5901 Botham Jean Blvd, Dallas, TX 75215

Rare Metal Lifecycle Management Solutions

February 20, 2025Have you ever wondered what happens to your old smartphone or electric car battery when you’re done with it? The answer lies in the fascinating world of rare metal lifecycle management—a critical yet often overlooked aspect of modern technological society.

Rare metals, despite their name, are not necessarily scarce in nature. However, their extraction and processing pose significant environmental and economic challenges. As our demand for advanced electronics and sustainable transportation grows, so does the urgency to manage these valuable resources responsibly.

Industries like electronics and automotive heavily rely on rare metals for their advanced products. Consider neodymium in your smartphone’s vibration motor or lithium in electric vehicle batteries. The increasing demand for these metals has led to a global resource management shift, with companies developing innovative solutions.

Enter firms like Okon Recycling, pioneers in rare metal recycling. These sustainability leaders are reshaping how we view the lifecycle of our gadgets and vehicles. Their advanced techniques not only recover precious materials—they’re redefining the concept of waste itself.

Enhancing Recycling Processes for Rare Metals

As global demand for rare metals surges, innovative recycling technologies have become essential for conserving resources and protecting the environment. These advanced methods are transforming how industries recover and reuse valuable materials, paving the way for a more sustainable and efficient future.

One promising development in this field is the use of hydrometallurgical processes. Unlike traditional high-temperature smelting, these techniques use water-based chemistry to extract metals at lower temperatures. Recent advancements in hydrometallurgy have significantly improved the efficiency and selectivity of metal recovery, especially for complex and low-grade ores.

Electrochemical recycling methods are also gaining traction. These processes use electric currents to dissolve and separate metals from waste, allowing precise control over metal purity and composition. The development of improved electrode materials and cell designs has made electrochemical recycling viable for a wider range of metals.

Advanced Sorting Technologies

Effective sorting is crucial for successful rare metal recycling. Recent innovations have led to advanced sorting and separation technologies that significantly improve efficiency. For instance, Eddy Current Separators (ECS) use rotating magnetic fields to separate non-ferrous metals from waste streams with unprecedented precision.

X-ray fluorescence (XRF) and X-ray transmission (XRT) technologies have transformed metal sorting by providing rapid and accurate identification of different metals. These high-speed, automated sorting systems can process mixed metal streams, greatly enhancing the purity and quality of recycled materials.

| Algorithm | Time Complexity (Best) | Time Complexity (Average) | Time Complexity (Worst) | Space Complexity | Stable | In-Place |

| Bubble Sort | O(n) | O(n^2) | O(n^2) | O(1) | Yes | Yes |

| Selection Sort | O(n^2) | O(n^2) | O(n^2) | O(1) | No | Yes |

| Insertion Sort | O(n) | O(n^2) | O(n^2) | O(1) | Yes | Yes |

| Merge Sort | O(n log n) | O(n log n) | O(n log n) | O(n) | Yes | No |

| Quick Sort | O(n log n) | O(n log n) | O(n^2) | O(log n) | No | Yes |

| Heap Sort | O(n log n) | O(n log n) | O(n log n) | O(1) | No | Yes |

| Counting Sort | O(n+k) | O(n+k) | O(n+k) | O(k) | Yes | No |

| Radix Sort | O(nk) | O(nk) | O(nk) | O(n+k) | Yes | No |

| Bucket Sort | O(n+k) | O(n+k) | O(n^2) | O(n) | Yes | No |

Industry 4.0 and Smart Recycling

The integration of digital tools and automation is transforming the recycling industry. Smart recycling systems, leveraging Internet of Things (IoT) technologies and machine learning algorithms, enable real-time monitoring and optimization of recycling processes. These innovations enhance operational efficiency, reduce downtime, and minimize resource waste.

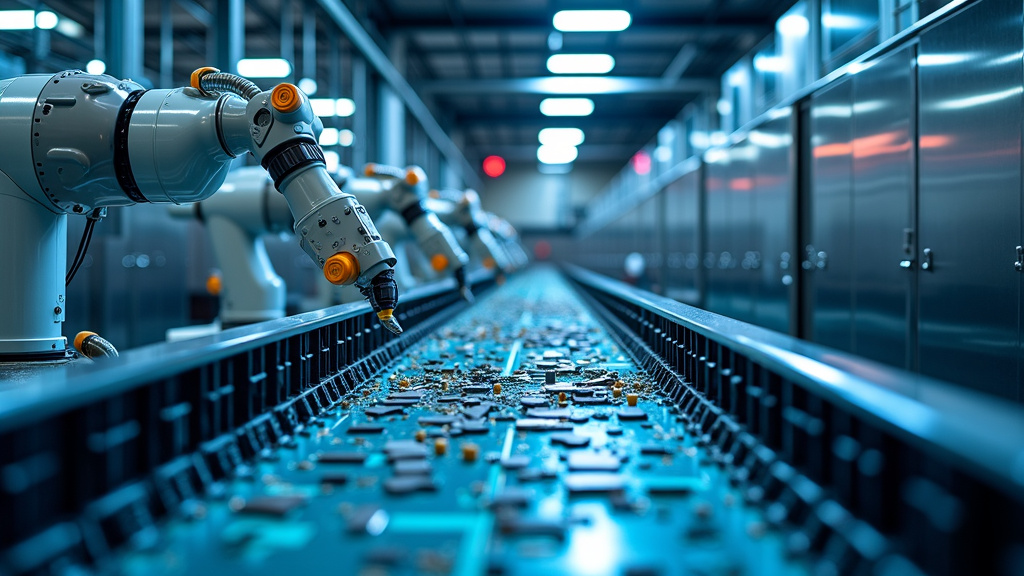

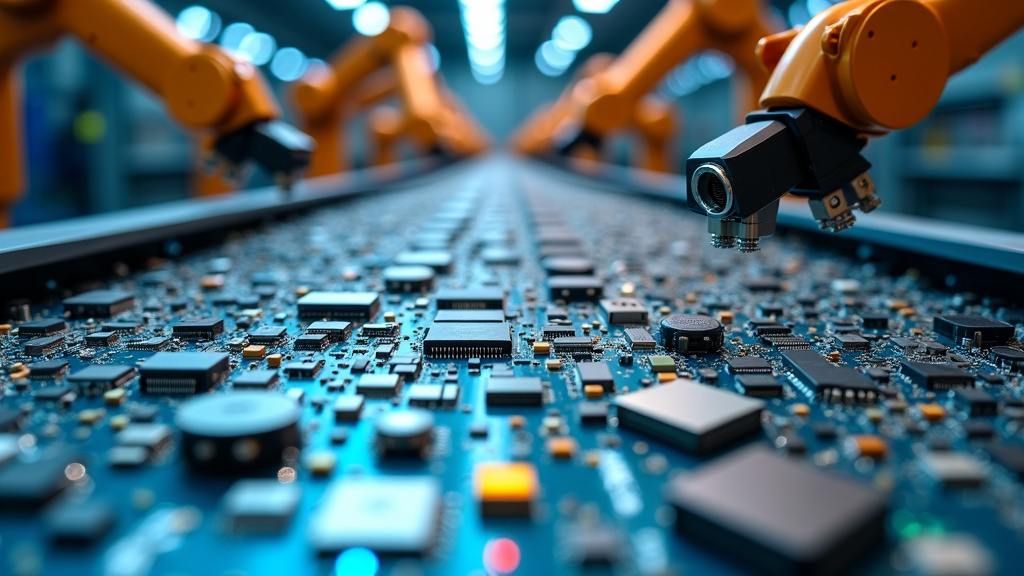

Robotics and automation are increasingly important, particularly in tasks that are hazardous or labor-intensive. Automated sorting systems equipped with advanced sensors and robotic arms can handle high volumes of mixed metal waste with precision and speed, improving both efficiency and worker safety.

Success Stories and Practical Tips

The automotive industry has made significant strides in recycling aluminum and steel from end-of-life vehicles. These efforts have conserved resources and reduced the environmental impact of vehicle production. Similarly, the electronics industry has implemented successful programs for recovering precious metals from electronic waste, contributing to resource conservation and reducing landfill waste.

For businesses looking to enhance their rare metal recycling practices, here are some practical tips:

- Invest in employee training to ensure proper identification and sorting of recyclable materials.

- Collaborate with specialized recycling partners who have expertise in rare metal recovery.

- Consider implementing a closed-loop recycling system within your manufacturing process.

- Stay informed about the latest recycling technologies and regulations in your industry.

By adopting these advanced recycling technologies and best practices, industries can significantly improve their resource efficiency, reduce waste, and contribute to a more sustainable future. As research and innovation in this field continue to advance, we can expect more efficient and environmentally friendly methods for rare metal recycling to emerge.

Challenges and Opportunities in Rare Metal Recycling

The recycling of rare metals presents a complex landscape of challenges and opportunities. As demand for these critical resources continues to surge due to technological advancements and the push for sustainable energy solutions, the need for effective recycling processes has never been more pressing. However, the path to efficient rare metal recycling is fraught with technical hurdles and economic considerations that demand innovative approaches.

One of the primary technical challenges lies in the diverse properties of rare metals and their integration into complex products. Unlike more common materials, rare metals are often used in small quantities and are intricately combined with other elements, making separation and extraction a daunting task. For instance, recovering neodymium from permanent magnets or indium from LCD screens requires sophisticated processes that can isolate these valuable elements without compromising their purity.

The economic landscape of rare metal recycling is equally challenging. High operational costs, coupled with fluctuating market prices for recycled materials, can make recycling ventures financially precarious. Moreover, the investment required for developing and implementing advanced recycling technologies can be substantial, deterring many potential stakeholders from entering the field.

Innovations Driving Progress

Despite these challenges, the field of rare metal recycling is witnessing exciting innovations that promise to overcome existing barriers. Advanced sorting technologies, such as those employing artificial intelligence and machine learning, are revolutionizing the identification and separation of rare metals from complex waste streams. These systems can rapidly and accurately sort materials, significantly improving the efficiency of recycling processes.

Hydrometallurgical processes are emerging as a game-changer in rare metal extraction. Unlike traditional pyrometallurgical methods, these water-based techniques offer more precise control over the extraction process, potentially reducing energy consumption and environmental impact. Researchers are continually refining these methods to increase yields and reduce costs, making rare metal recycling more economically viable.

Bioleaching, an innovative approach leveraging microorganisms to extract metals from ores and waste materials, is gaining traction. This eco-friendly method could potentially revolutionize rare metal recycling by providing a low-cost, low-energy alternative to conventional extraction techniques.

Regulatory Support and Future Trends

Governments worldwide are recognizing the strategic importance of rare metal recycling and are implementing supportive policies. The European Union, for instance, has introduced regulations aimed at increasing the recycling rates of electronic waste, a significant source of rare metals. These regulatory frameworks not only provide incentives for recycling initiatives but also help create a more stable market for recycled materials.

Looking ahead, the future of rare metal recycling appears promising. As technologies mature and economies of scale are achieved, the cost-effectiveness of recycling processes is likely to improve. Furthermore, the growing emphasis on circular economy principles is expected to drive innovation in product design, making future generations of electronic devices and green technologies more amenable to recycling.

The integration of digital technologies, such as blockchain, into supply chains could enhance the traceability of rare metals, ensuring the authenticity of recycled materials and potentially commanding premium prices. This increased transparency could bolster confidence in recycled rare metals, further stimulating market demand.

In conclusion, while the challenges in rare metal recycling are significant, the opportunities for innovation and environmental stewardship are equally substantial. By continuing to invest in research, fostering collaboration between industries and governments, and embracing cutting-edge technologies, we can unlock the full potential of rare metal recycling, securing a more sustainable and resource-efficient future.

| Technique | Description | Advantages | Challenges |

|---|---|---|---|

| Traditional Methods | Manual sorting, shredding, and melting. | Established processes, relatively low initial investment. | Labor-intensive, less precise, higher energy consumption. |

| Automated Sorting Systems | Use of sensors, robotics, and AI for metal separation. | Increased efficiency, improved purity and quality of recycled metals. | High initial investment, requires skilled labor. |

| Eddy Current Separation | Uses magnets to separate non-ferrous metals. | Highly efficient, processes large volumes quickly. | Limited to non-ferrous metals. |

| Hydrometallurgical Processing | Water-based chemistry to recover metals. | Environmentally friendly, reduces emissions. | Complex chemical management, potential for secondary pollution. |

| Electrochemical Recovery | Uses electric currents to dissolve and separate metals. | High purity levels, energy-efficient. | High setup cost, requires specific waste streams. |

| Laser-Induced Breakdown Spectroscopy (LIBS) | Real-time analysis of metal composition using lasers. | Rapid, accurate identification of metals. | Technical complexity, requires specialized equipment. |

Conclusion: Towards a Sustainable Future

Efficient rare metal recycling is crucial for resource conservation and sustainability. As industries face resource scarcity and environmental challenges, innovative solutions are essential. Okon Recycling is at the forefront, pioneering advanced recycling methods to maximize material recovery and reduce waste.

Recycling rare earth metals saves up to 95% of the energy needed for raw material extraction, significantly cutting emissions and preserving finite resources. Okon Recycling’s Dallas facility is setting new industry standards, transforming scrap into valuable materials while promoting a circular economy.

With advancing recycling technologies and growing industry adoption, the future of rare metal recovery is promising. These innovations not only benefit the environment but also create economic opportunities—from job growth in the recycling sector to cost savings for businesses embracing sustainable practices.

Sustainability starts with action. By supporting Okon Recycling, we invest in a cleaner, more resource-efficient future. To learn more about their rare metal recycling solutions, contact 214-717-4083 today. Together, we can reshape resource management for a greener tomorrow.