5901 Botham Jean Blvd, Dallas, TX 75215

Exploring the Circular Economy in Construction Waste Recycling

February 13, 2025The construction industry generates 1.3 billion tons of waste annually, underscoring the need for sustainable solutions. The circular economy offers a game-changing approach—keeping materials in use longer, maximizing value, and regenerating resources instead of discarding them.

Designing for disassembly is a core principle, enabling buildings to be deconstructed like a Lego set, with components repurposed rather than demolished. Material passports further support this system by digitally tracking materials, ensuring efficient recovery and reuse.

Okon Recycling leads the charge in circular construction, applying advanced metal recycling and waste management strategies to keep valuable materials in circulation. Through innovation and sustainability, they help close the loop, transforming waste into resources.

Key Strategies for Efficient Construction Waste Recycling

![]()

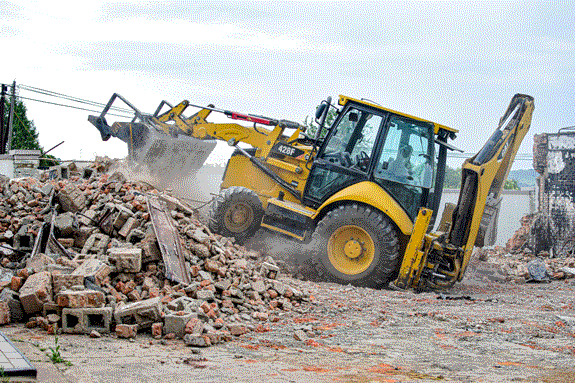

The construction industry generates significant waste, but efficient recycling strategies can reduce environmental impact and enhance sustainability. By adopting advanced technologies and strategic waste management approaches, construction companies can minimize waste and maximize resource reuse.

One effective strategy is selective demolition, which involves carefully dismantling buildings to salvage reusable materials. Instead of indiscriminately demolishing structures, crews deconstruct them methodically to preserve valuable components. Selective demolition can offer cost advantages by reducing waste disposal fees and providing materials for reuse or resale.

Upcycling is another innovative approach gaining traction in construction waste management. This practice involves creatively repurposing waste materials into new products of higher value. For example, old wooden beams might be transformed into stylish furniture, or crushed concrete could become the base material for new roads.

Advanced Technologies for Waste Management

Technology plays a crucial role in optimizing construction waste recycling. Building Information Modeling (BIM) software helps contractors precisely estimate material needs, reducing excess ordering and subsequent waste. On-site sorting systems use artificial intelligence to quickly categorize different types of waste for efficient recycling.

Mobile crushing and screening equipment allows for on-site processing of concrete and other materials, reducing transportation costs and emissions associated with hauling waste to off-site recycling facilities. Additionally, innovative recycling technologies are emerging to process traditionally difficult materials like gypsum drywall.

Some construction firms are exploring robotic systems for waste sorting and handling. These automated solutions can increase sorting accuracy and speed while reducing labor costs and safety risks for workers.

Strategic Planning for Waste Reduction

Effective construction waste recycling begins long before a project starts. Integrating waste management considerations into the design phase can significantly reduce overall waste generation. Architects and engineers can specify standard material sizes to minimize off-cuts and select recyclable or biodegradable materials where possible.

Implementing a comprehensive waste management plan is crucial for any construction project. This plan should outline specific strategies for waste reduction, reuse, and recycling at each project stage. Setting clear targets for waste diversion and recycling rates helps motivate teams and track progress.

| Stage | Step | Description |

| Pre-planning | 1 | Conduct hazard assessments and engage stakeholders |

| Plan Development | 2 | Create a comprehensive waste management plan |

| Plan Maintenance | 3 | Regularly update and review the waste management plan |

| Implementation | 4 | Apply the plan during incidents and conduct oversight |

Collaboration with suppliers can also yield significant waste reduction benefits. Some companies are partnering with material manufacturers to establish take-back programs for unused or off-spec materials, ensuring these resources don’t end up in landfills and can be reprocessed into new products.

Case Study: Sustainable Practices in Action

A recent high-rise project in Seattle demonstrates the potential of efficient construction waste recycling. The development team implemented a rigorous waste management plan that included on-site sorting, mobile recycling equipment, and partnerships with local recycling facilities. Through these efforts, they achieved a remarkable 95% waste diversion rate.

Key to their success was early planning and team-wide buy-in. All subcontractors received training on proper waste sorting procedures, and financial incentives were tied to meeting recycling targets. The project also utilized prefabricated components to reduce on-site waste generation.

By prioritizing waste reduction and recycling, the Seattle project not only minimized its environmental footprint but also realized significant cost savings. The team estimates they saved over $200,000 in waste disposal fees and material purchases through their recycling and reuse efforts.

Overcoming Challenges in Construction Waste Recycling

While the benefits of efficient construction waste recycling are clear, implementing these strategies is not without challenges. One common hurdle is the initial cost of investing in new technologies and processes. However, many companies find that these upfront expenses are quickly offset by reduced waste disposal fees and material savings.

Another challenge is ensuring proper waste sorting across large, complex job sites. Clear labeling, regular training, and consistent monitoring are essential to maintain high recycling rates. Some firms are using wearable technology and mobile apps to provide real-time guidance to workers on proper waste handling procedures.

Contamination of recyclable materials remains an ongoing concern. Even small amounts of non-recyclable items can render entire loads of otherwise recyclable waste unusable. Rigorous quality control measures and partnerships with recycling facilities that can handle mixed materials are helping address this issue.

The Future of Construction Waste Recycling

As sustainability becomes increasingly critical in the construction industry, we can expect to see continued innovation in waste recycling strategies. Emerging technologies like artificial intelligence and advanced robotics promise to further optimize sorting and processing of construction waste.

There’s also growing interest in ‘design for deconstruction’ principles, where buildings are engineered from the outset to be easily dismantled and recycled at the end of their lifecycle. This holistic approach to sustainability could revolutionize how we think about the entire building process.

By embracing these key strategies for efficient construction waste recycling, the industry can significantly reduce its environmental impact while improving overall sustainability and resource efficiency. As technologies advance and best practices evolve, the goal of near-zero waste construction may soon become a reality.

Benefits of Implementing Circular Economy in Construction

The construction industry is shifting towards sustainability by adopting circular economy principles, offering numerous benefits such as significant reductions in carbon emissions and enhanced resource efficiency. By reimagining material and process lifecycles, the sector is paving the way for a more environmentally responsible and economically viable future.

Environmental Benefits: Slashing Carbon Footprints

A key advantage of implementing circular economy practices in construction is the substantial decrease in carbon emissions. Traditional construction methods are known for their large carbon footprint, but circular approaches are changing this. By prioritizing recycled and repurposed materials, the industry can significantly reduce the need for virgin resource extraction and processing, which are energy-intensive activities.

For example, using recycled concrete aggregates (RCA) in new construction projects can lead to a 5.5% reduction in carbon content. While this percentage may seem small, it translates to massive reductions when applied globally. Moreover, using larger aggregate sizes can enhance carbon reduction by up to 14%, highlighting the potential for significant environmental gains through thoughtful material selection and design.

The circular economy model also promotes the development of buildings designed for disassembly. This approach ensures that at the end of a structure’s life, its components can be easily separated and reused or recycled, minimizing waste and associated carbon emissions from demolition and disposal.

Resource Efficiency: Maximizing Material Value

Circular economy principles in construction advocate for efficient resource use throughout a building’s lifecycle. This efficiency starts at the design stage, where architects and engineers consider how materials can be optimized, reused, and eventually recycled, resulting in benefits that extend beyond the construction phase.

A striking example of resource efficiency is the reuse of excavated earth. Instead of dumping it in landfills, innovative companies are recycling it into new construction materials. This practice reduces waste, minimizes transportation emissions, and decreases the need for new raw materials. Locally excavated earth is being transformed into eco-friendly building materials like clay plasters and compressed earth blocks, showcasing the potential for local, low-impact construction solutions.

Additionally, adopting modular construction techniques aligns perfectly with circular economy goals. Modular units can be easily reconfigured, repurposed, or relocated, extending their useful life and reducing the demand for new materials. This approach conserves resources and offers flexibility in building design and use, a valuable asset in our rapidly changing urban environments.

Economic Advantages: Cost Savings and New Opportunities

The circular economy in construction presents compelling economic benefits. By reducing waste and maximizing material value, companies can achieve significant cost savings. The reuse and recycling of construction materials can lower procurement expenses and minimize disposal costs, improving project economics.

Furthermore, the circular approach is creating new business models and job opportunities within the sector. Specialized roles in material recovery, recycling, and innovative design are emerging, creating a more diverse and resilient construction economy. Companies like BC Materials are pioneering the transformation of excavated earth into valuable construction materials, demonstrating how circular principles can drive innovation and create new market niches.

The economic benefits also extend to building owners and operators. Structures designed with circular principles often have lower maintenance costs and greater adaptability, potentially increasing their long-term value and reducing the need for costly renovations or demolitions.

Real-World Success: Circular Economy in Action

To appreciate the impact of circular economy principles in construction, consider these real-world examples:

- Park 20|20 in the Netherlands: This business park was designed using Cradle to Cradle principles, focusing on material reusability and waste reduction. Buildings were constructed for easy disassembly, ensuring materials could be efficiently recycled or repurposed at the end of their lifecycle.

- The Circular Building, London: This temporary structure showcased circular economy principles in action. Every component was designed for disassembly, and all materials were reusable or recyclable, demonstrating the feasibility of circular construction practices.

- Pixelcrete in office buildings: By using 100% reclaimed and recycled aggregates, this innovative concrete mix reduced Portland cement content by 60% compared to conventional concrete, leading to a reduction of 73.8 tonnes of CO2 equivalent in greenhouse gas emissions.

| Country | Project | Industry | Main Achievement |

|---|---|---|---|

| Poland | FAKRO PVC Recycling | Construction | Repurposing PVC waste for window production |

| Austria | Wolf Nudeln | Food | First pasta producer using paper packaging |

| Slovenia | BioTHOP | Agriculture | Biodegradable packaging from hop waste |

| Czech Republic | Hydal | Chemicals | Converting frying oil into bioplastic |

| Germany | HolyPoly | Plastics | Recycling plastics into new products |

These examples illustrate that the benefits of implementing circular economy principles in construction are not theoretical but are being realized in projects worldwide. As more companies and governments recognize the value of this approach, we can expect even more innovative and impactful implementations in the future.

The construction industry stands at a pivotal moment, with the opportunity to redefine its relationship with the environment and resources. By embracing circular economy principles, the sector can significantly reduce its carbon footprint, enhance resource efficiency, and unlock new economic opportunities. The circular economy offers a blueprint for a more sustainable and prosperous future in construction as we continue to build the cities and infrastructure of tomorrow.

Challenges and Solutions in Construction Waste Recycling

The construction industry faces significant hurdles in effectively recycling waste materials. Two primary challenges are logistical constraints and the need for improved stakeholder collaboration. However, innovative solutions are emerging to tackle these issues directly.

Logistical Constraints in Construction Waste Recycling

A major challenge in construction waste recycling is managing complex logistics. Construction sites generate large volumes of diverse materials, making sorting and transportation daunting.

Space limitations on many sites exacerbate this issue. Limited room for waste segregation and storage hinders effective on-site recycling practices.

Additionally, transporting recyclable materials to appropriate facilities can be costly and time-consuming, discouraging contractors from prioritizing recycling, especially on smaller projects with tight budgets.

Innovative digital solutions are emerging to address these logistical challenges. Advanced material tracking systems, powered by AI and IoT, are transforming how construction waste is managed.

These digital tools enable real-time monitoring of material flows, from delivery to disposal or recycling. Providing accurate data on waste generation and movement helps optimize collection schedules and reduce unnecessary transportation costs.

Enhancing Stakeholder Collaboration

Another critical challenge is the lack of effective collaboration among stakeholders, including contractors, subcontractors, suppliers, waste management companies, and regulatory bodies.

Without proper coordination, recycling efforts can become fragmented and inefficient. Different parties may have conflicting priorities or lack a shared understanding of recycling goals and processes.

Communication gaps between stakeholders can lead to missed recycling opportunities, resulting in valuable resources ending up in landfills unnecessarily.

To overcome these collaboration challenges, the industry is turning to digital platforms that facilitate better communication and data sharing. These tools create a centralized hub for all stakeholders to access and update waste management information.

Cloud-based project management systems allow for real-time updates on recycling targets, waste generation data, and available recycling options. This transparency helps align all parties toward common sustainability goals.

Innovative Solutions for Material Tracking

Digital material tracking solutions are at the forefront of addressing both logistical and collaboration challenges in construction waste recycling. These systems leverage cutting-edge technologies to provide unprecedented visibility into the waste management process.

AI-powered analytics can predict waste generation patterns, allowing for proactive planning of recycling efforts. This helps construction teams anticipate recycling needs and allocate resources more efficiently.

Mobile apps and IoT sensors enable workers to easily log and track waste materials in real-time. This data can be instantly shared with all relevant stakeholders, ensuring everyone has up-to-date information on recycling progress.

Blockchain technology is also being explored to create tamper-proof records of material lifecycles. This can enhance accountability and trust among stakeholders, particularly when verifying the origin and destination of recycled materials.

Building Stronger Stakeholder Partnerships

Improving stakeholder collaboration goes beyond implementing new technologies. It requires a fundamental shift in how construction projects approach waste management and sustainability.

Educational initiatives play a crucial role in fostering a culture of recycling among all stakeholders. Training programs can help workers understand the importance of proper waste sorting and recycling practices.

Establishing clear recycling goals and incentives for all project participants can align interests and motivate collective action. This might include incorporating recycling performance into contract evaluations or offering rewards for exceeding recycling targets.

Regular stakeholder meetings focused specifically on waste management can provide a forum for addressing challenges, sharing best practices, and celebrating successes. This ongoing dialogue is essential for continuous improvement in recycling efforts.

By combining innovative digital solutions with stronger stakeholder partnerships, the construction industry can overcome the challenges of waste recycling. These efforts benefit the environment and contribute to more efficient and cost-effective project management.

| Digital Solution | Key Features | Benefits |

|---|---|---|

| AI and Predictive Analytics | Forecast material needs, optimize logistics | Reduces overordering, minimizes waste |

| BIM (Building Information Modeling) | 3D modeling, lifecycle analysis | Improves material efficiency, reduces waste |

| IoT (Internet of Things) | Real-time monitoring, material tracking | Enhances resource utilization, reduces waste |

| Robotics and Automation | Automated sorting, material handling | Increases sorting accuracy, reduces labor costs |

| Blockchain | Traceability, smart contracts | Ensures transparency, improves compliance |

Conclusion: Towards a Sustainable Future in Construction Waste Recycling

The construction industry stands at a turning point where sustainability must be a priority. Embracing circular economy practices and waste recycling isn’t just about reducing landfill waste—it’s about building a greener future.

Recycling materials and minimizing waste significantly reduce the environmental impact of construction. Diverting debris from landfills and conserving resources bring both immediate and long-term benefits.

Okon Recycling is leading this transformation, proving that even complex construction waste can become valuable resources. Through advanced sorting techniques and sustainable solutions, they demonstrate how innovation can drive environmental progress.

Sustainable construction is not just an ethical choice—it’s a competitive advantage. With tightening regulations and increasing public awareness, companies that prioritize recycling and waste reduction will be ahead of the curve.

Now is the time for action. Contractors, suppliers, and policymakers all play a role in shaping an industry where sustainability is the norm. By supporting recycling initiatives and investing in green technologies, we can turn construction waste into an opportunity for lasting change.

Let’s build a future where every project contributes to environmental preservation. Contact Okon Recycling at 214-736-9509 to explore tailored recycling solutions that support sustainable construction.