorrow’s resources.

As we face the growing challenges of climate change and resource scarcity, the importance of responsible HVAC recycling cannot be overstated. It’s a complex puzzle, but with innovative solutions and a commitment to sustainability, we can turn these challenges into opportunities for a greener, more sustainable future.

| Stage | Description |

| Collection | Gathering of old or discarded units by contractors or recycling centers. |

| Refrigerant Recovery | Safe extraction and storage of refrigerants by certified professionals. |

| Disassembly | Separation of components like metals and plastics for recycling. |

| Material Processing | Reforming metals and recycling plastics according to their properties. |

| Responsible Disposal | Disposal of non-recyclable materials following environmental guidelines. |

| Reuse and Repurposing | Refurbishing components for use in other applications. |

Innovative Techniques in Recycling Large-Scale Materials

The recycling industry is experiencing a technological revolution, with groundbreaking solutions reshaping how we process and recycle complex materials. Okon Recycling, a leader in the field, is at the forefront of this transformation, utilizing advanced techniques to manage large-scale recyclables like air conditioning units and magnets. These innovations are not just improving efficiency; they are redefining our approach to waste management.

Advancements in Air Conditioner Recycling

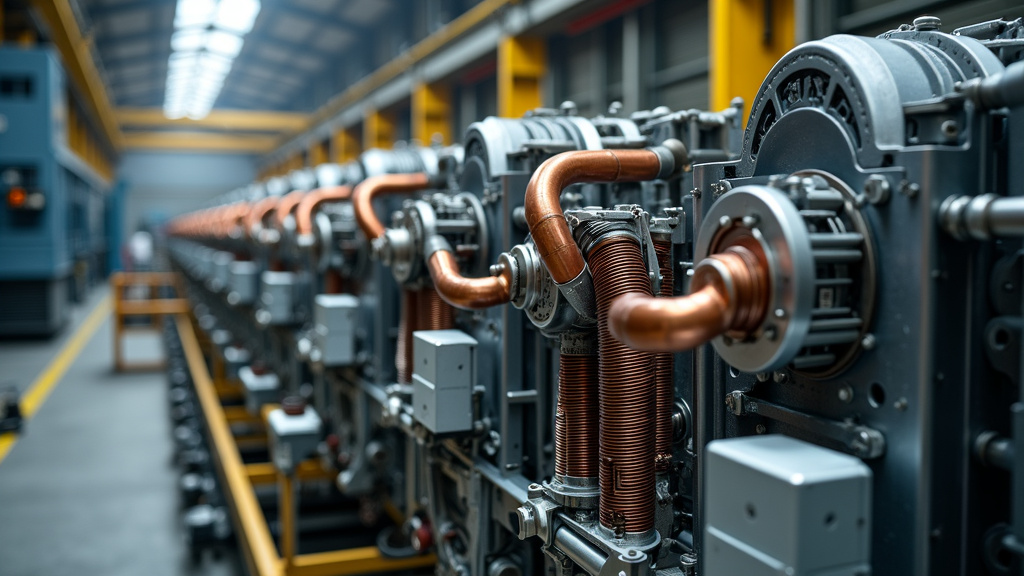

Air conditioning units pose a unique challenge in recycling due to their size and complex composition. Okon Recycling has developed a sophisticated process to tackle this challenge directly. Their innovative system includes a mechanical unit for precisely cutting open the casing, followed by a rotor removal machine that expertly extracts the motor’s rotor.

One of the most remarkable aspects of this process is the demagnetizer, which operates at room temperature using resonance damping demagnetization. This technology allows for safe and efficient handling of the powerful magnets found in AC compressors. The final step involves a magnet removal machine with a drop impact mechanism, ensuring complete separation of valuable materials.

As Kenji Baba, Dr. Eng. from Hitachi, explains: The energy-efficient compressors used in air conditioners contain rare-earth magnets. We’ve developed a machine that damps the strong magnetic field and uses a mechanical process to separate and recover the magnets efficiently.

Magnet Recycling: A Game-Changer in Resource Recovery

Magnets, particularly those containing rare earth elements, are another focus of Okon Recycling’s innovative techniques. The company has implemented a pyrolysis process that breaks down materials at high temperatures in an oxygen-free environment. This method is particularly effective for recycling permanent magnets, electromagnets, and even superconducting MRI magnets.

The pyrolysis technique offers several key advantages:

- It produces valuable byproducts like bio-oil and syngas

- It achieves a 70% reduction in carbon emissions compared to incineration

- It allows for zero waste to landfill

- It enables resource recovery from previously unrecyclable materials

Yuzo Hiroshige, an expert in the field, notes: The scalability of pyrolysis technology makes it suitable for both large industrial operations and smaller community-based recycling facilities, offering flexible solutions for diverse waste management needs.

| Advantage | Description |

| Valuable Byproducts | Produces bio-oil and syngas |

| Carbon Emissions | 70% reduction compared to incineration |

| Zero Waste | Allows for zero waste to landfill |

| Resource Recovery | Enables recovery from previously unrecyclable materials |

Blockchain Technology: Ensuring Transparency in Recycling

Okon Recycling is also leveraging blockchain technology to enhance transparency and traceability in their recycling processes. This decentralized digital ledger system creates an immutable record of materials from collection to final disposal or recycling. It allows for real-time tracking of waste materials throughout their lifecycle, preventing fraudulent reporting and ensuring data accuracy.

The integration of blockchain enables waste producers to verify proper disposal methods, while recyclers can authenticate material sources. This technology creates a digital passport for waste materials, recording crucial data points such as collection time and location, material composition, processing methods, and environmental impact metrics.

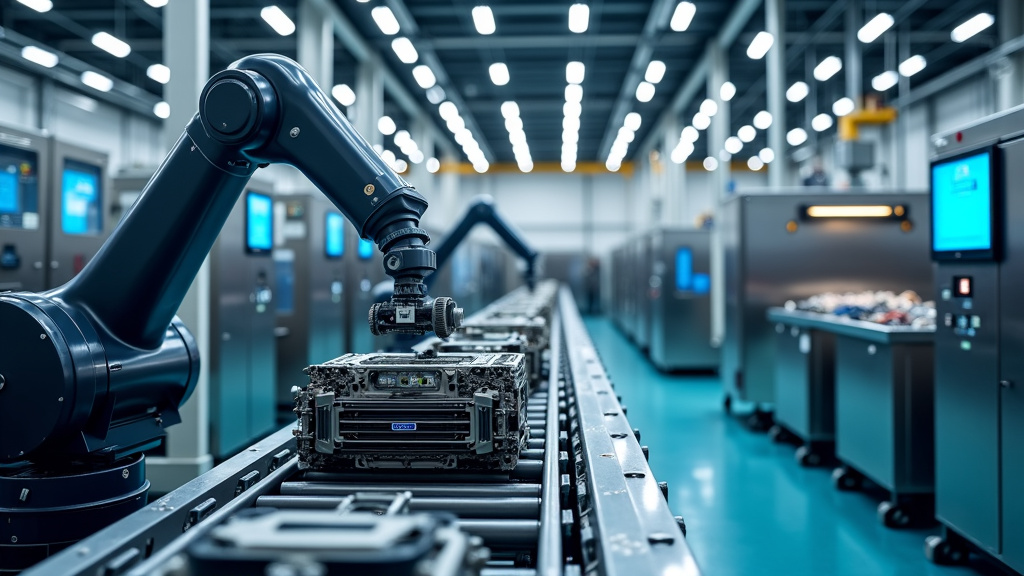

AI-Powered Sorting: Precision in Recycling

Artificial Intelligence is playing a crucial role in Okon Recycling’s large-scale material processing. AI-powered cameras and sensors can detect subtle differences in materials, colors, and shapes with 99% accuracy. These systems are particularly effective at separating different types of plastics, identifying metal grades and compositions, and removing non-recyclable contaminants from waste streams.

A recent implementation of AI sorting robots in a recycling facility reported: Our facility saw a 25% increase in recycling rates and a 70% reduction in sorting errors after deploying AI sorting robots.

By combining these innovative technologies, Okon Recycling is not just recycling materials; they are pioneering a new era in waste management. Their approach demonstrates how modern technology can transform the recycling of complex, large-scale materials, maximizing resource recovery while minimizing environmental impact. As we move towards a more sustainable future, companies like Okon Recycling are leading the way, turning waste management challenges into opportunities for innovation and resource conservation.

Conclusion: Moving Forward with Sustainable Recycling

As we confront the growing challenges of recycling complex systems like commercial AC units, the need for sustainable practices has never been clearer. The path forward requires a collective commitment from businesses and individuals to adopt eco-friendly disposal methods that protect our environment for future generations.

The recycling landscape is rapidly evolving, with innovative solutions emerging to address even the most challenging waste management issues. From advanced techniques for extracting valuable materials to processes that minimize environmental impact, the industry is meeting the demands of our increasingly complex waste streams.

One company at the forefront of this green movement is Okon Recycling. With over a century of experience in the metal recycling industry, Okon has consistently demonstrated its commitment to sustainability and responsible waste management. Their expertise in handling large-scale materials, including commercial HVAC systems, makes them a valuable partner for businesses looking to enhance their environmental stewardship.

By choosing services like those offered by Okon Recycling, we’re actively contributing to a circular economy. These specialized recycling processes ensure that valuable resources are reclaimed and repurposed, reducing the need for raw material extraction and minimizing the carbon footprint associated with manufacturing new products.

Ready to take the next step in your recycling journey? Visit Okon Recycling’s website to learn more about their comprehensive recycling services and how you can contribute to a more sustainable future.