5901 Botham Jean Blvd, Dallas, TX 75215

The Environmental Benefits of Recycling Old Chillers

February 3, 2025Improperly disposed industrial chillers can leak harmful substances, potentially contaminating groundwater and contributing to environmental degradation. This reality underscores the importance of responsible recycling practices for these large-scale cooling systems.

Welcome to the world of chiller recycling, where environmental stewardship meets industrial innovation. As businesses and facilities upgrade their cooling infrastructure, the fate of outdated chillers becomes a pressing concern. Fortunately, companies like Okon Recycling are leading the charge in transforming what could be hazardous waste into valuable resources.

Recycling old chillers is not just about clearing space in landfills—though that is certainly a significant benefit. It is about conserving energy, preserving raw materials, and protecting our planet’s delicate ecosystems. When we recycle these industrial giants, we are not just disposing of metal and refrigerants; we are investing in a more sustainable future.

Imagine the impact: every recycled chiller means less mining for new metals, reduced energy consumption in manufacturing, and a significant decrease in potentially harmful emissions. It is a ripple effect that touches every aspect of our environment, from the air we breathe to the water we drink.

Comprehensive Recycling Solutions for Industrial Chillers

Industrial chillers are vital components in many manufacturing and processing facilities, tirelessly maintaining optimal temperatures for various applications. When these complex machines reach the end of their operational life, they present a unique recycling challenge and opportunity.

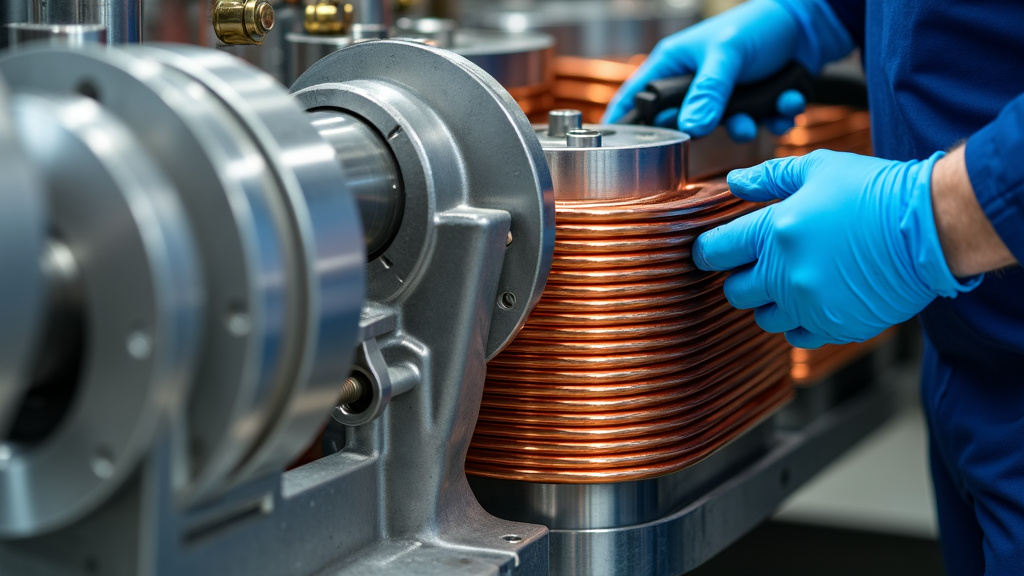

At the core of every industrial chiller is a wealth of recyclable materials. Steel, the backbone of these robust units, and copper, essential for their electrical systems, are prime candidates for recycling. However, the process isn’t as simple as placing these components in a recycling bin.

Enter Okon Recycling, a company at the forefront of metal recycling for over a century. Their approach to industrial chiller recycling is innovative. “We don’t just recycle; we reimagine the entire process,” says Louis Okon, spokesperson for the company. “Each chiller is a puzzle we’re eager to solve, ensuring maximum resource recovery and minimal environmental impact.”

The Recycling Process: A Symphony of Sustainability

Okon’s process begins with a meticulous assessment of each chiller unit. Technicians carefully dismantle the chiller, separating components based on material composition. It’s a far cry from the crude ‘crush and sort’ methods of the past.

Steel, often comprising the bulk of a chiller’s weight, is sorted and processed for remelting, leading to significant energy savings. According to industry studies, recycling steel requires 60% less energy than producing new steel from raw materials.

Copper, a critical component in electrical systems and heat exchangers, is another prized material. Its recycling not only conserves natural resources but also reduces the need for environmentally damaging mining operations. “Copper recycling is a win-win,” Okon explains. “It’s valuable for us and invaluable for the planet.”

Beyond Metal: A Holistic Approach to Chiller Recycling

Okon’s expertise extends beyond metal recycling. They have developed processes to handle refrigerants, oils, and other potentially harmful substances found in chillers. These materials are carefully extracted and either recycled or disposed of in environmentally responsible ways.

This comprehensive approach ensures that virtually every part of the chiller finds new life or is disposed of safely, setting Okon apart in the industrial recycling landscape.

The Business Case for Chiller Recycling

While the environmental benefits of chiller recycling are clear, there are also economic advantages. The raw materials recovered from chillers can offset the costs of decommissioning and disposal. In some cases, companies have even turned a profit on their obsolete equipment through Okon’s services.

Looking to the Future

As industries continue to grapple with the dual challenges of resource scarcity and environmental responsibility, companies like Okon Recycling are leading the way in innovative solutions. Their approach to industrial chiller recycling demonstrates that sustainability and profitability can go hand in hand.

For businesses looking to dispose of old chiller units responsibly and potentially recover value in the process, Okon Recycling’s tailored solutions offer a compelling option. It’s a shining example of how effective recycling techniques can be both sustainable and cost-efficient for businesses of all sizes.

| Benefit | Description |

| Energy Conservation | Recycling reduces the need for new raw material extraction, saving energy. |

| Landfill Waste Reduction | Recycling chillers significantly reduces landfill waste. |

| Resource Preservation | Conserves raw materials like steel and copper by recycling existing components. |

| Environmental Protection | Prevents harmful substances from contaminating the environment. |

| Economic Value | Recovered materials can offset disposal costs and generate revenue. |

Efficient Disposal Strategies for Old Chillers

As businesses upgrade their cooling systems, the question of what to do with old chillers becomes increasingly pressing. It’s not just about getting rid of outdated equipment; it’s about responsible disposal that considers environmental impact and regulatory compliance. Let’s explore how companies can navigate this process effectively.

Why is proper chiller disposal crucial? These massive cooling units often contain refrigerants that, if released into the atmosphere, can cause significant environmental harm, including ozone depletion and increased greenhouse gas emissions.

So, how do you dispose of an old chiller correctly? It’s not as simple as calling your local junk removal service. There’s a method to this process, and it starts with a thorough assessment.

Step 1: Assess Your Chiller

Before doing anything else, evaluate your chiller. Is it completely defunct, or could it potentially be refurbished and reused? Sometimes, what seems like a lost cause can be given a second life with the right repairs.

If refurbishment isn’t an option, it’s time to move on to disposal. But don’t rush—this is where expertise really comes in handy.

Okon Recycling, for instance, specializes in this kind of assessment. Their team can quickly determine whether your chiller is a candidate for recycling or if it needs more specialized disposal methods.

Step 2: Refrigerant Recovery

Here’s where environmental responsibility is critical. The refrigerants in your chiller need to be carefully removed and captured. This isn’t just good practice; it’s mandated by EPA regulations.

Certified technicians use specialized equipment to extract these refrigerants safely. It’s a delicate process that requires expertise and precision. One wrong move, and you could face a hefty fine for environmental violations.

Okon Recycling’s team is well-versed in this process, ensuring that every drop of refrigerant is properly captured and disposed of or recycled according to current regulations.

Step 3: Disassembly and Recycling

Once refrigerants are safely removed, it’s time to break down the chiller into its component parts. This isn’t just about making the unit easier to transport; it’s about maximizing recycling potential.

Chillers contain a variety of materials—metals, plastics, and electronic components. Each of these can often be recycled or repurposed, reducing waste and conserving resources. It’s like a giant puzzle, where each piece has its own recycling journey.

Okon Recycling’s facilities are equipped to handle this complex disassembly process. They ensure that each component finds its way to the appropriate recycling stream, maximizing the environmental benefits of your disposal efforts.

| Component | Function |

| Compressor | Creates pressure difference to move refrigerant |

| Condenser | Removes heat from refrigerant |

| Evaporator | Collects unwanted heat from the building |

| Expansion Valve | Expands refrigerant to reduce pressure |

| Power Panel | Controls electrical power flow |

| Controls Unit | Monitors and adjusts chiller performance |

| Water Box | Directs water flow in evaporators and condensers |

Step 4: Documentation and Compliance

In industrial waste management, documentation is crucial. You need to prove that you’ve disposed of your chiller responsibly. This isn’t just about covering your bases; it’s about complying with environmental regulations.

Proper documentation includes records of refrigerant recovery, details of the recycling process, and confirmation that all components were handled according to current regulations. It’s a paper trail that protects your business from potential legal issues.

This is where partnering with a company like Okon Recycling pays off. They handle all the necessary paperwork, ensuring you have a complete record of your chiller’s disposal journey.

Checklist for Businesses: Efficient Chiller Disposal

- Assess the chiller’s condition—Can it be refurbished or must it be disposed of?

- Contact a certified disposal service like Okon Recycling for professional assessment

- Ensure proper refrigerant recovery by certified technicians

- Oversee the disassembly process, confirming all components are properly sorted

- Obtain detailed documentation of the entire disposal process

- Verify compliance with all relevant environmental regulations

- Consider the recycling potential of each component

- Keep records of the disposal for future reference

Disposing of an old chiller might seem daunting, but with the right partner, it can be a smooth, environmentally responsible process. Companies like Okon Recycling bring expertise, facilities, and regulatory knowledge to the table, simplifying what could otherwise be a complex and risky undertaking.

By following these strategies and working with experienced professionals, businesses can ensure their old chillers don’t become environmental liabilities. Instead, they can be part of a sustainable cycle, where materials are recycled, regulations are met, and environmental impact is minimized. It’s not just good for the planet; it’s good business sense too.

Concluding Thoughts on Recycling Large-Scale Industrial Materials

Throughout this article, we’ve explored how recycling large-scale industrial materials is not just a trend but a critical necessity for environmental stewardship. The impact of these efforts extends beyond waste reduction, encompassing resource conservation, energy savings, and the mitigation of environmental pollution.

Innovative practices in industrial recycling are transforming what was once considered waste into valuable, reusable resources. This shift is not only environmentally responsible but also economically wise. Companies like Okon Recycling are leading this transformation, demonstrating how advanced technologies and methodologies can change our approach to industrial waste management.

The benefits of sustainable recycling in the industrial sector are multifaceted. From reducing landfill usage to conserving natural resources, these practices are essential in combating climate change and environmental degradation. Moreover, they create jobs, stimulate economic growth, and foster innovation in waste management and resource recovery.

Ready to make a positive impact? Reach out to Okon Recycling today and be part of the solution in building a sustainable energy future. For more information contact us at 214-736-9509.