5901 Botham Jean Blvd, Dallas, TX 75215

Sustainable Rare Metal Recycling Initiatives

March 13, 2025Did you know that less than 1% of critical rare earth elements are recycled globally, despite their essential role in technologies vital for a sustainable future? This statistic highlights the urgent need for sustainable rare metal recycling initiatives in our resource-constrained world. As demand for these materials rises, with some projections estimating a 300-600% increase by 2050, the importance of developing robust recycling programs cannot be overstated.

Rare metals, including elements like neodymium, dysprosium, and terbium, are crucial in powering our transition to a greener economy. They are key components in everything from wind turbines and electric vehicles to energy-efficient lighting and advanced electronics. However, their extraction comes at a significant environmental cost. Traditional mining practices can lead to habitat destruction, water pollution, and the release of toxic chemicals, creating an unsustainable paradox where materials intended to drive environmental progress cause ecological harm in their production.

This is where sustainable rare metal recycling initiatives offer hope. These programs aim to recover and reuse valuable rare metals from electronic waste and other sources, reducing environmental impact and conserving our planet’s finite natural resources.

The Importance of Rare Metal Recycling

Imagine holding your smartphone and realizing it contains more precious metals than a gold mine. While that may sound far-fetched, the reality isn’t far off. Modern devices are rich in rare metals, each playing a crucial role in our tech-driven world. From the neodymium in your headphones’ magnets to the indium in your touchscreen, these elements are vital to our digital era.

Rare metals, despite their name, aren’t necessarily scarce in the Earth’s crust. However, they are often found in low concentrations, making extraction challenging and environmentally costly. Consider this: producing just one ton of rare earth elements can generate up to 2,000 tons of toxic waste, a staggering environmental price for our technological progress.

The true cost of rare metal mining extends far beyond mere numbers. In places like China’s rare earth mining regions, ecosystems have been devastated. Soil and water pollution have reached alarming levels, with some areas dubbed “cancer villages” due to elevated disease rates linked to toxic exposure. This stark reminder shows that our hunger for technology often comes at a steep price paid by vulnerable communities and fragile ecosystems.

The Technology Dependence Dilemma

Our reliance on rare metals isn’t just about convenience; it’s a cornerstone of modern innovation. Take renewable energy systems, for instance. A single wind turbine can contain up to 2 tons of rare earth elements, primarily neodymium and dysprosium. Electric vehicles, heralded as the future of transportation, require significantly more rare metals than their gas-powered counterparts.

This dependence creates a paradox. As we strive for greener technologies to combat climate change, we risk causing severe environmental damage through increased rare metal mining. It’s a classic case of robbing Peter to pay Paul, highlighting the urgent need for more sustainable practices in the tech industry.

The Recycling Revolution

Recycling offers hope in the rare metal conundrum. By recovering these precious elements from discarded electronics, we can significantly reduce the need for new mining operations. The potential is enormous. A single ton of recycled smartphones can yield more gold than 17 tons of gold ore. Yet, currently, less than 1% of rare earth elements are recycled globally.

No table output available

Recycling rare metals isn’t just about conservation; it’s a matter of economic and national security. China currently dominates the global rare earth supply chain, accounting for over 80% of production. This monopoly has led to price volatility and supply concerns, particularly for industries reliant on these materials.

By developing robust recycling programs, countries can reduce their dependence on foreign sources and create a more stable supply of these critical materials. It’s a win-win: less environmental damage, reduced geopolitical tensions, and a step towards a more circular economy.

The Path Forward

The transition to a rare metal recycling economy won’t be easy, but it’s necessary. It requires a multifaceted approach involving governments, industries, and consumers. Policies incentivizing the recycling of electronic waste, investments in recycling technologies, and consumer education about proper e-waste disposal are crucial steps.

Innovative companies are already leading the way. Apple, for instance, has developed a robot named Daisy that can disassemble up to 200 iPhones per hour, efficiently recovering valuable materials. Such initiatives need to become the norm rather than the exception.

As consumers, we play a vital role too. The next time you upgrade your phone or laptop, consider the rare metals within it. By properly recycling our electronics, we can each contribute to a more sustainable future—one where our technological progress doesn’t come at the expense of our planet’s health.

The importance of rare metal recycling cannot be overstated. It’s not just about preserving resources; it’s about reimagining our relationship with technology and the Earth. As we stand at the crossroads of innovation and sustainability, the choices we make today will shape the world of tomorrow. Let’s choose wisely.

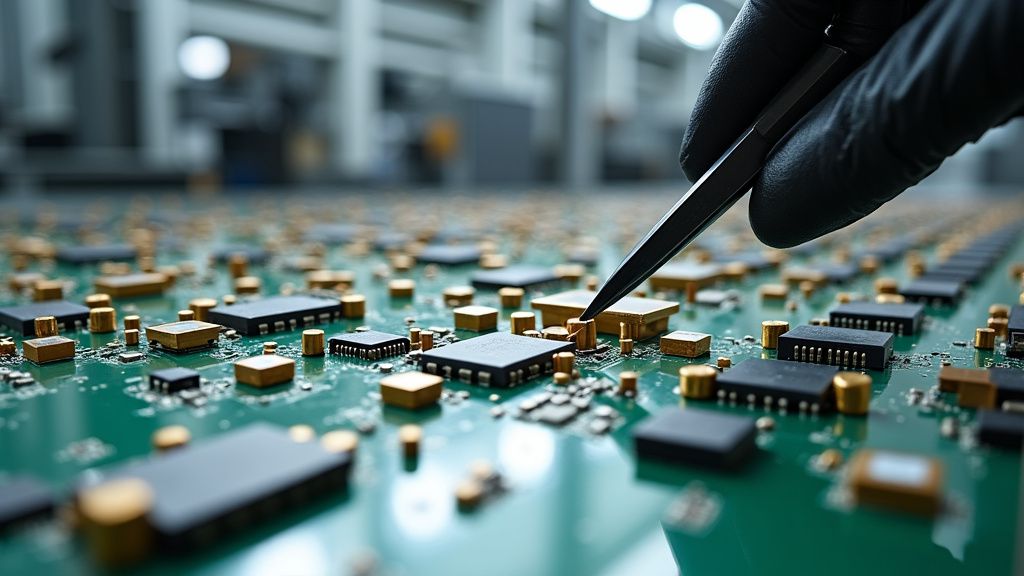

Innovative Rare Metal Recycling Technologies

The recycling landscape is transforming remarkably, with advanced technologies enhancing how we recover valuable rare metals from waste streams. These advancements represent significant leaps in our ability to extract and reuse critical materials once considered economically unviable to recycle.

Leading this transformation are sophisticated sorting techniques. Advanced sensors and artificial intelligence now work together to identify and separate rare metals with exceptional accuracy. For instance, X-ray fluorescence (XRF) technology can rapidly analyze the chemical composition of materials at transfer points, ensuring the quality and purity of recycled metals.

Chemical processes have also advanced significantly. The SOLCRIMET project, funded by the European Research Council, has pioneered using low-pollution solvents with electric charges to extract rare earth elements, indium, and cobalt from discarded technology. This innovative approach, known as solvometallurgy, offers a greener alternative to traditional hydrometallurgical methods that rely on harsh acids and generate significant waste.

Breakthrough in Rare Earth Recovery

A particularly exciting breakthrough comes from researchers at Rice University, who have developed a technique called flash joule heating. This method uses rapid bursts of electricity to heat electronic waste to extremely high temperatures, breaking down complex materials and separating valuable rare earth elements in seconds. The process is not only incredibly fast but also remarkably efficient, consuming significantly less energy than conventional recycling methods.

What makes flash joule heating particularly revolutionary is its versatility. Unlike many recycling techniques tailored to specific types of waste, this method can be applied to a wide range of electronic devices, from smartphones to circuit boards. It offers a universal solution for recovering diverse precious materials that would otherwise end up in landfills.

The Rise of Biohydrometallurgy

Another frontier in rare metal recycling is biohydrometallurgy. This approach uses microorganisms to extract metals from waste. Certain bacteria can leach rare earth elements from discarded electronics, offering a low-energy, environmentally friendly alternative to traditional chemical processes. While still in its early stages, this biological approach holds immense promise for sustainable metal recovery.

The implications of these technological advancements are profound. They promise to reduce the environmental impact of electronic waste and offer a solution to the growing scarcity of rare metals essential for modern technologies. By creating more efficient recycling pathways, we can build a more circular economy for these critical resources.

As these innovations continue to evolve, the future of rare metal recycling looks increasingly bright. From AI-powered sorting to microbial extraction, the field is ripe with potential for further breakthroughs. For industries reliant on these precious materials, and for the planet, these advancements are timely.

| Technology | Description | Benefits |

| Sensor-Based Sorting | Uses sensors like XRF, XRT, and NIR to separate metals based on physical and chemical properties. | Improves efficiency and purity of recycled materials. |

| Automated Robotics | Robotic systems with AI for automating the sorting process. | Enhances sorting capabilities and accuracy. |

| Hydrometallurgical Processes | Uses aqueous chemistry to extract metals at lower temperatures. | More energy-efficient, produces fewer pollutants. |

| Electrochemical Recycling | Involves electric currents to dissolve and separate metals from waste. | Effective for high-purity metal recovery, especially e-waste. |

| Solvometallurgy | Uses low-pollution solvents with electric charges for metal extraction. | Greener alternative, reduces waste and pollution. |

| Flash Joule Heating | Uses electricity for rapid heating to separate rare earth elements. | Fast, efficient, and energy-saving. |

| Biohydrometallurgy | Utilizes microorganisms to extract metals from waste. | Low-energy, environmentally friendly process. |

Global Initiatives and Policies for Sustainable Rare Metal Recycling

As the demand for rare metals continues to increase, governments and international organizations are actively promoting sustainable recycling practices. These initiatives aim to foster a circular economy for rare metals, minimizing environmental impact and ensuring a stable supply for future generations.

Extended Producer Responsibility Programs

Many countries are implementing Extended Producer Responsibility (EPR) programs to make manufacturers accountable for their products’ entire lifecycle. Japan, a leader in this approach, has established a strong EPR system for electronic waste, requiring manufacturers to collect and recycle their products at the end of their useful life.

The impact of Japan’s EPR program has been significant. According to a United Nations University report, Japan has achieved one of the highest e-waste collection rates globally, with over 50% of discarded electronics being properly collected and recycled. This success story highlights the potential of EPR programs in fostering sustainable rare metal use.

Incentives for Recycling

Governments are also offering financial incentives to encourage rare metal recycling. In China, the world’s largest producer and consumer of rare earth elements, authorities have introduced subsidies for companies engaging in rare earth recycling. These incentives have significantly increased recycling efforts, with some regions reporting up to a 30% reduction in rare earth mining activities.

The European Union has adopted a similar approach through its Horizon Europe program, which funds innovative recycling technologies. One notable project, SUSMAGPRO, focuses on developing sustainable recovery, recycling, and reuse processes for rare-earth magnets. This initiative not only promotes recycling but also fosters technological innovation.

Regulations on Electronic Waste Management

Strict regulations on electronic waste management are being implemented worldwide to ensure the proper handling and recycling of rare metals. The European Union’s Waste Electrical and Electronic Equipment (WEEE) Directive sets collection, recycling, and recovery targets for all types of electrical goods, leading to significant improvements in e-waste management across Europe.

In the United States, individual states are leading e-waste regulation efforts. California’s Electronic Waste Recycling Act, for instance, has been particularly effective. Since its implementation in 2005, the program has led to the recycling of over 2 billion pounds of electronic waste, recovering substantial amounts of rare metals.

International Cooperation

Recognizing the global nature of the rare metal supply chain, international organizations are fostering cooperation among countries. The United Nations Environment Programme (UNEP) has launched initiatives to promote sustainable rare metal management, including the Global Partnership on Waste Management, which facilitates knowledge sharing and best practices in e-waste recycling.

These collaborative efforts are crucial in addressing the challenges of rare metal recycling. By sharing technologies, strategies, and resources, countries can work together to create a more sustainable and circular approach to rare metal use.

As these global initiatives and policies continue to evolve, they pave the way for a more sustainable future in rare metal use. From extended producer responsibility to international cooperation, these efforts demonstrate a growing commitment to creating a circular economy for rare metals. By learning from successful examples and continuing to innovate, we can ensure that these valuable resources are managed responsibly for generations to come.

No table output available

Challenges in Rare Metal Recycling

The recycling of rare metals is a complex but essential task in our tech-driven world. As demand for these elements increases, particularly in clean energy technologies, efficient recycling practices are more crucial than ever. However, several significant hurdles impede widespread adoption.

One primary challenge is the intricate process of extracting rare metals from electronic components. Unlike common materials like aluminum or steel, rare earth elements are often dispersed in minute quantities throughout devices, making separation a delicate and technologically demanding task. For instance, a typical smartphone may contain mere grams of rare earth metals, integrated into various components from speakers to vibration motors.

The complexity extends beyond extraction. Many recycling processes for rare metals are currently prohibitively expensive, especially compared to primary mining costs. This economic barrier has deterred many potential recyclers and investors. However, recent research suggests that innovative technologies, such as intelligent identification systems for non-magnetic materials, could streamline these processes, potentially reducing costs over time.

Collection Conundrum

Another significant obstacle is the lack of standardized collection systems for electronic waste containing rare metals. In many regions, e-waste ends up in landfills or informal recycling sectors, where valuable rare metals are lost, and environmental hazards are created. Establishing efficient, widespread collection networks is crucial but requires coordination between governments, industries, and consumers.

The global nature of rare metal supply chains adds complexity. With China dominating much of the rare earth element production and processing, geopolitical tensions can disrupt both supply and recycling efforts. This reality underscores the importance of developing diverse, localized recycling capabilities to enhance supply chain resilience.

Innovative Solutions on the Horizon

While these challenges are significant, they also present opportunities for innovation. Researchers and companies are exploring groundbreaking techniques to improve rare metal recovery. For example, some scientists are investigating the use of bacteria to extract rare earth elements from electronic waste, offering a potentially more environmentally friendly and cost-effective method.

Moreover, advancements in robotics and artificial intelligence could revolutionize the sorting and disassembly of e-waste, making rare metal recycling more efficient and economically viable. These technologies have the potential to overcome the precision challenges that currently make manual recycling processes labor-intensive and costly.

As we address these recycling challenges, it’s crucial to view them not as insurmountable barriers, but as catalysts for innovation. By fostering collaboration between scientists, engineers, policymakers, and industry leaders, we can develop creative solutions that transform rare metal recycling from a niche practice into a cornerstone of sustainable technology production.

| Challenge | Innovative Solution |

|---|---|

| Technical Complexity | AI-driven sorting systems |

| Economic Viability | Investment in advanced recycling technologies |

| Regulatory and Environmental Issues | Supportive regulatory frameworks |

How Okon Recycling Can Help with Sustainable Rare Metal Recycling Initiatives

With electronic waste becoming a significant environmental concern, Okon Recycling stands out as a leader in sustainable rare metal recycling. This Dallas-based company, with over a century of experience, has evolved with the recycling industry, consistently updating its methods to meet current sustainability needs.

Okon’s approach to rare metal recycling is highly customized. The company develops tailored solutions for each business partner, taking into account their specific sustainability objectives and regulatory requirements.

Central to Okon’s operations is a 20-acre, state-of-the-art facility. This modern hub combines cutting-edge technology with decades of expertise to efficiently recover valuable rare metals from various sources.

Leading Electronic Waste Management

Electronic waste, or e-waste, is among the fastest-growing waste streams worldwide. Okon Recycling is at the forefront of addressing this issue. The company’s advanced processes are designed to extract rare metals from discarded electronics, turning waste into valuable resources.

This focus on e-waste is not just about waste management; it’s about urban mining. By efficiently recovering rare earth elements and other precious metals from electronic devices, Okon helps reduce the need for environmentally harmful mining practices while addressing the e-waste problem.

The company continuously refines its recycling techniques, from advanced sorting technologies to chemical processes that maximize metal recovery, pushing the boundaries of sustainable recycling.

Tailored Solutions for Business Sustainability

Recognizing that each business faces unique sustainability challenges, Okon Recycling offers customized recycling programs. These solutions integrate seamlessly with a company’s operations, minimizing disruption while maximizing material recovery.

The process starts with a thorough evaluation of the client’s workflow and waste streams. Okon’s experts then design a recycling program that optimizes scrap value and aligns with the company’s sustainability goals. This may involve on-site collection systems, specialized sorting processes, or modifications to the client’s product lifecycle management.

Okon’s services go beyond collection and processing. The company provides detailed reporting and analytics, offering clients insights into their recycling efforts and their environmental impact. This data-driven approach enables businesses to quantify their sustainability efforts, essential in today’s eco-conscious market.

| Public Recycling | Providing recycling and scrap metal services for individuals and their communities. |

| Commercial Scrap | Improving scrap metal recycling systems for businesses, industries, and commercial entities. |

| Parts Harvesting | The dismantling, inventory, repackaging, and handling of harvested materials. |

| Magnet Recycling | Recycling permanent, electromagnetic, superconducting MRI magnets, and rare earth and neodymium magnets. |

| On-Site Recycling | Complete demolition job site collection, haul, and removal of scrap metal. |

| Renewable Energy Recycling | Customized recycling solutions for e-waste, magnets, oil and gas, and AC systems. |

Navigating Regulatory Requirements

In the rare metal recycling industry, compliance with evolving regulations is crucial. Okon Recycling uses its decades of experience to help clients navigate this complex landscape. The company’s deep understanding of local and international regulations ensures all recycling processes are efficient and compliant.

This expertise is vital when dealing with e-waste, which often contains hazardous materials along with valuable rare metals. Okon’s processes are designed to safely handle these materials, ensuring environmental protection while maximizing resource recovery. The company’s commitment to compliance provides peace of mind for businesses, allowing them to focus on their core operations.

As regulations evolve, especially in electronic waste management, Okon stays ahead by updating its processes and advising clients on best practices. This proactive approach ensures businesses partnering with Okon remain compliant and sustainable.

Supporting a Circular Economy

Okon Recycling’s initiatives in rare metal recovery are vital to the circular economy movement. By reclaiming valuable materials from waste streams, the company helps close the loop in product lifecycles, reducing the demand for virgin resources and minimizing waste.

This approach benefits the environment and supports the long-term sustainability of industries reliant on rare metals. As global demand for these materials rises, particularly in renewable energy and advanced electronics, efficient recycling processes become increasingly important.

Through its innovative practices and commitment to sustainability, Okon Recycling demonstrates that effective rare metal recycling is both an environmental necessity and a viable business model. As the company refines its processes and expands its capabilities, it serves as a model for the future of sustainable resource management.

The Future of Sustainable Rare Metal Recycling

As technology advances, more innovative solutions are emerging. Cutting-edge techniques like AI-driven sorting systems and advanced chemical processes are already transforming the recycling landscape, promising greater efficiency and purity in recovered materials. These advancements are not just theoretical; they are being implemented by forward-thinking companies like Okon Recycling, leaders in this critical environmental and economic effort.

The implications of these developments extend beyond recycling. By reducing our reliance on primary mining, we conserve natural resources and significantly lower the carbon footprint associated with rare metal production. This ripple effect can play a vital role in global efforts to combat climate change and build a more sustainable future.

Looking ahead, sustainable rare metal recycling will play an increasingly pivotal role in our transition to a circular economy. This future is not something we can wait for; it is something we must actively create. Each of us can support and advance these initiatives through responsible consumption, supporting recycling programs, or advocating for policies that encourage sustainable practices. Our collective actions can drive meaningful change.

Partners like Okon Recycling are invaluable in this endeavor. Their expertise and commitment to innovation make them a trusted ally in the push for sustainable resource management. As we face the challenges and opportunities ahead, consider how you can contribute to this important cause. Together, we can build a future where rare metals are not just consumed but continually reborn through recycling. To learn more about participating in this sustainable effort, contact Okon Recycling at 214-717-4083.