5901 Botham Jean Blvd, Dallas, TX 75215

Unlocking Hidden Value with Specialty Metal Scrap Valuation Tools

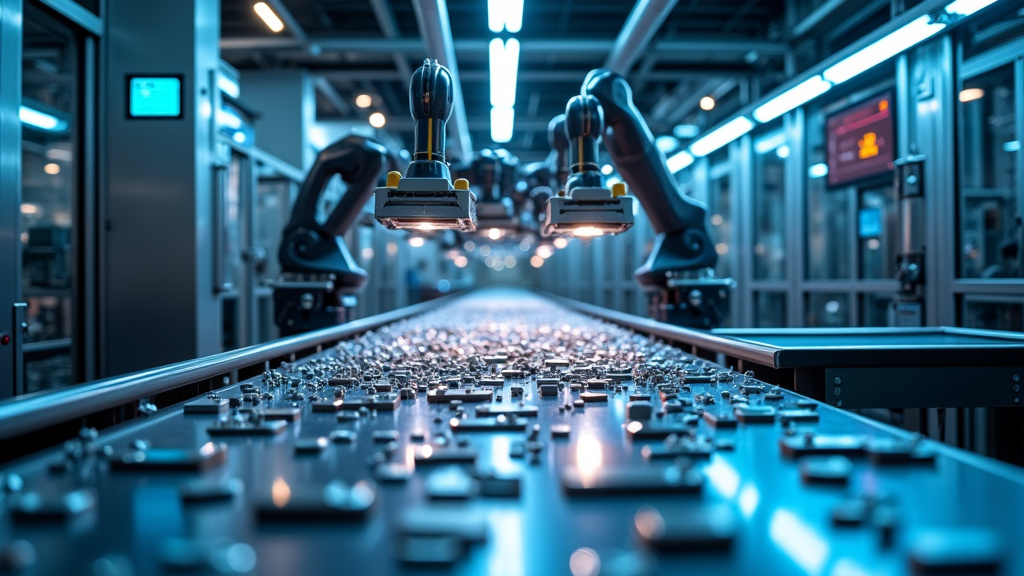

March 12, 2025What if the discarded metal components gathering dust in your facility held untapped potential? In recycling, specialty metal scrap valuation tools are transforming how we assess and extract value from rare and precious materials. These sophisticated instruments combine advanced technology with deep market insights to reveal hidden worth in what many might consider industrial waste.

The recycling industry faces a persistent challenge: accurately determining the true value of specialty metal scrap. Traditional methods often fall short when dealing with exotic alloys or trace elements, potentially leaving significant revenue unclaimed. This is where specialty metal scrap valuation tools come in, offering a groundbreaking approach to material assessment and pricing.

By leveraging advanced spectroscopic techniques and real-time market data, these tools provide recyclers with unprecedented accuracy in identifying and quantifying valuable metals within complex scrap streams. The result? Fair pricing for suppliers, optimized profits for recyclers, and a more efficient circular economy for rare and precious metals. But the impact of these tools extends beyond the balance sheet.

As natural resources become increasingly scarce, the ability to precisely recover and reuse specialty metals becomes more important. Innovative companies in the recycling sector are embracing these valuation tools not just to boost profitability, but as a critical component in building a more sustainable future for metal-intensive industries.

Types of Specialty Metal Scrap Valuation Tools

In the dynamic field of metal recycling, accurately valuing specialty metal scrap is vital for maximizing profits and ensuring fair transactions. The industry relies on advanced tools to analyze and determine the true worth of these valuable materials. Here are some key technologies enhancing precision in scrap metal valuation.

X-ray Fluorescence (XRF) Analyzers

XRF analyzers have transformed on-site metal identification and composition analysis. These portable devices emit X-rays to excite atoms in a sample, causing them to fluoresce and emit characteristic energy spectra. This non-destructive technique allows for rapid elemental analysis, making it invaluable for scrap yard operations.

An example is the Thermo Scientific Niton XL3t, which provides quick results for metal analysis, mining, and even consumer goods testing. Its portability and efficiency make it ideal for various applications, from scrap metal recycling to manufacturing quality control.

XRF analyzers excel in providing instant, on-the-spot analysis of metal alloys, allowing recyclers to quickly sort and grade incoming scrap. This technology is particularly useful for identifying valuable metals like gold, silver, and platinum group metals in mixed scrap loads.

Optical Emission Spectrometers (OES)

Optical Emission Spectrometry (OES) is another cornerstone in metal composition analysis. This technique involves exciting atoms in a sample using an electric arc or spark, then analyzing the light emitted to determine elemental composition. OES is effective for analyzing the full spectrum of elements in metal samples, from trace amounts to major components.

The SPECTROLAB S from SPECTRO Analytical Instruments is a prime example of a high-end OES analyzer. It offers exceptional accuracy and can analyze main alloying elements in under 12 seconds, making it ideal for high-throughput scrap processing facilities.

OES technology is excellent for detecting light elements like carbon, phosphorus, and sulfur, which are critical in determining the grade and value of steel alloys. This capability makes OES indispensable in foundries and steel mills where precise composition analysis is paramount.

Advanced Software Solutions

While hardware tools provide raw data, advanced software solutions are the brains behind modern scrap valuation. These platforms integrate data from various analytical instruments, market prices, and historical trends to provide comprehensive valuation insights.

Software solutions often incorporate artificial intelligence and machine learning algorithms to improve accuracy over time. They can factor in current market conditions, transportation costs, and even global economic indicators to provide a holistic view of scrap metal value.

Moreover, these software platforms frequently offer features like inventory management, customer relationship management, and compliance tracking, making them indispensable for modern recycling operations looking to streamline their processes and maximize profitability.

The Synergy of Tools in Scrap Valuation

The true power of specialty metal scrap valuation lies in the synergy between these tools. XRF analyzers provide rapid, on-site analysis, while OES offers deeper insights into metal composition. Advanced software then translates this data into actionable business intelligence.

By leveraging these technologies in concert, scrap metal recyclers can make informed decisions, optimize operations, and extract the maximum value from every piece of specialty metal scrap that passes through their yards. As the industry continues to evolve, we can expect these tools to become even more sophisticated, further refining the art and science of scrap metal valuation.

| Tool | Description |

|---|---|

| X-ray Fluorescence (XRF) Analyzers | Portable devices that provide rapid elemental analysis by emitting X-rays to excite atoms in a sample, useful for on-site metal identification. |

| Optical Emission Spectrometers (OES) | Instruments that use an electric arc or spark to excite atoms and analyze emitted light for detailed elemental composition, ideal for high-throughput facilities. |

| Advanced Software Solutions | Platforms integrating data from analytical instruments with market prices and trends, often using AI and machine learning for comprehensive valuation insights. |

Benefits of Using Advanced Valuation Tools in Metal Recycling

The metal recycling industry is undergoing significant technological advancements, with modern valuation tools transforming material assessment and processing. These innovative solutions offer numerous benefits that enhance the efficiency, profitability, and sustainability of recycling operations. Let’s examine the main advantages these tools provide.

Improved Material Assessment Accuracy

Advanced tools like X-ray fluorescence (XRF) analyzers and laser-induced breakdown spectroscopy (LIBS) devices have greatly improved the accuracy of material identification and grading. This precision is vital in an industry where material value can vary significantly based on composition.

These tools can detect trace elements and impurities often missed by traditional methods, allowing recyclers to accurately determine material value, ensuring fair pricing and optimal sorting for downstream processes.

Enhanced accuracy also helps identify high-value materials that might be overlooked. As McKinsey & Company notes, advanced recycling technologies can expand the types of plastics that are recyclable, producing materials suited for high-value applications.

Faster Processing Times

In the dynamic world of metal recycling, speed is crucial, and advanced valuation tools significantly improve processing times. Unlike traditional methods requiring lengthy laboratory analysis, these tools provide instant results, often in seconds.

This rapid assessment allows facilities to process larger material volumes quickly, reducing bottlenecks and increasing throughput. Faster processing also means quicker turnaround times for customers, improving service quality and potentially attracting more business.

The speed of these tools enables real-time decision-making on the recycling floor. Operators can quickly determine the best processing route for each batch, optimizing material flow through the facility.

Detection of Valuable Trace Elements

Advanced valuation tools can detect and quantify valuable trace elements in recycled materials, opening new revenue streams and increasing the value extracted from each batch of recycled metal.

These tools can identify small amounts of precious metals like gold, silver, or platinum in electronic waste, allowing for more effective recovery. They can also detect rare earth elements, increasingly in demand for high-tech applications.

This detailed analysis ensures recyclers can maximize material value, turning what might have been considered low-grade scrap into valuable commodities. As experts suggest, such value-added recycling services can increase profits by 30-50% compared to standard recycling.

Improved Quality Control

Advanced valuation tools enhance quality control processes within recycling facilities by providing accurate and consistent material assessments, ensuring output meets required specifications for downstream customers.

This improved quality control leads to several benefits:

- Higher customer satisfaction due to consistently high-quality recycled materials

- Reduced risk of contamination in recycled material batches

- Ability to meet stringent quality standards for specialized industries

- Fewer rejections and returns, leading to improved operational efficiency

- Enhanced reputation as a reliable supplier of high-quality recycled materials

Enhanced Profitability

The combination of increased accuracy, faster processing, and improved quality control directly translates to enhanced profitability for recycling operations. Advanced valuation tools allow recyclers to:

- Optimize pricing strategies based on precise material composition data

- Increase throughput without sacrificing quality

- Identify and capitalize on high-value materials more effectively

- Reduce operational costs through more efficient sorting and processing

- Minimize losses from misclassified or undervalued materials

Contribution to Sustainable Recycling Practices

Beyond economic benefits, advanced valuation tools promote more sustainable recycling practices. By enabling efficient and effective recycling processes, these tools help conserve resources and reduce the environmental impact of metal production.

Accurate material identification and sorting mean a higher percentage of recycled metals can be effectively recovered and reused, reducing the need for virgin material extraction, which is often energy-intensive and environmentally damaging.

The precision of these tools helps reduce waste and ensures materials are recycled to their highest potential use. This aligns with the principles of the circular economy, where resources are kept in use for as long as possible, extracting maximum value before responsible disposal.

In summary, advanced valuation tools are transforming the metal recycling industry, offering numerous benefits that enhance economic performance and environmental sustainability. As these technologies evolve, they will play an increasingly vital role in shaping future recycling practices worldwide.

| Trace Element | Source | Location |

|---|---|---|

| Cu | Soil, Air, Hair | Bangalore, India |

| Zn | Soil | Bangalore, India |

| Ag | Soil, Hair | Bangalore, India |

| Cd | Soil, Hair | Bangalore, India |

| In | Soil, Hair | Bangalore, India |

| Sn | Soil | Bangalore, India |

| Sb | Soil, Air, Hair | Bangalore, India |

| Hg | Soil, Air | Bangalore, India |

| Pb | Soil, Air, Hair | Bangalore, India |

| Bi | Soil, Air | Bangalore, India |

Challenges in Specialty Metal Scrap Valuation

Valuing specialty metal scrap is a complex task, even with advanced tools available to assist the process. Market volatility, intricate alloy compositions, and the constant need for calibration and training present significant challenges for recyclers and traders. Here, we explore these challenges and how expertise and current market knowledge are vital in overcoming them.

Market Volatility: Navigating Uncertainty

The specialty metals market is highly volatile, with prices fluctuating rapidly due to global economic shifts, geopolitical events, and supply chain disruptions. This volatility can significantly impact scrap valuation, as material values may change dramatically between collection and processing.

For example, the nickel market’s unprecedented price spike in March 2022 caused the London Metal Exchange to halt trading. Such events highlight the need for real-time market intelligence and agile pricing strategies in scrap valuation.

Recyclers now use sophisticated market analysis tools and maintain a global perspective to navigate these turbulent waters effectively. Some have adopted advanced monitoring systems that provide real-time data on market trends, enabling quicker decision-making and more accurate valuations.

Complex Alloy Compositions: The Challenge of Precise Valuation

Specialty metal scrap often consists of complex alloys, each with unique compositions that significantly affect their value. The challenge lies in accurately identifying and quantifying these compositions, especially with mixed or contaminated scrap loads.

Advanced spectrometry and X-ray fluorescence (XRF) technologies have improved composition analysis, but they are not infallible. Recyclers still face issues like surface contamination, which can skew readings, or deeply embedded materials that may go undetected.

Additionally, the growing use of rare earth elements and other critical materials in high-tech applications adds another layer of complexity. These elements, often present in minute quantities, can dramatically impact the scrap’s value but require specialized detection methods.

Ongoing Calibration and Training: The Human Factor

Even the most advanced valuation tools depend on their operators. The need for ongoing calibration of equipment and continuous training of personnel is a significant challenge in the industry. As new alloys enter the market and valuation technologies evolve, staying current is an ongoing process.

Recyclers must invest heavily in employee education and equipment maintenance to ensure accurate valuations. This includes regular software updates, sensor calibrations, and staff training sessions on the latest market trends and technological advancements.

Case Study: Innovation in Valuation

Consider GreenMetal Recycling, a mid-sized specialty metals recycler that faced declining profits due to valuation inaccuracies. The company implemented a multi-pronged approach to address these challenges:

- Invested in a state-of-the-art XRF analyzer with machine learning capabilities to improve alloy identification accuracy

- Developed proprietary software integrating real-time market data with composition analysis for dynamic pricing

- Partnered with a metallurgical laboratory for complex cases, ensuring precise valuation of rare or unusual alloys

- Implemented a rigorous training program, including quarterly workshops and certifications for all valuation staff

The results were transformative. Within a year, GreenMetal saw a 15% increase in valuation accuracy, leading to improved profit margins and stronger relationships with suppliers and buyers. Their success underscores the importance of combining technological innovation with human expertise and ongoing education.

In summary, while challenges in specialty metal scrap valuation persist, the path forward lies in embracing cutting-edge technologies, fostering expertise, and maintaining a commitment to continuous learning and adaptation. As the industry evolves, those who navigate these complexities with skill and innovation will lead in a crucial and dynamic market.

| Technology | Description | Advantages |

|---|---|---|

| XRF Analyzers | Portable devices that use X-rays to identify and analyze metal compositions. | Rapid, non-destructive analysis; ideal for sorting and grading metals on-site. |

| OES | Uses electric arc or spark to determine metal composition. | Effective for analyzing a full spectrum of elements, including light elements. |

| Advanced Software | Integrates data from analytical instruments with market data. | Provides comprehensive valuation insights and improves accuracy over time. |

How Okon Recycling Can Help with Specialty Metal Scrap Valuation Tools

In the dynamic field of metal recycling, precise valuation of specialty scrap is crucial for a business’s success. Okon Recycling leads this challenge with advanced tools that turn complex specialty metal scrap valuation into a precise science.

With over a century of experience, Okon Recycling combines time-tested expertise with modern innovation. This blend allows us to confidently handle intricate metal alloys, ensuring our clients receive fair and competitive pricing.

What sets Okon apart in recycling services? Our unwavering commitment to customization. We understand that no two businesses are alike, especially in the diverse industrial landscape of the DFW area and beyond. That’s why we’ve developed a suite of tailored recycling solutions to meet each client’s unique needs.

State-of-the-Art Valuation Technology

At the core of Okon’s specialty metal scrap valuation process is a sophisticated array of technological tools. These include advanced spectrometers, X-ray fluorescence analyzers, and proprietary software systems that identify and assess material value with pinpoint accuracy.

This high-tech approach allows us to quickly determine the composition of complex alloys, separating valuable components from less desirable elements. For our clients, this means maximized returns on their scrap metal and unmatched pricing transparency.

| Technology | Description | Application |

| X-ray Fluorescence (XRF) Analyzers | Non-destructive elemental analysis using X-rays | Identifying and grading metal alloys, detecting hazardous materials |

| Laser Induced Breakdown Spectroscopy (LIBS) | Uses laser to analyze chemical composition | Sorting low alloy/carbon steels, identifying carbon content |

| Advanced Software Solutions | Integrates data from instruments and market trends | Comprehensive valuation insights, inventory management |

| Radiation Monitoring and Detection | Detects and monitors radiation levels | Preventing contaminated scrap from entering supply stream |

| Artificial Intelligence | Predicts market trends using large data sets | Optimizing production and inventory management |

| Blockchain | Ensures traceability and authenticity of materials | Recording transactions and verifying recycled metal information |

| Drones | Uses LiDAR technology for inventory management | Creating 3D models of stockpiles, monitoring safety hazards |

However, technology alone isn’t enough. It’s the expertise of our team that truly brings these tools to life. Our technicians undergo rigorous training to master these systems, ensuring every valuation is backed by cutting-edge tech and human expertise.

Customized Solutions for Every Client

In specialty metal recycling, one size doesn’t fit all. That’s why Okon Recycling has developed a flexible approach that adapts to the unique challenges of each client. Whether you’re a small machine shop or a large-scale industrial operation, we have a tailored solution for you.

Our customized services might include on-site collection, specialized sorting processes, or dedicated recycling programs integrated into your production workflow. We work closely with clients to understand their needs, industry regulations, and operational constraints, crafting a recycling solution that fits seamlessly into their business model.

This customization extends to our pricing structures as well. We understand that market fluctuations impact the value of specialty metals. Our dynamic pricing models, supported by real-time market data, ensure our clients always receive competitive rates for their materials.

The Okon Advantage: Experience Meets Innovation

What truly sets Okon Recycling apart is our unique position at the intersection of long-standing industry experience and cutting-edge innovation. Our century of operation has provided us with an unparalleled understanding of the metal recycling landscape, including its trends and the factors that influence material values.

This deep knowledge forms the foundation for our modern approach. By combining time-tested insights with the latest technological advancements, we offer a level of service that’s truly best-in-class. Our clients benefit from solutions that are effective today and adaptable to tomorrow’s challenges.

In an industry where precision can mean the difference between profit and loss, Okon Recycling’s specialty metal scrap valuation tools provide a clear competitive edge. We invite businesses across the DFW area and beyond to experience the Okon difference—where a century of expertise meets the future of recycling technology, all in service of maximizing value for our clients.

The Future of Specialty Metal Scrap Valuation

As these technologies continue to evolve and integrate, the future of specialty metal scrap valuation looks promising. Recyclers who embrace these innovations will be better equipped to navigate market fluctuations, reduce operational costs, and contribute to a more sustainable, circular economy for metals.

In this rapidly changing environment, partnering with a forward-thinking recycling company is more crucial than ever. Okon Recycling is committed to staying at the forefront of technological advancements, ensuring our clients receive the best value for their specialty metal scrap while contributing to a cleaner, more sustainable future. By choosing an innovative partner like Okon Recycling, businesses can not only maximize their returns but also play a vital role in shaping a more resource-efficient world.

As we look to the future, the long-term benefits of working with a technologically advanced recycling partner become increasingly clear. From more accurate valuations to improved environmental outcomes, the advantages extend far beyond immediate financial gains. We invite you to consider the positive impact you can make by choosing a recycling partner dedicated to innovation and sustainability.

Contact Okon Recycling at 214-717-4083 to learn more about how our cutting-edge approach to specialty metal scrap valuation can benefit your business and contribute to a brighter, more sustainable future for our planet.