5901 Botham Jean Blvd, Dallas, TX 75215

Exploring Innovative Specialty Metal Recycling Programs

February 21, 2025The field of metal recycling is undergoing significant changes, driven by cutting-edge technologies and increased environmental awareness. Advanced automated sorting systems, powered by artificial intelligence and machine learning, are enhancing the efficiency and accuracy of metal separation.

These systems can identify and sort diverse metal types with remarkable precision, reducing contamination and improving the quality of recycled materials.

At the same time, state-of-the-art shredding technologies are expanding the possibilities in metal recycling. Modern shredders can process complex metal assemblies, including electronic waste, with impressive speed and efficiency. This capability is essential as we aim to recover valuable metals from increasingly intricate products and devices. Effectively recycling specialty metals not only conserves finite resources but also reduces the environmental impact of mining and raw material extraction.

The benefits of these innovative recycling programs extend beyond environmental conservation. By improving the efficiency of metal recycling, these technologies create a powerful synergy between environmental sustainability and economic viability. Studies have shown that metal recycling can reduce greenhouse gas emissions by up to 90% compared to primary metal production, while also conserving valuable natural resources.

Economically, developing and implementing advanced recycling technologies foster innovation and create new job opportunities in the green technology sector. As these programs expand, they have the potential to reduce production costs for industries reliant on specialty metals, enhancing competitiveness and driving economic growth.

Technologies Revolutionizing Specialty Metal Recycling

The recycling industry is experiencing a significant transformation, driven by advanced technologies reshaping metal processing and recovery. Two key innovations – AI-driven sorting systems and advanced hydrometallurgical processes – are leading this change, offering exceptional efficiency and environmental advantages in specialty metal recycling.

AI-Powered Sorting: Precision and Efficiency in Metal Recovery

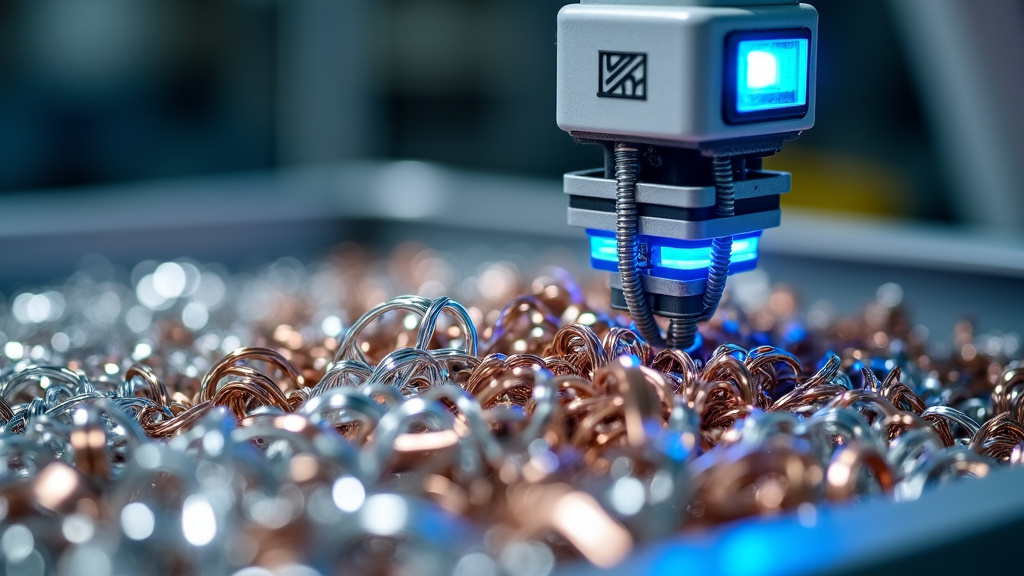

Artificial intelligence significantly enhances the accuracy and speed of metal sorting. These systems use machine learning algorithms and computer vision to identify and categorize various metals with impressive precision.

One example is the ZenRobotics Heavy Picker, an AI-driven robotic system designed for metal recycling. This technology uses advanced sensors and machine learning to quickly identify and sort different metals, greatly improving recycling operations.

The benefits of AI-powered sorting are considerable. These systems process large volumes of scrap metal faster than traditional methods, increasing throughput and reducing labor costs. Additionally, the improved accuracy minimizes contamination, resulting in higher-quality recycled materials that fetch better market prices.

Hydrometallurgical Processes: A Cleaner Path to Metal Recovery

Alongside AI, advanced hydrometallurgical processes are changing how we extract and purify metals from recycled materials. These chemical-based methods offer a more environmentally friendly alternative to traditional high-temperature smelting techniques.

A notable example is the process developed for recycling spent automotive lithium-ion batteries. This method efficiently recovers high-grade graphite, cathode metal salts, and lithium carbonate, highlighting the potential for comprehensive material recovery.

Hydrometallurgical processes typically involve leaching metals into a solution, followed by selective extraction and purification steps. These techniques allow for recovering a broader range of metals, including rare earth elements, crucial for many high-tech applications.

The Synergy of AI and Hydrometallurgy

When combined, AI-driven sorting and advanced hydrometallurgical processes create a powerful synergy. AI ensures that only the most suitable materials enter the hydrometallurgical treatment, optimizing the efficiency of chemical processes and reducing waste.

This integration leads to several key benefits:

- Increased metal recovery rates, often exceeding 95% for key elements

- Reduced energy consumption compared to traditional recycling methods

- Lower environmental impact due to decreased emissions and chemical usage

- Enhanced ability to recover critical and rare earth metals

- Improved economic viability of recycling operations

| Technology | Benefits |

| AI-Powered Sorting | Increases throughput and reduces labor costs; enhances accuracy to minimize contamination; results in higher-quality recycled materials |

| Hydrometallurgical Processes | Offers environmentally friendly metal extraction; recovers a wide range of metals including rare earth elements; reduces energy consumption |

The Future of Metal Recycling

As these technologies continue to evolve, we can expect even greater advancements in metal recycling efficiency. Future developments may include:

- More sophisticated AI algorithms capable of identifying complex alloys and composites

- Novel hydrometallurgical processes that further reduce environmental impact

- Integration of these technologies into smaller, more accessible recycling systems

- Increased focus on recovering critical metals essential for renewable energy and electric vehicle technologies

The revolution in specialty metal recycling, driven by AI and advanced hydrometallurgy, is not just transforming an industry – it is paving the way for a more sustainable and resource-efficient future. As these technologies become more widespread, they will play a crucial role in meeting the growing global demand for metals while minimizing environmental impact.

Strategies for Effective Metal Recycling Programs

In the environmentally conscious business world, robust metal recycling programs are crucial for sustainable operations. By adopting strategic approaches, companies can enhance waste management efficiency while achieving broader sustainability goals. Here are some key strategies for creating effective metal recycling initiatives.

Implementing Dedicated Metal Collection Bins

Installing dedicated metal collection bins throughout facilities is an impactful step. These bins serve as convenient points for employees to dispose of recyclable metals. By placing these containers in high-traffic areas, companies can increase participation rates in their recycling programs.

For optimal results, consider color-coding bins or using clear signage to indicate which types of metals should be deposited. For example, use blue bins for aluminum cans, red for copper wiring, and green for steel scrap. This visual system makes it easier for staff to sort metals correctly, reducing contamination and improving the quality of collected materials.

Additionally, implementing a system to regularly empty and maintain these bins ensures they remain accessible and hygienic. This upkeep promotes continued use and demonstrates the company’s commitment to the recycling program.

Conducting Comprehensive Recycling Audits

Regular recycling audits are essential for identifying areas of improvement and tracking the progress of your metal recycling initiatives. These assessments provide insights into the types and quantities of metals being recycled, highlighting any inefficiencies in the collection process.

To conduct an effective audit, start by analyzing the contents of your metal recycling bins over a set period. Document the various types of metals collected, their weights, and any non-metallic contaminants found. This data helps you understand your company’s recycling patterns and pinpoint opportunities for enhancement.

Audits can also reveal whether employees are correctly sorting metals and following recycling guidelines. Use these findings to refine educational programs and adjust bin placement if necessary. The EPA offers guidelines on conducting waste assessments, which can be adapted for metal recycling audits.

Forging Partnerships with Local Recyclers

Collaborating with local recycling facilities can boost the effectiveness of your metal recycling program. These partnerships provide businesses with expert guidance on best practices and ensure that collected metals are processed efficiently and responsibly.

When seeking a recycling partner, look for facilities specializing in the types of metals your business generates. Many recyclers offer pickup services, streamlining your collection process and reducing transportation costs. Some partners may provide detailed reports on recycled materials, helping you track your program’s impact and identify areas for improvement.

Consider reaching out to industry associations or local environmental agencies for recommendations on reputable recycling partners in your area. Building a strong relationship with a trusted recycler can lead to long-term benefits, including potential revenue from valuable scrap metals and enhanced corporate sustainability credentials.

Educating and Engaging Employees

The success of any metal recycling program hinges on employee participation. Developing a comprehensive education and engagement strategy is crucial for fostering a culture of recycling within your organization. Conduct training sessions that explain the importance of metal recycling and provide clear instructions on proper sorting techniques.

Create informative posters or digital displays near recycling stations as quick reference guides. Consider implementing a rewards system to incentivize participation, such as recognizing top recyclers or departments that show significant improvement in recycling rates.

Regularly communicate the progress and impact of your recycling efforts to keep employees motivated. Share success stories, like the amount of metal diverted from landfills or the environmental benefits achieved through recycling. This transparency helps employees see the tangible results of their efforts and reinforces the importance of their participation.

Leveraging Technology for Efficient Tracking

Incorporating technology into your metal recycling program can streamline data collection and analysis, making it easier to monitor progress and identify areas for improvement. Consider implementing software solutions that allow for real-time tracking of recycled materials, generate reports on recycling rates, and forecast future trends.

Some advanced systems use sensors in collection bins to alert facility managers when containers are nearing capacity, optimizing pickup schedules and preventing overflow. By leveraging these technological tools, businesses can make data-driven decisions to refine and enhance their recycling strategies continually.

As we move toward a more sustainable future, effective metal recycling programs are becoming increasingly vital for businesses across all industries. By implementing dedicated collection bins, conducting regular audits, partnering with local recyclers, engaging employees, and leveraging technology, companies can create robust recycling initiatives that benefit the environment and contribute to their bottom line.

Remember, every small step toward better metal recycling practices can have a significant cumulative impact. Start by assessing your current recycling efforts and identifying areas where you can implement these strategies. With commitment and consistent effort, your business can become a leader in sustainable waste management, setting an example for others to follow.

The Role of Innovative Recycling in Sustainability

The metal recycling industry leads sustainable innovation, advancing the circular economy with groundbreaking technologies. By allowing metals to be reused without losing quality, these advancements are reshaping resource management and industrial sustainability.

Central to this transformation is the circular economy concept. Unlike traditional linear models of production and disposal, the circular approach keeps valuable materials in use for as long as possible. Innovative recycling technologies are crucial in this shift, enabling efficient recovery and reprocessing of metals.

One significant impact of these innovations is the reduced need for new material extraction. By maximizing the reuse of existing metals, we can substantially decrease the environmental footprint of mining and refining virgin materials. This conserves natural resources and minimizes habitat disruption and biodiversity loss in mining regions.

Cutting-Edge Technologies Driving Change

Artificial intelligence and machine learning are transforming the sorting process in metal recycling facilities. These advanced systems identify and separate different types of metals with unprecedented accuracy, improving recycling rates and reducing contamination. The result is higher quality recycled materials that can replace virgin metals in manufacturing processes.

Another groundbreaking innovation is the development of advanced metallurgical processes to recover valuable metals from complex waste streams. Techniques such as bioleaching and electrochemical extraction are opening up new sources of recycled materials that were previously too difficult or expensive to process.

Closed-loop manufacturing systems are also gaining traction, with many metal producers implementing in-house recycling facilities. This approach minimizes waste generation and reduces transportation costs and emissions associated with off-site recycling.

Environmental and Economic Benefits

The environmental benefits of innovative metal recycling are substantial. By reducing the need for primary metal production, these technologies help lower greenhouse gas emissions, conserve energy, and minimize water pollution associated with traditional mining and refining processes.

Economically, advancements in metal recycling create new opportunities and efficiencies. As recycling processes become more sophisticated and cost-effective, the market for recycled metals grows, driving further innovation and investment in the sector.

Moreover, the shift towards a more circular economy in metal usage enhances resource security and reduces dependence on volatile raw material markets. This stability positively impacts industries ranging from construction to electronics manufacturing.

Looking to the Future

The potential for further innovation in metal recycling is immense. Emerging technologies like 3D printing with recycled metal powders and blockchain-based material traceability systems promise to further enhance the efficiency and transparency of recycling processes.

The journey towards a fully sustainable metal industry is ongoing, but the progress through innovative recycling technologies is undeniable. By continuing to invest in research and development and fostering collaboration between industry, government, and academia, we can accelerate the transition to a truly circular economy for metals.

In conclusion, innovative recycling is not just about managing waste—it’s about reimagining our approach to resource use and industrial production. As these technologies evolve, they will play an increasingly vital role in building a more sustainable and resilient future for generations to come.

| Process | Energy Use | GHG Emissions Reduction | Natural Resource Conservation |

| Primary Metal Production | High (7-8% of global energy use) | None | None |

| Metal Recycling | Low (up to 95% energy savings for aluminum) | Up to 90% reduction | Significant (reduces need for mining) |

Embracing Innovation in Metal Recycling

Innovative specialty metal recycling programs are essential in building a sustainable future. These initiatives represent a shift in how we view and handle our resources, transforming what was once considered waste into valuable materials that fuel both environmental protection and economic growth.

Companies like Okon Recycling lead this green revolution, exemplifying a commitment to efficient, eco-friendly solutions. Their approach goes beyond mere recycling; it’s about reimagining the entire lifecycle of metals in our society. By implementing advanced technologies and sustainable practices, Okon Recycling sets new standards for the industry and paves the way for a circular economy.

The impact of these recycling programs extends beyond immediate environmental benefits. They play a crucial role in advancing both environmental and economic well-being. By reducing the need for raw material extraction, these programs help conserve natural resources, minimize energy consumption, and significantly cut greenhouse gas emissions. Studies have shown that recycling metals can save up to 95% of the energy required to produce new metals from raw materials, demonstrating the potential for positive environmental impact.

Moreover, the economic benefits of these recycling programs are impressive. They create jobs across various sectors, from collection and processing to manufacturing and sales. The metal recycling industry contributes billions to the global economy annually, fostering local economic growth and providing sustainable employment opportunities. This dual benefit of environmental protection and economic stimulation makes embracing recycling innovations not just a choice, but a necessity for our collective future.

Final Words

The future of metal recycling hinges on innovation and widespread adoption of sustainable practices. As resource scarcity and climate change intensify, bold solutions and collective action are essential. Businesses, governments, and individuals must recognize the transformative power of metal recycling and take decisive steps toward a greener future.

Now is the time to act. Whether you’re a business owner optimizing waste management or an individual making eco-conscious choices, you can support sustainable recycling. Research local initiatives, educate others, and actively participate in metal recycling efforts.

Every piece of metal recycled brings us closer to a circular economy. By partnering with Okon Recycling, you reduce waste, conserve resources, and invest in a cleaner future.

Join the movement today. Contact Okon Recycling at 214-736-9509 to explore sustainable metal recycling solutions and make a lasting impact. Together, we can shape a more sustainable world.