5901 Botham Jean Blvd, Dallas, TX 75215

The Rise of Circular Economy in Rail Equipment

April 16, 2025The rail industry generates approximately 2.6 million tonnes of waste annually from ballasted tracks alone. This significant figure highlights the importance of circular economy principles in modern railway operations. The industry is transitioning from the traditional “take-make-discard” linear model to more sustainable practices that focus on material reuse and waste reduction.

Major railway organizations across Europe, including DB in Germany, SNCF in France, and Network Rail in the UK, are implementing ambitious circular economy projects focused on rail equipment. These initiatives set concrete targets, such as DB’s goal to increase recycling rates to 45% for rails, 30% for concrete sleepers, and 40% for ballast. These efforts align with the European Commission’s Circular Economy Action Plan (CEAP), which emphasizes the construction and building sectors as crucial in achieving sustainability goals.

The rail sector’s adoption of circularity is not just environmental posturing. It represents a fundamental rethinking of how railway infrastructure is designed, maintained, and repurposed.

What Are Key Circular Economy Initiatives in Rail Equipment?

The rail industry leads in applying circular economy principles, creating innovative ways to extend material lifespans and reduce waste. Several initiatives are transforming railway equipment management, maintenance, and recycling. These programs aim to establish sustainable resource management systems, delivering environmental and economic benefits.

Leading Circular Economy Programs in Railways

The International Union of Railways (UIC) has launched several initiatives changing the rail sector’s approach to material use. These programs focus on maximizing resource efficiency and minimizing waste:

- REUSE Project: This UIC-led initiative provides railway companies with strategies for sustainable resource management. It targets high-volume materials like ballast, steel rails, and concrete sleepers, identifying reuse and recycling opportunities while helping companies prepare for potential resource scarcity and price volatility.

- Network Rail’s SURPLUS App: This innovative internal asset redistribution platform allows employees to relocate materials no longer needed in one area to another part of the business. Since its launch in 2019, the app has cataloged approximately £40 million worth of assets that might otherwise have been discarded, creating financial efficiencies while reducing waste.

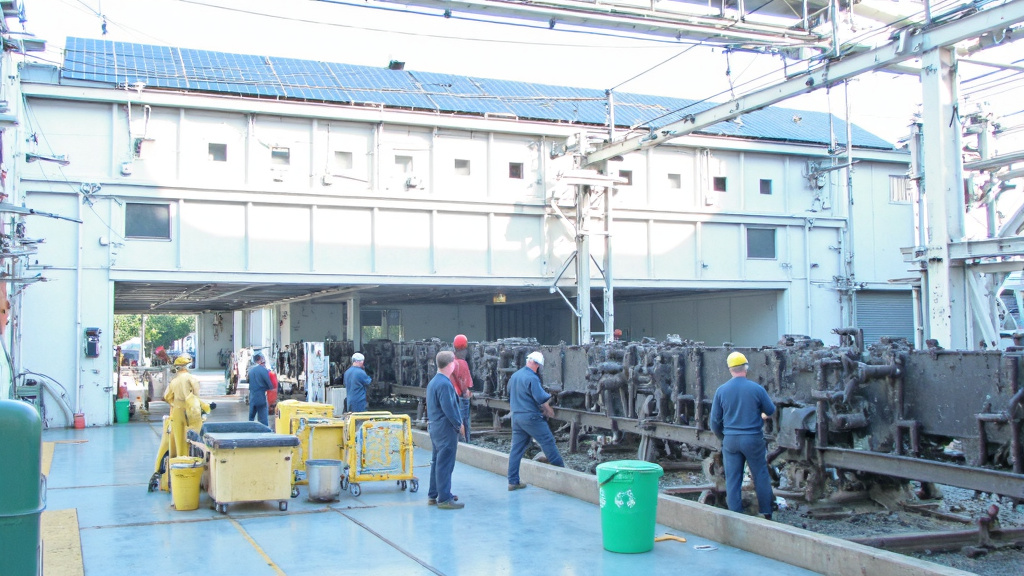

- Dedicated Recycling Facilities: Railway companies across Europe are establishing specialized centers for processing and recovering materials. For example, Network Rail’s Whitemoor Aggregate Handling Depot processes 40-50 wagons of track materials weekly, sorting them for reuse or external sale.

- SNCF RESEAU’s Recycling Strategy: France’s rail infrastructure manager aims to reuse or recycle 100 percent of main rail components by 2025. They’ve established facilities like the Miramas recycling center, which processed 30,000 tonnes of ballast in 2020, with approximately 60% reinstalled in rail operations.

Beyond these major initiatives, railways are developing innovative approaches for specific materials and components:

- Rail-for-Rail Projects: Programs that repurpose worn rails into new rail products, closing the material loop.

- Green Procurement Practices: Environmental Cost Indicator (ECI) methodologies that factor environmental impacts into purchasing decisions.

- Alternative Materials Research: Development of railway sleepers made from recycled plastics and other sustainable materials.

Case Study: Deutsche Bahn’s Circular Approach

Germany’s Deutsche Bahn (DB) exemplifies how comprehensive circular economy principles can integrate throughout a railway system. DB has committed to a 95% recycling rate across all waste streams and is making significant progress through several interconnected initiatives:

In 2020, DB reconditioned 240,000 concrete sleepers (approximately 72,000 tons), representing about 10% of all installed concrete sleepers. Their ballast recycling program returned 515,000 tons of cleaned ballast to the existing track network – 16% of all installed ballast. Materials unsuitable for railway reuse were diverted to other sectors, such as road construction.

DB evaluates its material impacts using a self-developed Green Evaluation Tool that tracks three key indicators: cumulated raw material expenditure, energy consumption, and global warming potential. This comprehensive approach allows DB to quantify the environmental benefits of its circular initiatives while identifying areas for further improvement.

The rail industry’s adoption of circular economy principles demonstrates how traditional infrastructure sectors can transform operational models to enhance business efficiency and environmental sustainability. By extending material lifecycles, creating closed-loop systems, and developing innovative recycling methodologies, railways are establishing themselves as leaders in sustainable resource management.

How Are Railway Companies Implementing Sustainable Procurement?

Sustainable procurement is becoming a key component of the circular economy in the railway industry. As environmental concerns grow, rail companies are increasingly adopting procurement strategies to minimize waste, reduce resource consumption, and lower carbon emissions throughout their supply chains.

One significant industry initiative is Railsponsible, launched in March 2015 by major railway companies including Alstom, Bombardier, Deutsche Bahn, Knorr Bremse, Nederlandse Spoorwegen, and SNCF. This collaborative platform enables railway operators and manufacturers to systematically evaluate their suppliers’ sustainability performance through a shared assessment tool powered by EcoVadis.

Companies like ProRail in the Netherlands are using tools such as the Environmental Cost Indicator (ECI) to evaluate procurement bids based on environmental impact rather than just price. The ECI assigns monetary values to various environmental impacts, translating environmental damage into financial terms that can be incorporated into bid evaluations. This allows procurement teams to weigh sustainability alongside traditional criteria like cost and technical specifications.

Stefan Braun, President of Railsponsible and Chief Procurement Officer at ÖBB, highlights the importance of finding the optimal balance: “The best possible result is where ecology and economy meet. It requires an ambitious approach and significant efforts along the entire supply chain, achievable only with our suppliers and partners.”

Other Innovative Procurement Approaches

Beyond assessment tools, railway companies are adopting innovative procurement approaches such as ‘Design, Bid, and Build’ methodologies that prioritize sustainability from the project’s earliest stages. These approaches reward designs that minimize virgin material consumption, encourage recycled materials, and promote innovative sustainable methods from contractors.

The rail industry is also emphasizing lifecycle assessment in procurement decisions. Rather than focusing solely on upfront costs, companies consider the total environmental impact of products and services throughout their lifecycle—from raw material extraction through manufacturing, use, and eventual disposal or recycling.

Deutsche Bahn is addressing the challenge of understanding its entire supply chain, including Tier 2 suppliers. This deeper visibility allows the company to better identify sustainability risks and opportunities across the supply network and engage more effectively with suppliers on environmental improvements.

Nederlandse Spoorwegen (NS) is focusing on making its supply chain more circular. Working with EcoVadis to evaluate suppliers, NS recognizes that improving its sustainability performance requires addressing the environmental impact of its entire supply chain.

The collaborative nature of sustainable procurement in the railway sector reflects a recognition that environmental challenges cannot be solved by individual companies alone. By sharing best practices, establishing common assessment methodologies, and engaging collectively with suppliers, railway companies are creating industry-wide momentum toward more sustainable operations.

Industry leaders acknowledge that sustainable procurement requires a significant transformation in how railway companies interact with their suppliers. As Jeroen Wegkamp, Chief Procurement Officer at Nederlandse Spoorwegen, notes: “Sustainability is a topic where railway operators and manufacturers must work together—it is inherently non-competitive… Our goal is to elevate the sustainability performance of the railway supply chain structurally.”

| Aspect | Traditional Procurement | Sustainable Procurement |

|---|---|---|

| Material Sourcing | Focus on cost-efficiency | Prioritizes recycled and low-carbon materials |

| Supplier Selection | Based on price and quality | Includes sustainability certifications like ISO 14001 |

| Environmental Impact | Not a primary concern | Reduces carbon emissions and promotes resource efficiency |

| Lifecycle Consideration | Limited to purchase phase | Considers environmental impacts across the entire lifecycle |

| Innovation | Less emphasis | Encourages innovative sustainable methods |

The shift toward sustainable procurement in rail is more than a trend—it’s becoming integral to how railway companies operate in a carbon-constrained world. By using procurement as a strategic tool for environmental improvement, the rail sector is solidifying its position as one of the most sustainable transportation modes while driving innovation throughout its supply chain.

Conclusion: The Future of Circular Economy in Rail Equipment

Circular economy principles are profoundly reshaping the rail industry, creating pathways toward enhanced sustainability and resource efficiency once thought impossible. The shift from traditional take-make-waste models to regenerative closed-loop systems represents more than an environmental initiative—it is becoming a competitive necessity in the evolving transportation landscape.

As railway operators, manufacturers, and stakeholders continue to embrace circular practices such as asset life extension, remanufacturing, and product-as-a-service models, the environmental and economic benefits multiply. Cross-sector collaboration is emerging as a critical enabler, with circular economy syndicates forming to optimize resource use across the entire rail ecosystem. Innovations currently underway—from standardized interfaces that promote interoperability to advanced monitoring systems that extend asset lifecycles—are collectively establishing rail as the sustainability leader in transportation.

The future of rail equipment undoubtedly lies in circularity, offering tremendous potential for both sustainability impact and economic viability. For stakeholders wanting to participate in this transformative journey, contact Okon Recycling at 214-717-4083.