5901 Botham Jean Blvd, Dallas, TX 75215

Top Specialty Metal Recyclers for High-Demand Materials

March 7, 2025In a world of dwindling natural resources and growing environmental concerns, specialty metal recyclers play a vital role in sustainability. These firms ensure that valuable metals like gold, silver, platinum, and rare earth elements are efficiently processed and reintroduced into the supply chain, rather than ending up in landfills.

For businesses and individuals looking to recycle specialty metals in Texas, particularly in the Dallas-Fort Worth (DFW) area, Okon Recycling stands out as a trusted facility. With a strong commitment to efficient metal recovery and environmental responsibility, Okon Recycling provides a reliable solution for those looking to dispose of specialty metals responsibly while maximizing their value.

Specialty metal recycling is not just about waste reduction; it’s a crucial component of the circular economy, ensuring that precious and industrial metals remain in continuous use. Whether you’re dealing with electronic scrap, industrial alloys, or catalytic converters, knowing where to recycle ensures that these valuable materials are processed efficiently and sustainably.

By choosing reputable recyclers like Okon Recycling, individuals and businesses can contribute to resource conservation, energy savings, and a cleaner environment.

Maximizing the Value: How Specialty Metal Recyclers Enhance Efficiency

Specialty metal recyclers are leading innovation in resource management, using advanced technologies to transform recycling processes. These techniques not only improve efficiency but also enhance cost-effectiveness, marking a new era in sustainable metal recovery.

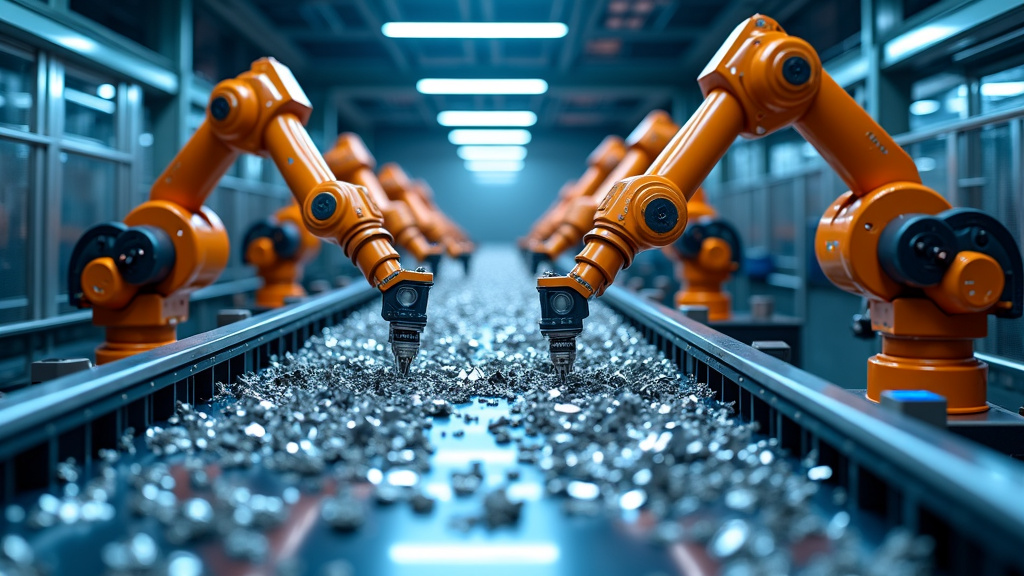

A key advancement has been the use of automated sorting systems. These systems, which employ sensors, robotics, and AI, accurately identify and separate different metals. Industry experts note that technologies like X-ray fluorescence (XRF) and electromagnetic sensors can detect metal compositions in mixed scrap streams with high precision.

The impact on efficiency is significant. By eliminating manual sorting, recyclers process more scrap in less time, increasing throughput. Moreover, the accuracy of these systems ensures higher purity of sorted materials, leading to better market prices and new applications for recycled metals.

Metal Analysis: A Key Innovation in Recycling

Alongside automated sorting, advanced metal analysis techniques are crucial for specialty recyclers. These methods offer real-time, detailed examinations of metal composition, allowing informed decisions for processing and maximizing material value.

Laser-Induced Breakdown Spectroscopy (LIBS) is a groundbreaking technology. It uses lasers to analyze metal surfaces, providing instant feedback on composition. The speed and accuracy of LIBS allow for rapid identification and sorting of complex alloys that were previously difficult to recycle efficiently.

Handheld XRF analyzers are another innovation. These devices enable on-site analysis, quickly determining scrap metal composition and value. This immediate insight aids strategic decisions about purchasing, processing, and selling recycled materials, ultimately boosting profitability.

Improving Cost-Effectiveness with Technology

Adopting these technologies requires significant upfront investment. However, the long-term benefits in operational efficiency and cost-effectiveness are substantial. By reducing labor costs, minimizing errors, and speeding up processing, these technologies often pay for themselves quickly.

The ability to recover more valuable metals from complex scrap sources has opened new revenue streams. For example, recovering rare earth elements from electronic waste has become economically viable, adding value to materials that might have been overlooked.

These efficiency improvements also offer environmental benefits. Maximizing metal recovery reduces landfill waste and the demand for environmentally costly virgin ore extraction, aligning with global circular economy principles and sustainable resource management.

The Future of Metal Recycling

As technology advances, the future of specialty metal recycling looks promising. Emerging technologies like machine learning and advanced data analytics promise to further optimize recycling processes, predicting market trends and automating complex decision-making tasks.

The integration of these technologies is not just changing the recycling industry; it is reshaping global resource management. By making metal recycling more efficient and cost-effective, these innovations pave the way for a more sustainable future.

The combination of advanced recycling technologies and sophisticated metal analysis has ushered in a new era of efficiency and value creation in the specialty metal recycling industry. As these technologies evolve, they will play a crucial role in meeting the growing demand for metals while minimizing environmental impact.

| Technique | Primary Purpose | Input Material | Energy Efficiency | Applications |

|---|---|---|---|---|

| Electrolysis | Decomposing compounds, refining metals | Ionic compounds | Higher energy consumption per kg of material | Broad applications including metal refining |

| Electrowinning | Recovering metals from solutions | Metal-rich solutions | More energy-efficient per kg of metal | Recovery from leach solutions with high efficiency |

The Role of Specialty Metal Recyclers in the Circular Economy

Specialty metal recyclers are pivotal in advancing the circular economy. These facilities handle the complex task of reclaiming valuable metals from various products and industrial waste streams.

By diverting metals from landfills and reintroducing them into production cycles, recyclers conserve finite natural resources and reduce the environmental impact of mining. This process is crucial for fostering a more sustainable and resource-efficient economy.

The circular economy aims to eliminate waste by designing products and systems that keep materials in use indefinitely. Specialty metal recyclers are key in closing the loop for valuable metals like copper, aluminum, and rare earth elements.

Minimizing Waste and Conserving Resources

Specialty metal recycling significantly reduces waste. By reclaiming metals from end-of-life products and industrial scrap, recyclers prevent these valuable materials from ending up in landfills.

This not only conserves landfill space but also preserves the embedded energy and resources used in extracting and refining these metals. Recycling steel, for example, can be 100% efficient, with both pre-consumer and post-consumer scrap being fully recyclable.

Resource conservation is another critical aspect of specialty metal recycling. By providing a steady stream of recycled materials, these facilities reduce the demand for virgin ore extraction, which often involves destructive mining practices and habitat disruption.

This effort is especially important for rare and precious metals used in electronics and green technologies. Recycling these materials ensures a more stable supply chain and reduces geopolitical tensions over access to limited mineral deposits.

Moreover, recycling typically requires significantly less energy compared to primary metal production. For instance, recycling aluminum uses only about 5% of the energy needed to produce new aluminum from bauxite ore.

Reducing Environmental Impact

The environmental benefits of specialty metal recycling extend beyond waste reduction. By decreasing the need for primary metal production, recyclers help reduce greenhouse gas emissions associated with mining and refining operations.

Metal recycling also prevents the release of toxic substances into the environment. Many electronic devices contain hazardous materials that can leach into soil and water if not handled properly. Specialty recyclers use advanced techniques to safely recover valuable metals while properly disposing of harmful components.

Water conservation is another important environmental benefit. Mining and ore processing are typically water-intensive activities, often competing with local communities and ecosystems for scarce water resources. Recycling metals significantly reduces the water footprint of metal production.

Additionally, recycling helps preserve biodiversity by reducing the need for new mining operations, which often involve clearing large areas of land and disrupting local ecosystems. This is crucial in ecologically sensitive areas rich in mineral deposits.

Promoting Responsible Resource Use

Specialty metal recyclers promote more responsible resource use across industries. By providing a reliable source of recycled materials, they enable manufacturers to reduce reliance on virgin resources and adopt more sustainable production practices.

This shift towards recycled materials encourages companies to design products with recyclability in mind, creating a positive feedback loop that enhances the circular economy. Many industries are now setting ambitious targets for incorporating recycled content into their products.

The recycling industry also drives innovation in material science and recycling technologies. As demand for recycled metals grows, recyclers develop more efficient methods for recovering materials from complex products like electronics and vehicles.

Moreover, the specialty metal recycling sector creates green jobs and contributes to local economies. These facilities often serve as hubs for community recycling efforts, raising awareness about the importance of responsible waste management and resource conservation.

Challenges and Future Outlook

Despite its benefits, the specialty metal recycling industry faces several challenges. One major issue is the complexity of modern products, which often contain intricate mixtures of materials that can be difficult to separate and recycle efficiently.

Another challenge is the need for better collection and sorting systems to ensure a steady supply of recyclable materials. Improving consumer awareness and participation in recycling programs is crucial for maximizing the potential of metal recycling.

Looking ahead, the role of specialty metal recyclers in the circular economy is set to grow even more important. As the world transitions towards renewable energy and electric vehicles, demand for specialty metals will increase dramatically.

Recyclers will play a critical role in meeting this demand sustainably, helping to create a more resilient and environmentally friendly supply chain for these essential materials. Their continued innovation and expansion will be key to realizing the full potential of the circular economy.

In summary, specialty metal recyclers are essential partners in building a more sustainable and resource-efficient future. By minimizing waste, conserving resources, and promoting responsible material use, they are helping to transform our linear economy into a circular one that thrives within planetary boundaries.

| Metal | Primary Production Energy Use | Recycling Energy Use | Energy Savings in Recycling |

|---|---|---|---|

| Aluminium | 14,000 kWh/tonne | 5% of primary | 95% |

| Steel | 20,000 kWh/tonne | 25% of primary | 75% |

AI and Automation: Transforming Specialty Metal Recycling

The metal recycling industry is experiencing a major transformation, with AI-driven technologies and automation leading the way. These innovations are enhancing how we sort and process specialty metals, significantly improving accuracy and safety.

Manual sorting and error-prone processes are becoming a thing of the past. Today’s recycling facilities increasingly resemble high-tech laboratories, where sophisticated AI systems and robotic arms work together to maximize efficiency.

A key advancement in this field is the use of machine learning algorithms for metal identification. These systems can instantly analyze the composition of different metals, ensuring precise sorting even for complex alloys.

Enhancing Sorting Accuracy with AI

AI-powered sorting systems are revolutionizing the specialty metal recycling sector. Using advanced computer vision and spectral analysis, these systems can identify and categorize metals with exceptional accuracy.

For example, robotic arms equipped with AI can now distinguish between different grades of aluminum, copper, and other valuable metals in milliseconds. This level of precision was unimaginable just a few years ago.

Moreover, these AI systems continuously learn and improve their accuracy over time. By analyzing millions of samples, they become increasingly adept at identifying even the most challenging metal compositions.

The impact on recovery rates has been remarkable. Recycling facilities using AI-driven sorting report recovery rate improvements of up to 20%, a significant boost in an industry where margins can be tight.

It’s not just about quantity – the quality of recovered metals has also improved. By reducing contamination and ensuring purer sorted streams, AI systems help produce higher-grade recycled metals suitable for more applications.

Optimizing Process Efficiency Through Automation

Automation is another crucial factor in transforming specialty metal recycling. From conveyor systems to robotic handlers, automated processes streamline operations and boost productivity.

One impressive application of automation is in metal shredding and separation. Advanced shredders equipped with sensors can automatically adjust their operation based on the input material, ensuring optimal processing for different metal types.

Automated systems also excel at handling hazardous materials, significantly improving worker safety. Robots can now tackle tasks that were once dangerous for human workers, such as sorting electronic waste containing toxic elements.

Furthermore, automation plays a crucial role in data collection and analysis. Integrated systems track every step of the recycling process, providing valuable insights for further operational optimization.

The combination of AI and automation also enables 24/7 operation in many facilities. This continuous processing capability dramatically increases throughput and efficiency in the industry.

The Future of AI and Automation in Metal Recycling

Looking ahead, the potential for AI and automation in specialty metal recycling seems limitless. Experts predict that these technologies will continue to evolve, bringing even greater efficiencies to the industry.

One exciting development is the use of AI for predictive maintenance. By analyzing operational data, AI systems can forecast equipment failures, allowing for proactive maintenance and minimizing costly downtime.

Another promising trend is the integration of blockchain technology with AI-driven recycling systems. This combination could create transparent, traceable supply chains for recycled metals, boosting confidence in the quality and origin of recycled materials.

We are also likely to see more sophisticated AI algorithms that can adapt to changing market conditions. These systems could automatically adjust sorting priorities based on real-time metal prices, maximizing the economic value of recycled materials.

As these technologies advance, we can expect higher recovery rates, improved metal purity, and more efficient operations across the industry. The future of specialty metal recycling is undoubtedly bright, powered by the unstoppable force of AI and automation.

Okon Recycling: A Trusted Hub for Specialty Metal Recycling in Texas

Finding a reliable specialty metal recycler is essential for ensuring that valuable materials are

processed efficiently and sustainably. In Dallas, Fort Worth, and the broader DFW area,

Okon Recycling stands out as a premier facility for handling specialty and high-value metals,

including nickel alloys, stainless steel, platinum, palladium, gold, silver, and electronic scrap.

Why Choose Okon Recycling for Specialty Metals?

Specialty metals require precise handling and advanced processing techniques to

maximize recovery rates and maintain metal purity. Okon Recycling offers:

- Expertise in processing high-value metals such as platinum, gold, and rare earth elements

- Advanced sorting and refining technologies to extract the highest metal yield with minimal waste

- Sustainable recycling methods that reduce landfill waste and minimize environmental impact

- Competitive market pricing to ensure you get the best value for your recycled materials

- A convenient location in the DFW area, making it easy for businesses and individuals to drop off specialty metals

Industries That Benefit from Specialty Metal Recycling at Okon Recycling

Businesses and industries that frequently work with specialty metals can greatly benefit from

partnering with Okon Recycling. These include:

- Electronics manufacturers and recyclers handling circuit boards, computer components, and high-tech scrap

- Aerospace and automotive industries needing to recycle nickel, titanium, and cobalt alloys

- Medical equipment suppliers with precious metal-containing materials such as platinum and silver-coated components

- Industrial and construction firms managing high-grade stainless steel, tungsten, and rare alloys

Sustainability and Circular Economy Commitment

By working with Okon Recycling, businesses and individuals actively contribute to the

circular economy, ensuring that specialty metals remain in continuous use rather than being

lost to landfills. Their state-of-the-art facility in Texas is committed to environmentally responsible

recycling, making it a trusted name in metal recovery.

For those in Dallas, Fort Worth, and surrounding areas, Okon Recycling provides an efficient

and responsible way to recycle specialty metals while ensuring fair pricing and sustainable processing.

Conclusion: Towards a More Sustainable Future with Specialty Metal Recycling

As industries continue to shift towards sustainable resource management, specialty metal recycling plays a crucial role in reducing waste, conserving natural resources, and lowering environmental impact. The shift from traditional mining to recovering valuable metals from discarded materials is not just an environmental necessity—it’s an economic and industrial imperative.

For those in Dallas, Fort Worth, and across Texas, Okon Recycling provides a dedicated and environmentally responsible solution for processing specialty metals. By leveraging advanced recycling technologies and prioritizing sustainability, they ensure that materials once considered “waste” are recovered, refined, and reused.

The future of metal recycling will continue to evolve with advancements in AI-driven sorting, automated processing, and green technologies. As demand for specialty metals grows—particularly in the electronics, automotive, and energy sectors—responsible recycling practices will become even more critical.

By choosing the right recycling partner, such as Okon Recycling, businesses and individuals can actively participate in the circular economy while ensuring their materials are processed efficiently and ethically. In the end, every recycled metal contributes to a cleaner planet, a more sustainable economy, and a smarter way to manage our valuable resources.

To explore how you can contribute to a cleaner, more sustainable future through metal recycling, contact Okon Recycling at 214-736-9509.